Unit - 3

Strength of concrete

Q1) What is Strength of concrete?

A1)

- Methods and system for the manufacturing of concrete are constantly being modernized. Testing methods, at the side of records interpretation, too are upgrading and getting extra sophisticated.

- But the best of concrete is on the whole primarily based totally on its electricity. It is the electricity of concrete that bureaucracy the idea of attractiveness or rejection of concrete in production. Specific codes are designate to signify the equal for distinct structures.

- The first-ground columns in high-upward thrust buildings, for instance, are structurally extra essential than nonbearing walls. A deficiency withinside the required electricity can cause costly, dangerous, and difficult maintenance or, at worst, cause a massive failure.

- So obviously, the general electricity of any production holds great importance, however the diploma relies upon on its structural elements. Considering the electricity specifications is likewise essential even as estimating the proposed mix, because the predicted proportions rely on the intended electricity for finalizing the ingredients’ properties.

- Compressive Strength Of Concrete: Compressive electricity is a broadly conventional degree to get admission to the overall performance of a given concrete mixture.

- Considering this element of concrete is crucial due to the fact it's miles the number one degree figuring out how nicely concrete can face up to masses that have an effect on its length. It appropriately tells you whether or not or now no longer a selected blend is appropriate to satisfy the necessities of a selected project. Concrete can excellently withstand compressive loading. This is why it's miles appropriate for building arches, columns, dams, foundations, and tunnel linings.

- Concrete’s compressive electricity is ascertained with cylindrical specimens made from clean concrete. It is then examined in compression at numerous ages. The length and form may additionally have an effect on the indicated electricity. Additional assessments are similarly carried out to achieve distinct statistics at the competence of electricity development. Usually, the compressive electricity of concrete varies from 2500 psi (17 MPa) to 4000 psi (28 MPa) and better in residential and business structures. Several programs additionally make use of strengths extra than 10,000 psi (70 MPa).

- Tensile Strength Of Concrete: The tensile energy of concrete is its ability to face up to cracking or breaking beneathneath anxiety. Although concrete is not often loaded beneathneath natural strain in a shape, figuring out the tensile energy is important to apprehend the quantity of the viable damage. Breaking and cracking get up while tensile forces surpass the tensile energy.

- Compared to the ultra-excessive overall performance concrete, conventional concrete has highly excessive compressive energy in comparison to tensile energy, that is appreciably lower.

- This shows that any concrete shape which could go through tensile pressure ought to first be strengthened with excessive tensile energy substances like steel.

- The understanding approximately the tensile energy of concrete is an increasing number of getting full-size because of its importance in dealing with capacity cracking.

- However, checking out the tensile energy of concrete is relatively tricky – in fact, there's no discipline check for direct judgment. But, oblique techniques like splitting are pretty helpful. Studies imply that conventional concrete’s tensile energy varies among three hundred and seven hundred psi, i.e., round 2 to five MPa. This means, on average, the anxiety averages approximately 10% of the compressive energy.

Q2) Explain gain of strength

A2)

- As in keeping with research and researches, the compressive electricity of the concrete will growth with age. Most researches had been carried out to examine the twenty eighth-day electricity of concrete.

- But in reality, the electricity at twenty eighth day is much less in comparison to the long-time period electricity that it could advantage with age. The concrete electricity version with age may be studied with the aid of using distinctive methods. T

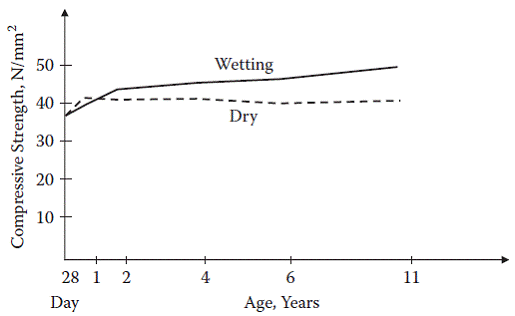

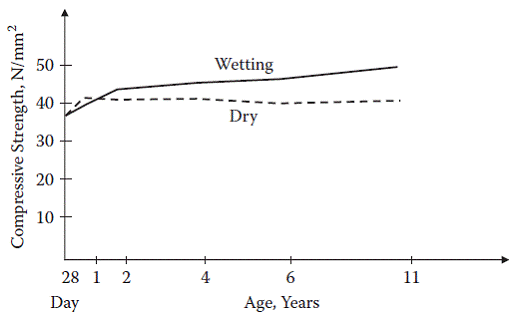

- The figure-1 underneath indicates the electricity version of a concrete gift at dry and moist condition. This graph is primarily based totally at the examine carried out with the aid of using Baykof and Syglof (1976). They determined that, in dry conditions, after 1 yr there's no growth in concrete electricity, as proven in figure-1. On the opposite hand, the electricity of specimens saved in a moist environment (at 15°C) is extensively increased.

Q3) What is wet ratio?

A3)

- In order to discover the drying–wetting cycle take a look at approach of concrete beneathneath sulfate accelerating erosion, the have an impact on of dry–moist time ratio on concrete sulfate erosion changed into studied. Under the circumstance of seven days for one cycle, 5 distinct dry–moist time ratios had been designed: 1:3, 1:1, 3:1, 5:1, and 10:1.

- The fundamental residences which includes compressive energy, splitting tensile energy and dynamic elastic modulus of concrete had been tested. Scanning electron microscopy (SEM) changed into used to investigate the microstructure of concrete earlier than and after erosion.

- The take a look at consequences display that beneathneath the surroundings of sulfate drying–wetting cycle erosion, the extrade of mechanical residences of concrete are divided into 3 stages: ascending duration, fluctuating duration and fast descending duration.

- Concrete is subjected to periodic harm manner of preliminary harm accompanied with the aid of using filling compaction, cracking, similarly filling, and cracking again, in that order. Dry–moist ratio has a good sized impact on concrete sulfate assault.

- Under the identical drying–wetting cycle duration, because the dry–moist ratio will increase, the diploma of degradation of concrete with the aid of using sulfate assault will increase first after which decreases. When the dry–moist ratio is 5:1, the deterioration is the maximum serious.

Q4) Explain factor affecting compressive strength.

A4)

- Concrete energy is suffering from many factors, inclusive of excellent of uncooked materials, water/cement ratio, coarse/exceptional mixture ratio, age of concrete, compaction of concrete, temperature, relative humidity and curing of concrete.

- Quality of Raw Materials Cement: Provided the cement conforms with the right preferred and it's been saved correctly (i.e. in dry conditions), it must be appropriate to be used in concrete.

- Aggregates: Quality of aggregates, its size, shape, texture, energy and so forth determines the energy of concrete. The presence of salts (chlorides and sulphates), silt and clay additionally reduces the energy of concrete. Water: often the best of the water is blanketed with the aid of using a clause stating “..the water must be match for drinking..”. This criterion aleven though isn't always absolute and reference must be made to respective codes for checking out of water production purpose.

- Aggregate / Cement Ratio: Following factors should be stated for combination cement ratio: If the extent stays the equal and the share of cement in terms of that of sand is improved the floor place of the strong will growth. If the floor place of the solids has improved, the water call for will live the equal for the consistent workability. Assuming a growth in cement content material for no growth in water call for, the water cement ratio will decrease. If the water cement ratio reduces, the power of the concrete will growth.

- Coarse / quality combination ratio: Following factors need to be mentioned for coarse/quality combination ratio: If the percentage of fines is accelerated on the subject of the coarse combination, the general combination floor region will increase. If the floor region of the combination has accelerated, the water call for will even increase. Assuming the water call for has accelerated, the water cement ratio will increase. Since the water cement ratio has accelerated, the compressive electricity will decrease.

Q5) Define w/c ratio.

A5)

- Water / Cement Ratio The better the water/cement ratio, the more the preliminary spacing among the cement grains and the more the quantity of residual voids now no longer stuffed with the aid of using hydration products. There is one aspect lacking at the graph.

- For a given cement content, the workability of the concrete is decreased if the water/cement ratio is decreased. A decrease water cement ratio manner much less water, or extra cement and decrease workability. However if the workability turns into too low the concrete turns into tough to compact and the power reduces.

- For a given set of substances and surroundings conditions, the power at any age relies upon handiest at the water-cement ratio, presenting complete compaction may be achieved.

Q6) Explain type of cement.

A6)

- Types of Cement: The distinctive varieties of cement come from including numerous elements and converting the proportions of elements. These additions and modifications permit cement for use in the whole lot from preferred creation paintings to sulfate-resistant packages like sewage systems.

- Portland cement is handiest one in all 5 simple varieties of cement diagnosed through ASTM, the overall listing consists of: Type 1 is regular Portland cement (OPC), that is a preferred-use material.

- Type 2 has slight sulfate resistance, and its MH version is fairly proof against warmth of hydration. It’s utilized in systems so one can come into touch with sulfate in water or soil.

- Type three cement is an additional fast hardening cement. Most concrete takes approximately a month to get to its complete power after it's far poured; this cement turns into tougher greater quickly.

- Type four is a low warmth cement that radiates much less warm temperature because it units and dries. It’s used for packages in which an excessive amount of warmth is undesirable.

- Type five cement is particularly sulfate resistant, used for touch with excessive alkaline soil and water. Other cement sorts you can run into include: Types 1A, 2A, and 3A, which might be editions of kind 1, 2, and three cements.

- These varieties of cement have air-entraining substances jumbled in to lead them to proof against moisture damage. Types IL (Portland-limestone), IS (Portland-slag cement), IT (ternary blended), and IP (Portland pozzolana) cement, which might be hydraulic and feature unique properties.

- IS cement, usually referred to as slag cement, consists of granulated blast furnace slag and is frequently used to update a part of the portland cement going into the concrete. Type GU, HE, MS, HS, MH, and LH cements, whose names talk to their properties. GU stands for preferred use, HE for excessive early power, and MS and HS for slight and excessive sulfate resistance. Similarly, MH and LH talk to cement sorts with slight and excessive warmth of hydration.

Q7) What is air entrainment?

A7)

- Air entrainment in concrete is the intentional introduction of tiny air bubbles in a batch with the aid of using including an air entraining agent at some point of mixing. A shape of surfactant (a floor-energetic substance that during the example reduces the floor anxiety among water and solids) it lets in bubbles of a favored length to shape.

- These are created at some point of concrete mixing (at the same time as the slurry is in its liquid state), with maximum surviving to stay a part of it whilst hardened.

- Though hardened concrete seems as a compact solid, it's miles in reality surprisingly porous (regular concrete porosity: ~ 6 – 12 vol.%), having small capillaries because of the evaporation of water past that required for the hydration reaction.

- A water to cement ratio (w/c) of about 0.38 (this indicates 38 lbs. Of water for each one hundred lbs. Of cement) is needed for all of the cement debris to hydrate.

- Water past this is surplus and is used to make the plastic concrete greater viable or effortlessly flowing or much less viscous. To gain a appropriate stoop to be viable, maximum concrete has a w/c of 0.forty five to 0.60 on the time of placement, because of this that there may be large extra water so as to now no longer react with cement.

- When the extra water evaporates it leaves little pores in its place. Environmental water can later fill those voids thru capillary action. During freeze-thaw cycles, the water occupying the ones pores expands and creates tensile stresses which result in tiny cracks.

- These cracks permit greater water into the concrete and the cracks enlarge. Eventually the concrete spalls – chunks spoil off. The failure of bolstered concrete is most customarily because of this cycle, that's extended via way of means of moisture attaining the reinforcing steel, inflicting it to rust, expand, create greater cracks, permit in greater water, and worsen the decomposition cycle.

Q8) Explain aggregates in detail.

A8)

- Aggregates are inert granular substances inclusive of sand, gravel, or overwhelmed stone that, along side water and portland cement, are an critical component in concrete.

- For a very good concrete mix, aggregates want to be clean, hard, robust debris freed from absorbed chemical compounds or coatings of clay and different exceptional substances that would purpose the deterioration of concrete.

- Aggregates, which account for 60 to seventy five percentage of the overall extent of concrete, are divided into wonderful categories--exceptional and coarse. Fine aggregates typically encompass herbal sand or overwhelmed stone with maximum debris passing via a 3/eight-inch sieve. Coarse aggregates are any debris more than 0.19 inch, however typically variety among 3/eight and 1.five inches in diameter. Gravels represent the bulk of coarse mixture utilized in concrete with overwhelmed stone making up maximum of the remainder.

- Natural gravel and sand are commonly dug or dredged from a pit, river, lake, or seabed. Crushed mixture is produced through crushing quarry rock, boulders, cobbles, or large-length gravel. Recycled concrete is a feasible supply of mixture and has been satisfactorily utilized in granular subbases, soil-cement, and in new concrete.

- After harvesting, mixture is processed: overwhelmed, screened, and washed to gain right cleanliness and gradation. If necessary, a benefaction procedure inclusive of jigging or heavy media separation may be used to improve the quality. Once processed, the aggregates are dealt with and saved to reduce segregation and degradation and save you contamination.

- Aggregates strongly affect concrete's freshly combined and hardened residences, aggregate proportions, and economy. Consequently, choice of aggregates is a crucial procedure.

- Although a few version in mixture residences is expected, traits which can be taken into consideration include: grading durability particle form and floor texture abrasion and skid resistance unit weights and voids absorption and floor moisture

Q9) What is mixing water?

A9)

- The key to attaining a strong, long lasting concrete rests withinside the cautious proportioning and combining of the ingredients.

- A combination that doesn't have sufficient paste to fill all of the voids among the aggregates could be hard to area and could produce hard surfaces and porous concrete. A combination with an extra of cement paste could be clean to area and could produce a clean surface; however, the ensuing concrete isn't cost-powerful and may extra without problems crack. Portland cement's chemistry involves lifestyles withinside the presence of water. Cement and water shape a paste that coats every particle of stone and sand—the aggregates.

- Through a chemical response known as hydration, the cement paste hardens and profits energy. The exceptional of the paste determines the man or woman of the concrete. The energy of the paste, in turn, relies upon at the ratio of water to cement.

- The water-cement ratio is the load of the combination water divided through the load of the cement. High-exceptional concrete is produced through reducing the water-cement ratio as an awful lot as feasible with out sacrificing the workability of clean concrete, permitting it to be well placed, consolidated, and cured.

- A well designed combination possesses the preferred workability for the clean concrete and the specified sturdiness and energy for the hardened concrete. Typically, a combination is set 10 to fifteen percentage cement, 60 to seventy five percentage combination and 15 to twenty percentage water. Entrained air in lots of concrete mixes may additionally absorb any other five to eight percentage.

Q10) Define admixtures.

A10)

- Concrete, the unmarried maximum widely-used constructing cloth withinside the world, has a records courting again to the Romans and historic Egyptians. Given that concrete is used two times as a good deal in creation over all different constructing materials, emphasis on quality, overall performance and sustainability is critical for the enterprise to develop and thrive.

- One of the maximum vital elements in excessive overall performance, long-lasting, long lasting and delightful concrete produced these days are concrete admixtures. Concrete admixtures are herbal or synthetic chemical compounds or components brought for the duration of concrete blending to decorate unique houses of the clean or hardened concrete, which include workability, durability, or early and very last strength.

- The first step in optimizing concrete is to recognize that concrete is no longer simply cementitious materials, aggregates and water. It is a high performance material with not just four, but seven essentials – consisting of water, cementitious material, sand, gravel, chemical admixtures, additives and fiber reinforcement.

Q11) What is curing conditions?

A11)

- Curing performs a critical function on power improvement and sturdiness of concrete. Curing takes location straight away after concrete setting and finishing, and includes renovation of preferred moisture and temperature conditions, each at intensity and close to the surface, for prolonged durations of time.

- Properly cured concrete has a good enough quantity of moisture for endured hydration and improvement of power, quantity stability, resistance to freezing and thawing, and abrasion and scaling resistance. The duration of good enough curing time is depending on the subsequent factors: Mixture proportions Specified power Size and form of concrete member Ambient climate conditions Future publicity conditions

- Slabs on ground (e.g. Pavements, sidewalks, parking lots, driveways, floors, canal linings) and structural concrete (e.g. Bridge decks, piers, columns, beams, slabs, small footings, cast-in-vicinity walls, keeping walls) require a minimal curing duration of 7 days for ambient temperatures above forty levels Fahrenheit1.

- American Concrete Institute (ACI) Committee 301 recommends a minimal curing duration similar to concrete accomplishing 70 percentage of the desired compressive strength2. The frequently unique seven-day curing typically corresponds to about 70 percentage of the desired compressive strengths.

- The 70 percentage energy stage may be reached faster whilst concrete remedies at better temperatures or whilst sure cement/admixture combos are used. Similarly, longer time can be wished for unique cloth combos and/or decrease curing temperatures. For this reason, ACI Committee 308 recommends the subsequent minimal curing periods

Q12) Explain tensile and flexural strength of concrete.

A12)

Tensile Strength Of Concrete

- The tensile electricity of concrete is its potential to face up to cracking or breaking beneathneath anxiety. Although concrete is not often loaded beneathneath natural stress in a shape, f

- Iguring out the tensile electricity is vital to apprehend the volume of the viable damage. Breaking and cracking get up whilst tensile forces surpass the tensile electricity. Compared to the ultra-excessive overall performance concrete, conventional concrete has noticeably excessive compressive electricity as compared to tensile electricity, that is notably lower. This shows that any concrete shape which can go through tensile pressure have to first be strengthened with excessive tensile electricity substances like steel. The expertise approximately the tensile electricity of concrete is an increasing number of getting massive because of its importance in coping with ability cracking.

- However, trying out the tensile electricity of concrete is relatively tricky – in fact, there's no area take a look at for direct judgment. But, oblique strategies like splitting are pretty helpful. Studies imply that conventional concrete’s tensile electricity varies among three hundred and seven hundred psi, i.e., round 2 to five MPa. This means, on average, the anxiety averages approximately 10% of the compressive electricity.

Flexural Strength Of Concrete

- Flexural energy establishes the capacity of concrete to resist bending. It is an oblique degree of tensile energy. Let us apprehend flexure energy with this conventional example – numerous structures, consisting of pavements, slabs, and beams, and its additives are difficulty to bending or flexure.

- Talking of a beam, it could be loaded on the middle and be supported on the ends. Its backside fibers are in tension, while higher ones are in compression. If this beam is built with concrete, it's going to revel in a tensile failure withinside the decrease fibers due to the fact concrete has a weaker tension. However, consisting of some metal bars withinside the decrease place will maintain a greater full-size load because the reinforcing metal has excessive tensile energy.

- In fact, if the reinforcing metal is pre-careworn in concrete, the beam will nevertheless be strong.

- The flexural energy of concrete is typically decided via way of means of trying out a easy beam in which the focused load is implemented at every of the 1/3 points. The numbers are then expressed in a Modulus of Rupture (MR) in psi. Depending at the unique concrete mix, flexural energy is preferably everywhere among 10% and 15% of the compressive energy.

Q13) Explain relation between cracking in compression.

A13)

- Concrete is the maximum not unusualplace constructing cloth across the world. Since the discovery of contemporary-day cement with the aid of using Louis Vicat in 1817, studies and improvement efforts have progressed its properties: packages were progressed, mechanical energy and chemical concrete-crack-bodyresistance were expanded and new substances consisting of pre-confused concrete were developed.

- Has concrete grow to be best over the years? Looking cautiously at the numerous concrete systems that surround us, even along with the maximum current buildings, we see that now no longer any such systems is flawlessly intact. This highlights the unavoidable weak point of concrete: its tendency to crack.

- Cracking is exacerbated with the aid of using the thing which made concrete so popular: its compatibility with steel, and the cappotential of strengthened concrete to satisfy the necessities for a sophisticated constructing cloth.

- However, are cracks all of the same? Certainly now no longer! In fact, cracks may be because of numerous various factors consisting of deformation, hydraulic shrinkage, thermal shrinkage or swelling.

Q14) What is impact strength?

A14)

Impact strength

- Predicting the effect resistance of concrete and bolstered concrete systems has been of hobby for lots years. Constitutive fashions that account for stress price consequences, excessive pressure, and the related dynamic electricity growth are the important thing to a success predictions.

- Constitutive fashions accounting for stress price consequences may be labeled into harm fashions, plasticity fashions, and harm-plasticity fashions. Damage fashions for concrete accounting for excessive stress prices have been evolved, for instance.

- A famous plasticity version for concrete became proposed by as an extension of the Johnson-Cook version in the beginning evolved for metals. In this version, the dynamic electricity growth became associated with the modern-day stress price.

- However, reminiscence consequences have been now no longer accounted for. Furthermore, discontinuities withinside the stress-stress reaction is allowed which might be bodily now no longer meaningful. In, the dynamic buckling electricity became consequently depending on the stress price records and a mean stress price.

- A viscous harm-plasticity version accounting for excessive stress prices and excessive pressures became proposed by. Therefore, a dynamic harm variable became added that decayed the static harm evolution. The decaying feature relies upon on preceding harm-prices or harm increments. The scalar harm became in a while prolonged to a harm tensor accounting for the anisotropy for concrete below tensile loading at the same time as a scalar harm became maintained in compression.

Q15) What is fatigue strength?

A15)

- For many structural engineers, the problem of fatigue evaluation has been restrained to three simplified opinions primarily based totally at the American Institute of Steel Construction (AISC) Steel Construction Manual that asserts much less than 2,000,000 cycles implies no problem.

- For concrete structures, the presumption of any fatigue loss changed into by no means even a layout attention in normal coursework or practice.

- Therefore, expert structural engineers withinside the U.S. Have by no means definitely been educated in know-how the consequences of fatigue and fracture mechanics, besides Northridge Earthquake’s effect on welded metallic second body connections. T

- The commercial age (1920 to 1960) noticed a proliferation of latest buildings, bridges, and infrastructure factors constructed below this methodology. As the career maintains to conform into greater esoteric, analytical, and targeted areas, structural engineers understand that the problem of fatigue is greater than only a textbook dialogue and has very actual implications at the long time issues of structures. Structures are actually passing 50 years. S

- Ome have nicely over a hundred years of provider existence and are starting to expose intense symptoms and symptoms of long-time period put on and tear. This is specially genuine of bridges of each metallic and urban in which cracking, corrosion, and fractures are proscribing the prolonged existence of those important arteries of our economy.

- Why is fatigue evaluation important? Here are the essential reasons: Fatigue loading ends in fractures, cracking, and eventual collapse/failure due to the fact the shape will probable fail earlier than it reaches its yield point. Even aleven though the shape is elastic, it nevertheless poses a existence-protection risk to occupants.

- Designing for energy, ductility, dynamic response, stress compatibility, and serviceability are essential however haven't any correlation to fatigue evaluation. A shape may be compliant with all the simple tenets of structural layout and nevertheless fail in fatigue.

- Increasing the energy (i.e. yield energy/stiffness) does now no longer always make a contribution to higher fatigue energy. Fatigue failure is the end result of a excessive quantity of cycles with low to mild pressure over an prolonged duration that finally fractures the cloth and reasons failure.

- These fractures will develop and in the long run undermine the structural energy of the member and the system.

Unit - 3

Strength of concrete

Q1) What is Strength of concrete?

A1)

- Methods and system for the manufacturing of concrete are constantly being modernized. Testing methods, at the side of records interpretation, too are upgrading and getting extra sophisticated.

- But the best of concrete is on the whole primarily based totally on its electricity. It is the electricity of concrete that bureaucracy the idea of attractiveness or rejection of concrete in production. Specific codes are designate to signify the equal for distinct structures.

- The first-ground columns in high-upward thrust buildings, for instance, are structurally extra essential than nonbearing walls. A deficiency withinside the required electricity can cause costly, dangerous, and difficult maintenance or, at worst, cause a massive failure.

- So obviously, the general electricity of any production holds great importance, however the diploma relies upon on its structural elements. Considering the electricity specifications is likewise essential even as estimating the proposed mix, because the predicted proportions rely on the intended electricity for finalizing the ingredients’ properties.

- Compressive Strength Of Concrete: Compressive electricity is a broadly conventional degree to get admission to the overall performance of a given concrete mixture.

- Considering this element of concrete is crucial due to the fact it's miles the number one degree figuring out how nicely concrete can face up to masses that have an effect on its length. It appropriately tells you whether or not or now no longer a selected blend is appropriate to satisfy the necessities of a selected project. Concrete can excellently withstand compressive loading. This is why it's miles appropriate for building arches, columns, dams, foundations, and tunnel linings.

- Concrete’s compressive electricity is ascertained with cylindrical specimens made from clean concrete. It is then examined in compression at numerous ages. The length and form may additionally have an effect on the indicated electricity. Additional assessments are similarly carried out to achieve distinct statistics at the competence of electricity development. Usually, the compressive electricity of concrete varies from 2500 psi (17 MPa) to 4000 psi (28 MPa) and better in residential and business structures. Several programs additionally make use of strengths extra than 10,000 psi (70 MPa).

- Tensile Strength Of Concrete: The tensile energy of concrete is its ability to face up to cracking or breaking beneathneath anxiety. Although concrete is not often loaded beneathneath natural strain in a shape, figuring out the tensile energy is important to apprehend the quantity of the viable damage. Breaking and cracking get up while tensile forces surpass the tensile energy.

- Compared to the ultra-excessive overall performance concrete, conventional concrete has highly excessive compressive energy in comparison to tensile energy, that is appreciably lower.

- This shows that any concrete shape which could go through tensile pressure ought to first be strengthened with excessive tensile energy substances like steel.

- The understanding approximately the tensile energy of concrete is an increasing number of getting full-size because of its importance in dealing with capacity cracking.

- However, checking out the tensile energy of concrete is relatively tricky – in fact, there's no discipline check for direct judgment. But, oblique techniques like splitting are pretty helpful. Studies imply that conventional concrete’s tensile energy varies among three hundred and seven hundred psi, i.e., round 2 to five MPa. This means, on average, the anxiety averages approximately 10% of the compressive energy.

Q2) Explain gain of strength

A2)

- As in keeping with research and researches, the compressive electricity of the concrete will growth with age. Most researches had been carried out to examine the twenty eighth-day electricity of concrete.

- But in reality, the electricity at twenty eighth day is much less in comparison to the long-time period electricity that it could advantage with age. The concrete electricity version with age may be studied with the aid of using distinctive methods. T

- The figure-1 underneath indicates the electricity version of a concrete gift at dry and moist condition. This graph is primarily based totally at the examine carried out with the aid of using Baykof and Syglof (1976). They determined that, in dry conditions, after 1 yr there's no growth in concrete electricity, as proven in figure-1. On the opposite hand, the electricity of specimens saved in a moist environment (at 15°C) is extensively increased.

Q3) What is wet ratio?

A3)

- In order to discover the drying–wetting cycle take a look at approach of concrete beneathneath sulfate accelerating erosion, the have an impact on of dry–moist time ratio on concrete sulfate erosion changed into studied. Under the circumstance of seven days for one cycle, 5 distinct dry–moist time ratios had been designed: 1:3, 1:1, 3:1, 5:1, and 10:1.

- The fundamental residences which includes compressive energy, splitting tensile energy and dynamic elastic modulus of concrete had been tested. Scanning electron microscopy (SEM) changed into used to investigate the microstructure of concrete earlier than and after erosion.

- The take a look at consequences display that beneathneath the surroundings of sulfate drying–wetting cycle erosion, the extrade of mechanical residences of concrete are divided into 3 stages: ascending duration, fluctuating duration and fast descending duration.

- Concrete is subjected to periodic harm manner of preliminary harm accompanied with the aid of using filling compaction, cracking, similarly filling, and cracking again, in that order. Dry–moist ratio has a good sized impact on concrete sulfate assault.

- Under the identical drying–wetting cycle duration, because the dry–moist ratio will increase, the diploma of degradation of concrete with the aid of using sulfate assault will increase first after which decreases. When the dry–moist ratio is 5:1, the deterioration is the maximum serious.

Q4) Explain factor affecting compressive strength.

A4)

- Concrete energy is suffering from many factors, inclusive of excellent of uncooked materials, water/cement ratio, coarse/exceptional mixture ratio, age of concrete, compaction of concrete, temperature, relative humidity and curing of concrete.

- Quality of Raw Materials Cement: Provided the cement conforms with the right preferred and it's been saved correctly (i.e. in dry conditions), it must be appropriate to be used in concrete.

- Aggregates: Quality of aggregates, its size, shape, texture, energy and so forth determines the energy of concrete. The presence of salts (chlorides and sulphates), silt and clay additionally reduces the energy of concrete. Water: often the best of the water is blanketed with the aid of using a clause stating “..the water must be match for drinking..”. This criterion aleven though isn't always absolute and reference must be made to respective codes for checking out of water production purpose.

- Aggregate / Cement Ratio: Following factors should be stated for combination cement ratio: If the extent stays the equal and the share of cement in terms of that of sand is improved the floor place of the strong will growth. If the floor place of the solids has improved, the water call for will live the equal for the consistent workability. Assuming a growth in cement content material for no growth in water call for, the water cement ratio will decrease. If the water cement ratio reduces, the power of the concrete will growth.

- Coarse / quality combination ratio: Following factors need to be mentioned for coarse/quality combination ratio: If the percentage of fines is accelerated on the subject of the coarse combination, the general combination floor region will increase. If the floor region of the combination has accelerated, the water call for will even increase. Assuming the water call for has accelerated, the water cement ratio will increase. Since the water cement ratio has accelerated, the compressive electricity will decrease.

Q5) Define w/c ratio.

A5)

- Water / Cement Ratio The better the water/cement ratio, the more the preliminary spacing among the cement grains and the more the quantity of residual voids now no longer stuffed with the aid of using hydration products. There is one aspect lacking at the graph.

- For a given cement content, the workability of the concrete is decreased if the water/cement ratio is decreased. A decrease water cement ratio manner much less water, or extra cement and decrease workability. However if the workability turns into too low the concrete turns into tough to compact and the power reduces.

- For a given set of substances and surroundings conditions, the power at any age relies upon handiest at the water-cement ratio, presenting complete compaction may be achieved.

Q6) Explain type of cement.

A6)

- Types of Cement: The distinctive varieties of cement come from including numerous elements and converting the proportions of elements. These additions and modifications permit cement for use in the whole lot from preferred creation paintings to sulfate-resistant packages like sewage systems.

- Portland cement is handiest one in all 5 simple varieties of cement diagnosed through ASTM, the overall listing consists of: Type 1 is regular Portland cement (OPC), that is a preferred-use material.

- Type 2 has slight sulfate resistance, and its MH version is fairly proof against warmth of hydration. It’s utilized in systems so one can come into touch with sulfate in water or soil.

- Type three cement is an additional fast hardening cement. Most concrete takes approximately a month to get to its complete power after it's far poured; this cement turns into tougher greater quickly.

- Type four is a low warmth cement that radiates much less warm temperature because it units and dries. It’s used for packages in which an excessive amount of warmth is undesirable.

- Type five cement is particularly sulfate resistant, used for touch with excessive alkaline soil and water. Other cement sorts you can run into include: Types 1A, 2A, and 3A, which might be editions of kind 1, 2, and three cements.

- These varieties of cement have air-entraining substances jumbled in to lead them to proof against moisture damage. Types IL (Portland-limestone), IS (Portland-slag cement), IT (ternary blended), and IP (Portland pozzolana) cement, which might be hydraulic and feature unique properties.

- IS cement, usually referred to as slag cement, consists of granulated blast furnace slag and is frequently used to update a part of the portland cement going into the concrete. Type GU, HE, MS, HS, MH, and LH cements, whose names talk to their properties. GU stands for preferred use, HE for excessive early power, and MS and HS for slight and excessive sulfate resistance. Similarly, MH and LH talk to cement sorts with slight and excessive warmth of hydration.

Q7) What is air entrainment?

A7)

- Air entrainment in concrete is the intentional introduction of tiny air bubbles in a batch with the aid of using including an air entraining agent at some point of mixing. A shape of surfactant (a floor-energetic substance that during the example reduces the floor anxiety among water and solids) it lets in bubbles of a favored length to shape.

- These are created at some point of concrete mixing (at the same time as the slurry is in its liquid state), with maximum surviving to stay a part of it whilst hardened.

- Though hardened concrete seems as a compact solid, it's miles in reality surprisingly porous (regular concrete porosity: ~ 6 – 12 vol.%), having small capillaries because of the evaporation of water past that required for the hydration reaction.

- A water to cement ratio (w/c) of about 0.38 (this indicates 38 lbs. Of water for each one hundred lbs. Of cement) is needed for all of the cement debris to hydrate.

- Water past this is surplus and is used to make the plastic concrete greater viable or effortlessly flowing or much less viscous. To gain a appropriate stoop to be viable, maximum concrete has a w/c of 0.forty five to 0.60 on the time of placement, because of this that there may be large extra water so as to now no longer react with cement.

- When the extra water evaporates it leaves little pores in its place. Environmental water can later fill those voids thru capillary action. During freeze-thaw cycles, the water occupying the ones pores expands and creates tensile stresses which result in tiny cracks.

- These cracks permit greater water into the concrete and the cracks enlarge. Eventually the concrete spalls – chunks spoil off. The failure of bolstered concrete is most customarily because of this cycle, that's extended via way of means of moisture attaining the reinforcing steel, inflicting it to rust, expand, create greater cracks, permit in greater water, and worsen the decomposition cycle.

Q8) Explain aggregates in detail.

A8)

- Aggregates are inert granular substances inclusive of sand, gravel, or overwhelmed stone that, along side water and portland cement, are an critical component in concrete.

- For a very good concrete mix, aggregates want to be clean, hard, robust debris freed from absorbed chemical compounds or coatings of clay and different exceptional substances that would purpose the deterioration of concrete.

- Aggregates, which account for 60 to seventy five percentage of the overall extent of concrete, are divided into wonderful categories--exceptional and coarse. Fine aggregates typically encompass herbal sand or overwhelmed stone with maximum debris passing via a 3/eight-inch sieve. Coarse aggregates are any debris more than 0.19 inch, however typically variety among 3/eight and 1.five inches in diameter. Gravels represent the bulk of coarse mixture utilized in concrete with overwhelmed stone making up maximum of the remainder.

- Natural gravel and sand are commonly dug or dredged from a pit, river, lake, or seabed. Crushed mixture is produced through crushing quarry rock, boulders, cobbles, or large-length gravel. Recycled concrete is a feasible supply of mixture and has been satisfactorily utilized in granular subbases, soil-cement, and in new concrete.

- After harvesting, mixture is processed: overwhelmed, screened, and washed to gain right cleanliness and gradation. If necessary, a benefaction procedure inclusive of jigging or heavy media separation may be used to improve the quality. Once processed, the aggregates are dealt with and saved to reduce segregation and degradation and save you contamination.

- Aggregates strongly affect concrete's freshly combined and hardened residences, aggregate proportions, and economy. Consequently, choice of aggregates is a crucial procedure.

- Although a few version in mixture residences is expected, traits which can be taken into consideration include: grading durability particle form and floor texture abrasion and skid resistance unit weights and voids absorption and floor moisture

Q9) What is mixing water?

A9)

- The key to attaining a strong, long lasting concrete rests withinside the cautious proportioning and combining of the ingredients.

- A combination that doesn't have sufficient paste to fill all of the voids among the aggregates could be hard to area and could produce hard surfaces and porous concrete. A combination with an extra of cement paste could be clean to area and could produce a clean surface; however, the ensuing concrete isn't cost-powerful and may extra without problems crack. Portland cement's chemistry involves lifestyles withinside the presence of water. Cement and water shape a paste that coats every particle of stone and sand—the aggregates.

- Through a chemical response known as hydration, the cement paste hardens and profits energy. The exceptional of the paste determines the man or woman of the concrete. The energy of the paste, in turn, relies upon at the ratio of water to cement.

- The water-cement ratio is the load of the combination water divided through the load of the cement. High-exceptional concrete is produced through reducing the water-cement ratio as an awful lot as feasible with out sacrificing the workability of clean concrete, permitting it to be well placed, consolidated, and cured.

- A well designed combination possesses the preferred workability for the clean concrete and the specified sturdiness and energy for the hardened concrete. Typically, a combination is set 10 to fifteen percentage cement, 60 to seventy five percentage combination and 15 to twenty percentage water. Entrained air in lots of concrete mixes may additionally absorb any other five to eight percentage.

Q10) Define admixtures.

A10)

- Concrete, the unmarried maximum widely-used constructing cloth withinside the world, has a records courting again to the Romans and historic Egyptians. Given that concrete is used two times as a good deal in creation over all different constructing materials, emphasis on quality, overall performance and sustainability is critical for the enterprise to develop and thrive.

- One of the maximum vital elements in excessive overall performance, long-lasting, long lasting and delightful concrete produced these days are concrete admixtures. Concrete admixtures are herbal or synthetic chemical compounds or components brought for the duration of concrete blending to decorate unique houses of the clean or hardened concrete, which include workability, durability, or early and very last strength.

- The first step in optimizing concrete is to recognize that concrete is no longer simply cementitious materials, aggregates and water. It is a high performance material with not just four, but seven essentials – consisting of water, cementitious material, sand, gravel, chemical admixtures, additives and fiber reinforcement.

Q11) What is curing conditions?

A11)

- Curing performs a critical function on power improvement and sturdiness of concrete. Curing takes location straight away after concrete setting and finishing, and includes renovation of preferred moisture and temperature conditions, each at intensity and close to the surface, for prolonged durations of time.

- Properly cured concrete has a good enough quantity of moisture for endured hydration and improvement of power, quantity stability, resistance to freezing and thawing, and abrasion and scaling resistance. The duration of good enough curing time is depending on the subsequent factors: Mixture proportions Specified power Size and form of concrete member Ambient climate conditions Future publicity conditions

- Slabs on ground (e.g. Pavements, sidewalks, parking lots, driveways, floors, canal linings) and structural concrete (e.g. Bridge decks, piers, columns, beams, slabs, small footings, cast-in-vicinity walls, keeping walls) require a minimal curing duration of 7 days for ambient temperatures above forty levels Fahrenheit1.

- American Concrete Institute (ACI) Committee 301 recommends a minimal curing duration similar to concrete accomplishing 70 percentage of the desired compressive strength2. The frequently unique seven-day curing typically corresponds to about 70 percentage of the desired compressive strengths.

- The 70 percentage energy stage may be reached faster whilst concrete remedies at better temperatures or whilst sure cement/admixture combos are used. Similarly, longer time can be wished for unique cloth combos and/or decrease curing temperatures. For this reason, ACI Committee 308 recommends the subsequent minimal curing periods

Q12) Explain tensile and flexural strength of concrete.

A12)

Tensile Strength Of Concrete

- The tensile electricity of concrete is its potential to face up to cracking or breaking beneathneath anxiety. Although concrete is not often loaded beneathneath natural stress in a shape, f

- Iguring out the tensile electricity is vital to apprehend the volume of the viable damage. Breaking and cracking get up whilst tensile forces surpass the tensile electricity. Compared to the ultra-excessive overall performance concrete, conventional concrete has noticeably excessive compressive electricity as compared to tensile electricity, that is notably lower. This shows that any concrete shape which can go through tensile pressure have to first be strengthened with excessive tensile electricity substances like steel. The expertise approximately the tensile electricity of concrete is an increasing number of getting massive because of its importance in coping with ability cracking.

- However, trying out the tensile electricity of concrete is relatively tricky – in fact, there's no area take a look at for direct judgment. But, oblique strategies like splitting are pretty helpful. Studies imply that conventional concrete’s tensile electricity varies among three hundred and seven hundred psi, i.e., round 2 to five MPa. This means, on average, the anxiety averages approximately 10% of the compressive electricity.

Flexural Strength Of Concrete

- Flexural energy establishes the capacity of concrete to resist bending. It is an oblique degree of tensile energy. Let us apprehend flexure energy with this conventional example – numerous structures, consisting of pavements, slabs, and beams, and its additives are difficulty to bending or flexure.

- Talking of a beam, it could be loaded on the middle and be supported on the ends. Its backside fibers are in tension, while higher ones are in compression. If this beam is built with concrete, it's going to revel in a tensile failure withinside the decrease fibers due to the fact concrete has a weaker tension. However, consisting of some metal bars withinside the decrease place will maintain a greater full-size load because the reinforcing metal has excessive tensile energy.

- In fact, if the reinforcing metal is pre-careworn in concrete, the beam will nevertheless be strong.

- The flexural energy of concrete is typically decided via way of means of trying out a easy beam in which the focused load is implemented at every of the 1/3 points. The numbers are then expressed in a Modulus of Rupture (MR) in psi. Depending at the unique concrete mix, flexural energy is preferably everywhere among 10% and 15% of the compressive energy.

Q13) Explain relation between cracking in compression.

A13)

- Concrete is the maximum not unusualplace constructing cloth across the world. Since the discovery of contemporary-day cement with the aid of using Louis Vicat in 1817, studies and improvement efforts have progressed its properties: packages were progressed, mechanical energy and chemical concrete-crack-bodyresistance were expanded and new substances consisting of pre-confused concrete were developed.

- Has concrete grow to be best over the years? Looking cautiously at the numerous concrete systems that surround us, even along with the maximum current buildings, we see that now no longer any such systems is flawlessly intact. This highlights the unavoidable weak point of concrete: its tendency to crack.

- Cracking is exacerbated with the aid of using the thing which made concrete so popular: its compatibility with steel, and the cappotential of strengthened concrete to satisfy the necessities for a sophisticated constructing cloth.

- However, are cracks all of the same? Certainly now no longer! In fact, cracks may be because of numerous various factors consisting of deformation, hydraulic shrinkage, thermal shrinkage or swelling.

Q14) What is impact strength?

A14)

Impact strength

- Predicting the effect resistance of concrete and bolstered concrete systems has been of hobby for lots years. Constitutive fashions that account for stress price consequences, excessive pressure, and the related dynamic electricity growth are the important thing to a success predictions.

- Constitutive fashions accounting for stress price consequences may be labeled into harm fashions, plasticity fashions, and harm-plasticity fashions. Damage fashions for concrete accounting for excessive stress prices have been evolved, for instance.

- A famous plasticity version for concrete became proposed by as an extension of the Johnson-Cook version in the beginning evolved for metals. In this version, the dynamic electricity growth became associated with the modern-day stress price.

- However, reminiscence consequences have been now no longer accounted for. Furthermore, discontinuities withinside the stress-stress reaction is allowed which might be bodily now no longer meaningful. In, the dynamic buckling electricity became consequently depending on the stress price records and a mean stress price.

- A viscous harm-plasticity version accounting for excessive stress prices and excessive pressures became proposed by. Therefore, a dynamic harm variable became added that decayed the static harm evolution. The decaying feature relies upon on preceding harm-prices or harm increments. The scalar harm became in a while prolonged to a harm tensor accounting for the anisotropy for concrete below tensile loading at the same time as a scalar harm became maintained in compression.

Q15) What is fatigue strength?

A15)

- For many structural engineers, the problem of fatigue evaluation has been restrained to three simplified opinions primarily based totally at the American Institute of Steel Construction (AISC) Steel Construction Manual that asserts much less than 2,000,000 cycles implies no problem.

- For concrete structures, the presumption of any fatigue loss changed into by no means even a layout attention in normal coursework or practice.

- Therefore, expert structural engineers withinside the U.S. Have by no means definitely been educated in know-how the consequences of fatigue and fracture mechanics, besides Northridge Earthquake’s effect on welded metallic second body connections. T

- The commercial age (1920 to 1960) noticed a proliferation of latest buildings, bridges, and infrastructure factors constructed below this methodology. As the career maintains to conform into greater esoteric, analytical, and targeted areas, structural engineers understand that the problem of fatigue is greater than only a textbook dialogue and has very actual implications at the long time issues of structures. Structures are actually passing 50 years. S

- Ome have nicely over a hundred years of provider existence and are starting to expose intense symptoms and symptoms of long-time period put on and tear. This is specially genuine of bridges of each metallic and urban in which cracking, corrosion, and fractures are proscribing the prolonged existence of those important arteries of our economy.

- Why is fatigue evaluation important? Here are the essential reasons: Fatigue loading ends in fractures, cracking, and eventual collapse/failure due to the fact the shape will probable fail earlier than it reaches its yield point. Even aleven though the shape is elastic, it nevertheless poses a existence-protection risk to occupants.

- Designing for energy, ductility, dynamic response, stress compatibility, and serviceability are essential however haven't any correlation to fatigue evaluation. A shape may be compliant with all the simple tenets of structural layout and nevertheless fail in fatigue.

- Increasing the energy (i.e. yield energy/stiffness) does now no longer always make a contribution to higher fatigue energy. Fatigue failure is the end result of a excessive quantity of cycles with low to mild pressure over an prolonged duration that finally fractures the cloth and reasons failure.

- These fractures will develop and in the long run undermine the structural energy of the member and the system.