Unit - 4

Mix Design

Q1) Explain mix Design – Process.

A1)

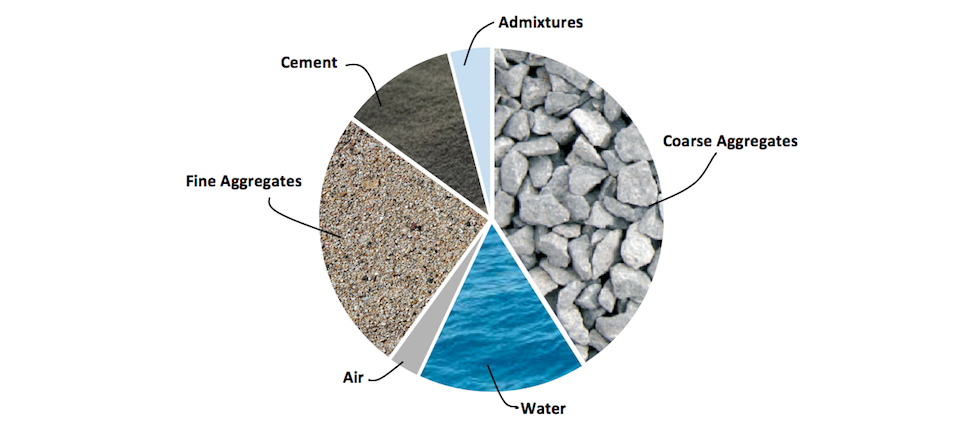

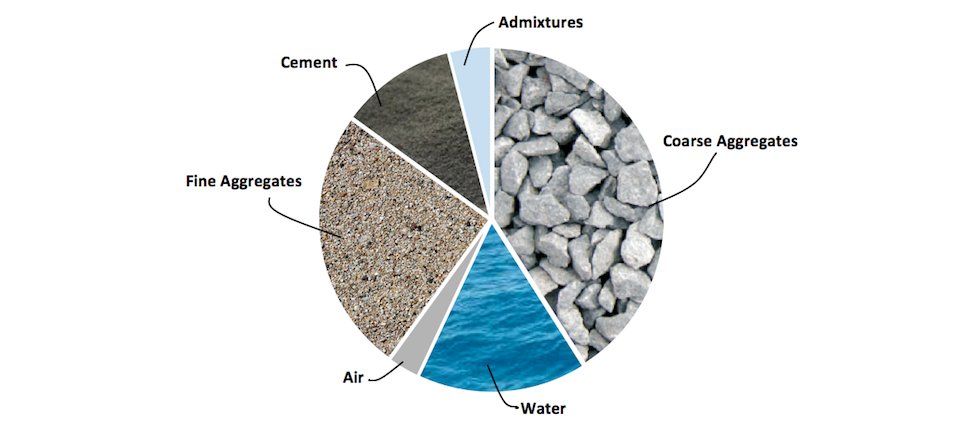

- A concrete blend is a aggregate of 5 fundamental factors in diverse proportions: cement, water, coarse aggregates, high-quality aggregates (i.e. sand), and air.

- Additional factors along with pozzolanic substances and chemical admixtures also can be included into the combinationture to present it positive acceptable properties.

- While a concrete blend layout is a procedure of choosing components for a concrete aggregate and choosing their proportions. When designing a blend, you have to constantly do not forget the preferred strength, durability, and workability of the concrete for the assignment in question.

- Concrete blend layout is regularly mistakenly noted as “cement blend layout.” However, cement is clearly one of the elements of concrete. It is a binding substance that lets in concrete to set, harden, and cling to different materials. Therefore, it can't and must now no longer be used interchangeably with concrete blend layout.

Fig 1: Mix design

- Calculating Concrete Mixes Giatec’s loose Concrete Hub app now functions a brand new blend device that lets in you to layout your concrete aggregate quick and easily. No want to have the ACI widespread on hand--the utility affords all pointers and plays all calculations for you.

- How to Design a Concrete Mix In general, concrete mixes need to comply with the guidelines (ACI Committee, 2009). A concrete blend may be designed the usage of the tables and calculations furnished withinside the standard. All concrete mixes own particular properties, the layout method may be time-ingesting and challenging. The Concrete Hub app, however, solves those demanding situations related to growing a completely unique concrete blend.

Q2) What is characteristic strength?

A2)

Characteristic strength

- Characteristic energy is described as that stage of energy under which a detailed share of all legitimate check consequences is anticipated to fail. Unless in any other case stated, this share is taken to be 5%.

- Due to the variety of constituent substances and testing, the concrete should be designed to fulfill a goal suggest energy, i.e. a margin above the feature energy is needed to offer a 95% self belief in attaining the feature.

- The margin is primarily based totally on 1.sixty four well known deviations (sd). Typical manufacturing sd for concrete can be 6MPa however properly managed manufacturing may be a whole lot lower.

- The feature energy is primarily based totally at the statistical evaluation of the take a look at consequences due to the fact there are versions withinside the energy of the fabric used.

- In order to simplify the evaluation, it could be assumed that the version in energy follows a regular distribution curve that's symmetric approximately the suggest fee as proven beneath in Fig

Fig 2: Characteristic strength

Therefore, characteristic strength = Mean strength – k S

Where S is the standard deviation, k=1.64, corresponding to 5% probability

Q3) What is variance?

A3)

- Is the version withinside the compressive electricity of concrete throughout the thickness of horizontally forged factors negligibly small or alternatively desires to be taken into consideration on the layout stage? There are conflicting solutions to this question.

- In order to decide if the compressive electricity of concrete varies throughout the thickness of horizontally forged factors, ultrasonic exams and negative exams had been finished on center samples taken from a 350 mm thick slab made of sophistication C25/30 concrete

- . Special point-touch probes had been used to degree the time taken for the longitudinal ultrasonic wave to byskip via the examined sample. The correlation among the rate of the longitudinal ultrasonic wave and the compressive electricity of the concrete withinside the slab became decided. The shape of the concrete throughout the thickness of the slab became evaluated the use of GIMP 2.10.4.

- It became determined that the destructively decided compressive electricity numerous handiest slightly (with the aid of using 3%) throughout the thickness of the located layer of concrete.

- Whereas the averaged ultrasonically decided electricity of the concrete withinside the equal samples does now no longer range throughout the thickness of the analyzed slab. Therefore, it became concluded that the mild growth in concrete compressive electricity with intensity under the pinnacle floor is a herbal factor and want now no longer be taken into consideration withinside the evaluation of the electricity of concrete withinside the shape.

Q4) Explain standard deviation.

A4)

- Standard deviation for concrete is the approach to decide the reliability among the compressive electricity consequences of a concrete batch.

- The popular deviation serves as the idea for manage of variability withinside the check consequences of concrete for the identical batch of concrete.

- It is a statistical approach this is primarily based totally at the correlation evaluation, checking out of hypothesis, evaluation of variance, and regression evaluation to evaluate or greater collection of compressive electricity of concrete regarding their variability.

- In easy words, the same old deviation manifests the variety of dispersion or variant withinside the end result that exists from the mean, average, or predicted value.

Assumed Standard Deviation

Sl.No | Grade of Concrete | Characteristic compressive strength (N/mm2) | Assumed standard deviation (N/mm2) |

1 | M10 | 10 | 3.5 |

2 | M15 | 15 |

|

3 | M20 | 20 | 4 |

4 | M25 | 25 |

|

5 | M30 | 30 | 6 |

6 | M35 | 35 |

|

7 | M40 | 40 |

|

8 | M45 | 45 |

|

9 | M50 | 50 |

|

10 | M55 | 55 |

|

Q5) Explain factor affection mix properties.

A5)

1. Compressive energy:

It is one of the maximum essential houses of concrete and impacts many different describable houses of the hardened concrete. The imply compressive energy required at a selected age, normally 28 days, determines the nominal water-cement ratio of the mix. The different element affecting the energy of concrete at a given age and cured at a prescribed temperature is the diploma of compaction. According to Abraham’s regulation the energy of absolutely compacted concrete is inversely proportional to the water-cement ratio.

2. Workability

The diploma of workability required relies upon on 3 factors. These are the scale of the segment to be concreted, the quantity of reinforcement, and the approach of compaction to be used. For the slender and complex segment with severa corners or inaccessible parts, the concrete should have a excessive workability in order that complete compaction may be performed with an affordable quantity of effort. This additionally applies to the embedded metal sections. The favored workability relies upon at the compacting system to be had on the site.

3. Durability

The sturdiness of concrete is its resistance to the competitive environmental situations. High electricity concrete is usually greater long lasting than low electricity concrete. In the conditions whilst the excessive electricity isn't vital however the situations of publicity are such that excessive sturdiness is vital, the sturdiness requirement will decide the water-cement ratio to be used.

4. Maximum nominal length of aggregate

In general, large the most length of aggregate, smaller is the cement requirement for a specific water-cement ratio, due to the fact the workability of concrete will increase with growth in most length of the aggregate. However, the compressive electricity has a tendency to growth with the lower in length of aggregate.

Q6) What is grading of aggregate?

A6)

- The grading of a combination may be measured through what share of the combination, through mass, passes thru extraordinary sized sieves. The grading of a combination may be altered through mixing more than one aggregates of various gradings.

- For coarse combination the subsequent statements are true: A smaller combination length calls for a bigger quantity of paste due to the fact there may be extra floor vicinity to cowl in step with extent of combination.

- A decrease extent of paste may be used even as nonetheless accomplishing the equal compressive energy if the most combination length is increased. There is a restriction for the discount of paste extent through growing most combination length, relying on the desired energy of the concrete. If the concrete is needed to be stronger, the maximum cost effective most particle length can be smaller.

- For great combination, the subsequent statements are true: If the great combination is just too coarse, harshness, bleeding and segregation might also additionally occur. If the great combination is just too great, the combinationture would require extra water and segregation might also additionally occur.

- If the grading varies significantly, the workability of the clean concrete will probably go through as a result.

Q7) Explain aggregate/ cement ration.

A7)

- In its most effective shape, concrete is a aggregate of paste and aggregates, or rocks. The paste, composed of portland cement and water, coats the floor of the fine (small) and coarse (larger) aggregates.

- Through a chemical response known as hydration, the paste hardens and profits power to shape the rock-like mass referred to as concrete.

- Within this system lies the important thing to a exquisite trait of concrete: it is plastic and malleable whilst newly mixed, sturdy and sturdy whilst hardened.

- These features give an explanation for why one material, concrete, can construct skyscrapers, bridges, sidewalks and superhighways, homes and dams.

- Proportioning: The key to accomplishing a sturdy, long lasting concrete rests withinside the cautious proportioning and combining of the ingredients. A aggregate that doesn't have sufficient paste to fill all of the voids among the aggregates could be tough to location and could produce tough surfaces and porous concrete.

- A aggregate with an extra of cement paste could be clean to location and could produce a clean floor; however, the ensuing concrete isn't cost-powerful and may extra without problems crack. Portland cement's chemistry involves lifestyles withinside the presence of water.

- Cement and water shape a paste that coats every particle of stone and sand—the aggregates. Through a chemical response known as hydration, the cement paste hardens and profits power.

- The best of the paste determines the man or woman of the concrete. The power of the paste, in turn, relies upon at the ratio of water to cement. The water-cement ratio is the load of the integration water divided via way of means of the load of the cement.

- High-best concrete is produced via way of means of reducing the water-cement ratio as a great deal as viable without sacrificing the workability of clean concrete, permitting it to be nicely placed, consolidated, and cured.

- A nicely designed aggregate possesses the preferred workability for the clean concrete and the specified sturdiness and power for the hardened concrete. Typically, a mixture is ready 10 to fifteen percentage cement, 60 to seventy five percentage combination and 15 to twenty percentage water. Entrained air in lots of concrete mixes might also take in any other five to eight percentage.

- Other Ingredients Almost any herbal water this is drinkable and has no suggested flavor or smell can be used as blending water for concrete. Excessive impurities in blending water now no longer simplest may also have an effect on placing time and urban power, however also can motive efflorescence, staining, corrosion of reinforcement, extent instability, and decreased sturdiness.

- Concrete aggregate specs normally set limits on chlorides, sulfates, alkalis, and solids in blending water except assessments may be achieved to decide the impact the impurity has at the very last concrete. Although maximum consuming water is appropriate for blending concrete, aggregates are selected carefully.

- Aggregates incorporate 60 to seventy five percentage of the overall extent of concrete. The kind and length of combination used relies upon at the thickness and reason of the very last concrete product Relatively skinny constructing sections name for small coarse combination, aleven though aggregates up to 6 inches in diameter were utilized in big dams.

- A non-stop gradation of particle sizes is appropriate for green use of the paste. In addition, aggregates have to be easy and loose from any depend that could have an effect on the best of the concrete.

Q8) What is degree of quality control?

A8)

- To meet or exceed nice requirements, companies should always look at and alter their processes, merchandise and services.

- This exercise is called nice warranty (QA), and it performs a important function in how companies produce merchandise and supply services. In Ontario university nice warranty and nice manipulate packages, you may benefit the talents you want to create and enforce nice regulations and objectives. If you need to use your systematic questioning to a profession in nice warranty, here’s what you want to know.

- Quality Assurance and Quality Control Courses Quality warranty packages at Ontario faculties train college students the strategies and practices had to make sure positive tiers of nice and additionally to assist growth consumer satisfaction, commercial enterprise performance and average profit.

- Courses will cognizance on: Including QA in commercial enterprise plans and strategies Performing a lot of nice audits Following worldwide requirements of nice Managing relationships with clients and suppliers Identifying the fee of nice Students will discover ways to layout checks and interpret outcomes to benefit treasured statistics approximately a commercial enterprise’s processes, merchandise and services.

- Many nice warranty packages additionally provide co-op paintings phrases or discipline placements, in which college students will follow what they’ve found out in one in every of many industries the use of QA.

- General Quality Assurance and Quality Control Program Requirements Most nice warranty and nice manipulate packages require a post-secondary diploma or diploma, and / or good sized applicable paintings enjoy withinside the discipline.

Q9) Explain design mix by Road note no. 4 (BS). IS: 10262: 2009.

A9)

- This Indian Standard (Second Revision) turned into followed via way of means of the Bureau of Indian Standards, after the draft finalized via way of means of the Cement and Concrete Sectional Committee have been authorized via way of means of the Civil Engineering Division Council.

- This well known gives recommendations for proportioning concrete mixes as consistent with the necessities the use of the concrete making substances such as different supplementary substances diagnosed for this purpose.

- This well known turned into first posted in 1982 and eventually revised in 2009. In the primary revision, the identify of the well known turned into changed as ‘Concrete blend proportioning — Guidelines’ from ‘Recommended recommendations for concrete blend layout’.

- The principal modifications withinside the first revision have been, proscribing the applicability of the same old to normal and well known grades of concrete, aligning the same old to IS 456 : 2000 ‘Plain and strengthened concrete — Code of practice (fourth revision)’; evaluation and amendment of the necessities for choice of water cement ratio, water content material and estimation of coarse mixture content material and quality mixture content material; inclusion of an additional illustrative instance of concrete blend layout, etc.

- In this 2nd revision, the subsequent principal adjustments were made:

a) The well known has been divided into 5 sections, as follows: 1) Section 1 General 2) Section 2 Ordinary and well known grades of concrete three) Section three High electricity grades of concrete four) Section four Self compacting concrete five) Section five Mass concrete

b) Mix proportioning manner for excessive electricity concrete for M sixty five or above (as much as goal electricity of M 100) has been included.

c) The preliminary information to be furnished for blend proportioning has been made extra encompassing, masking the provisions of revised IS 383: 2016 ‘Coarse and quality aggregates for concrete (1/3 revision)’, use of admixtures, etc.

d) The goal imply electricity for blend proportioning formulation has been delicate to encompass a brand new issue based at the grade of concrete. This has been accomplished to make sure a minimal margin among the characteristic compressive electricity and the goal implies compressive electricity.

e) The calculations for well known deviation were detailed.

f) A graph of water-cement ratio as opposed to 28 days electricity of concrete has been brought for different grades and kinds of cement, as a trade approach for assuming the preliminary water-cement ratio.

g) Illustrative annexes for concrete blend proportioning for PPC, OPC with fly ash, OPC with ggbs, excessive electricity concrete, self compacting concrete and mass concrete were furnished.

h) Guidelines on the use of/choosing water decreasing admixtures were brought as an informatory annex (see Annex G).

j) The attention of air content material in layout of normal (non-air entrained) concrete blend proportion, has been reintroduced.

Q10) Write a note on additives and admixtures.

A10)

- Over the beyond few years, the development enterprise has skilled terrific boom and improvement. This has necessitated the improvement of present day admixtures and components.

- Additives and admixtures for concrete are chemical materials delivered to concrete to enhance its bodily and chemical properties.

- These additives constitute a big selection of merchandise with various chemical properties. The most important distinction among admixtures and components is the levels at which the materials are delivered to concrete or cement. Additives are delivered withinside the cement production process, at the same time as the addition of admixtures is accomplished whilst making concrete mixtures.

- What Are Additives? Additives are delivered to cement at some stage in production to enhance its houses.

- Typically, the uncooked substances concerned in cement manufacture encompass alumina, lime, iron oxide, and silica. After mixing, the substances are heated to approximately 1500℃ to permit the cement to reap its very last chemical houses.

- What Are Admixtures? Admixtures for concrete may be of types, natural and inorganic compounds. Multifunctional admixtures are people who regulate multiple bodily or chemical houses of the concrete mixture. There is a extensive sort of admixtures to be had for enhancing specific elements of concrete. Admixtures may be labeled into:

- Concrete components and admixtures are presently the exceptional acting product class of production chemicals.

- At Bisley, we paintings with neighborhood and multinational admixture organizations to make sure that our customers get the exceptional merchandise for his or her production activities. Visit our internet site to view and buy the simplest and relied on concrete components and urban admixtures globally.

Q11) Explain types of admixtures.

A11)

- Water Reducing Admixtures: These are compounds that characteristic as plasticizers, which lessen the water content material of a concrete blend through as plenty as 5% without converting its consistency. Water decreasing admixtures are normally polycyclic derivatives or phosphates. When brought, those admixtures growth the compressive power of a concrete blend through making it extra plastic. This form of admixture is generally used with ground and street concrete.

- High Range Water Reducers: These are superplasticizers, mainly polymer concrete admixtures that lessen water content material through as plenty as 40%. With those admixtures, the porosity of the combination is decreased, consequently enhancing its power and sturdiness. These admixtures are generally applied for self-compacting and sprayed concrete.

- Accelerating Admixtures: Concrete generally takes time to alternate from plastic to a hardened state. Polyethylene glycols, chlorides, nitrates, and steel fluorides are generally used to make those varieties of admixtures. These materials may be brought to a concrete blend to shorten the time it takes to bond and set.

- Air-Entraining Admixtures: These admixtures are used to make air-entrained concrete mixtures. They allow the incorporation of air bubbles into the concrete combination subsequently enhancing houses inclusive of sturdiness and power through changing the freeze-thaw of the cement.

- Retarding Admixtures: Unlike accelerating admixtures that shorten bonding and setting, retarding admixtures growth the time concrete takes to set. Such admixtures do now no longer alternate the water-cement ratio however use steel oxides and sugars to bodily preclude the binding process.

Q12) What is natural products-Dietomaceousearth By products?

A12)

- Products containing diatomaceous earth are maximum typically dusts. Other formulations encompass wettable powders and pressurized liquids. Currently, there are over one hundred fifty merchandise registered to be used outside and inside of buildings, farms, gardens, and puppy kennels. Some merchandise also can be used immediately on puppies and cats. Diatomaceous earth merchandise are registered to be used in opposition to mattress bugs, cockroaches, crickets, fleas, ticks, spiders, and plenty of different pests.

- There are hundreds of non-pesticide merchandise that incorporate diatomaceous earth. These encompass pores and skin care merchandise, toothpastes, foods, beverages, medicines, rubbers, paints, and water filters. The Food & Drug Administration lists diatomaceous earth as "Generally Recognized as Safe".

- "Food grade" diatomaceous earth merchandise are purified. They can be used as anticaking substances in feed, or as clarifiers for wine and beer. Always observe label commands and take steps to decrease exposure.

- If any exposures occur, make certain to observe the First Aid commands at the product label carefully. For extra remedy advice, touch the Poison Control Center at 1-800-222-1222. If you desire to speak about a pesticide problem, please name 1-800-858-7378.

Q13) What is silica fume?

A13)

- Silica fume is a derivative from the manufacturing of elemental silicon or alloys containing silicon in electric powered arc furnaces.

- At a temperature of about 2000°C the discount of high-purity quartz to silicon produces silicon dioxide vapor, which oxidizes and condenses at low temperatures to supply silica fume. Silica fume debris are spherically fashioned and really great, having a median length of 0.1–0.three µm (De Belie et al., 2017; Jiao et al., 2017; Thomas, 2013).

- In a few cases, man or woman debris can fuse collectively to shape small agglomerates which can variety from 1 to one hundred μm in length (ACI-Committee-234, 2006). The particular gravity of silica fume is 2.20–2.30 (Khan & Siddique, 2011; Tafraoui et al. 2016; Thomas, 2013).

- The floor region of silica fume debris can variety among 13,000 and 30,000 m2/kg, measured via way of means of nitrogen absorption equipment (Valipour et al. 2013). (Note that the floor region of silica fume isn't always immediately akin to that of different SCMs measured the usage of the Blaine method.)

- The great particle length of the as-produced silica fume makes it difficult to deal with, from a sensible perspective. To enhance the benefit of handling, opportunity sorts of silica fume had been used to triumph over this realistic difficulty. Some providers deal with silica fume as a water-primarily based totally slurry, and others densify and compact the silica fume, that could markedly lessen the quantity of dirt related to the great debris.

Q14) Explain rice husk ash.

A14)

- Rice husks are the difficult defensive coverings of rice grains that are separated from the grains at some stage in milling process. Rice husk is an abundantly to be had waste cloth in all rice generating countries, and it consists of approximately 30%–50% of natural carbon.

- In the direction of a normal milling process, the husks are eliminated from the uncooked grain to expose entire brown rice which upon similarly milling to do away with the bran layer will yield white rice.

- Current rice manufacturing withinside the international is anticipated to be seven hundred million tons. Rice husk constitutes approximately 20% of the burden of rice and its composition is as follows: cellulose (50%), lignin (25%–30%), silica (15%–20%), and moisture (10%–15%).

- Bulk density of rice husk is low and lies withinside the variety 90–a hundred and fifty kg/m3. Sources of rice husk ash (RHA) could be withinside the rice developing areas of the international, as as an example China, India, and the some distance-East countries. RHA is the manufactured from incineration of rice husk. Most of the evaporable additives of rice husk are slowly misplaced at some stage in burning and the number one residues are the silicates.

- The traits of the ash are established on (1) composition of the rice husks, (2) burning temperature, and (3) burning time. Every hundred kg of husks burnt in a boiler as an example will yield approximately 25 kg of RHA. In positive areas, rice husk is used as a gas for parboiling paddy in rice mills, while in a few locations it's far field-burnt as a nearby gas.

- However, the combustion of rice husks in such instances is some distance from entire and the partial burning additionally contributes to air pollution. The calorific price of rice husks is set 50% of that of coal, and assuming that husks have approximately 8%–10% of moisture content material and 0 bran, the calorific price is anticipated to be 15 MJ/kg. U

- Under managed burning conditions, the risky natural depend withinside the rice husk which includes cellulose and lignin are eliminated and the residual ash is predominantly amorphous silica

Q15) Explain admixturers-air encraining.

A15)

- Air-entraining admixtures for superior freeze-thaw sturdiness Air-entraining admixtures facilitate the improvement of a strong air-void machine inside concrete that will increase the sturdiness of the concrete.

- These admixtures impart air entrainment that consequences in: Increased resistance to deterioration from cyclic freezing and thawing Improved workability and cohesiveness of concrete placement Reduced segregation and bleeding

- Used in lots of applications, air-entrained concrete makes use of a chemical admixture (or sometimes, air-entraining cement) to provide a device of small voids at some stage in the combination method.

- These voids are stabilized through the air-entraining admixture and stay withinside the hardened concrete paste. The number one use of air-entraining concrete is for freeze-thaw resistance.

- The air voids offer stress remedy at some stage in a freeze event, permitting the water withinside the concrete to freeze without inducing massive inner stresses. Another associated use is for deicer-scaling resistance. The air voids once more offer remedy for the accumulation of salt concentrations and the pressures that end result because of attention gradients.

- Other makes use of air-entrained concrete consist of sulfate resistance, resistance to alkali-silica reactivity, and stepped forward workability. Hard troweling is a method through which a finisher makes use of a metallic trowel to densify the floor of the concrete.

- This end is elective and produces a hard, clean floor. Repeated passes of metallic troweling will bring about a burnished end, which has a mirror-like appearance. Hard-troweled surfaces aren't endorsed for outside concrete slabs, due to the fact the clean end turns into slippery while wet.

Unit - 4

Mix Design

Q1) Explain mix Design – Process.

A1)

- A concrete blend is a aggregate of 5 fundamental factors in diverse proportions: cement, water, coarse aggregates, high-quality aggregates (i.e. sand), and air.

- Additional factors along with pozzolanic substances and chemical admixtures also can be included into the combinationture to present it positive acceptable properties.

- While a concrete blend layout is a procedure of choosing components for a concrete aggregate and choosing their proportions. When designing a blend, you have to constantly do not forget the preferred strength, durability, and workability of the concrete for the assignment in question.

- Concrete blend layout is regularly mistakenly noted as “cement blend layout.” However, cement is clearly one of the elements of concrete. It is a binding substance that lets in concrete to set, harden, and cling to different materials. Therefore, it can't and must now no longer be used interchangeably with concrete blend layout.

Fig 1: Mix design

- Calculating Concrete Mixes Giatec’s loose Concrete Hub app now functions a brand new blend device that lets in you to layout your concrete aggregate quick and easily. No want to have the ACI widespread on hand--the utility affords all pointers and plays all calculations for you.

- How to Design a Concrete Mix In general, concrete mixes need to comply with the guidelines (ACI Committee, 2009). A concrete blend may be designed the usage of the tables and calculations furnished withinside the standard. All concrete mixes own particular properties, the layout method may be time-ingesting and challenging. The Concrete Hub app, however, solves those demanding situations related to growing a completely unique concrete blend.

Q2) What is characteristic strength?

A2)

Characteristic strength

- Characteristic energy is described as that stage of energy under which a detailed share of all legitimate check consequences is anticipated to fail. Unless in any other case stated, this share is taken to be 5%.

- Due to the variety of constituent substances and testing, the concrete should be designed to fulfill a goal suggest energy, i.e. a margin above the feature energy is needed to offer a 95% self belief in attaining the feature.

- The margin is primarily based totally on 1.sixty four well known deviations (sd). Typical manufacturing sd for concrete can be 6MPa however properly managed manufacturing may be a whole lot lower.

- The feature energy is primarily based totally at the statistical evaluation of the take a look at consequences due to the fact there are versions withinside the energy of the fabric used.

- In order to simplify the evaluation, it could be assumed that the version in energy follows a regular distribution curve that's symmetric approximately the suggest fee as proven beneath in Fig

Fig 2: Characteristic strength

Therefore, characteristic strength = Mean strength – k S

Where S is the standard deviation, k=1.64, corresponding to 5% probability

Q3) What is variance?

A3)

- Is the version withinside the compressive electricity of concrete throughout the thickness of horizontally forged factors negligibly small or alternatively desires to be taken into consideration on the layout stage? There are conflicting solutions to this question.

- In order to decide if the compressive electricity of concrete varies throughout the thickness of horizontally forged factors, ultrasonic exams and negative exams had been finished on center samples taken from a 350 mm thick slab made of sophistication C25/30 concrete

- . Special point-touch probes had been used to degree the time taken for the longitudinal ultrasonic wave to byskip via the examined sample. The correlation among the rate of the longitudinal ultrasonic wave and the compressive electricity of the concrete withinside the slab became decided. The shape of the concrete throughout the thickness of the slab became evaluated the use of GIMP 2.10.4.

- It became determined that the destructively decided compressive electricity numerous handiest slightly (with the aid of using 3%) throughout the thickness of the located layer of concrete.

- Whereas the averaged ultrasonically decided electricity of the concrete withinside the equal samples does now no longer range throughout the thickness of the analyzed slab. Therefore, it became concluded that the mild growth in concrete compressive electricity with intensity under the pinnacle floor is a herbal factor and want now no longer be taken into consideration withinside the evaluation of the electricity of concrete withinside the shape.

Q4) Explain standard deviation.

A4)

- Standard deviation for concrete is the approach to decide the reliability among the compressive electricity consequences of a concrete batch.

- The popular deviation serves as the idea for manage of variability withinside the check consequences of concrete for the identical batch of concrete.

- It is a statistical approach this is primarily based totally at the correlation evaluation, checking out of hypothesis, evaluation of variance, and regression evaluation to evaluate or greater collection of compressive electricity of concrete regarding their variability.

- In easy words, the same old deviation manifests the variety of dispersion or variant withinside the end result that exists from the mean, average, or predicted value.

Assumed Standard Deviation

Sl.No | Grade of Concrete | Characteristic compressive strength (N/mm2) | Assumed standard deviation (N/mm2) |

1 | M10 | 10 | 3.5 |

2 | M15 | 15 |

|

3 | M20 | 20 | 4 |

4 | M25 | 25 |

|

5 | M30 | 30 | 6 |

6 | M35 | 35 |

|

7 | M40 | 40 |

|

8 | M45 | 45 |

|

9 | M50 | 50 |

|

10 | M55 | 55 |

|

Q5) Explain factor affection mix properties.

A5)

1. Compressive energy:

It is one of the maximum essential houses of concrete and impacts many different describable houses of the hardened concrete. The imply compressive energy required at a selected age, normally 28 days, determines the nominal water-cement ratio of the mix. The different element affecting the energy of concrete at a given age and cured at a prescribed temperature is the diploma of compaction. According to Abraham’s regulation the energy of absolutely compacted concrete is inversely proportional to the water-cement ratio.

2. Workability

The diploma of workability required relies upon on 3 factors. These are the scale of the segment to be concreted, the quantity of reinforcement, and the approach of compaction to be used. For the slender and complex segment with severa corners or inaccessible parts, the concrete should have a excessive workability in order that complete compaction may be performed with an affordable quantity of effort. This additionally applies to the embedded metal sections. The favored workability relies upon at the compacting system to be had on the site.

3. Durability

The sturdiness of concrete is its resistance to the competitive environmental situations. High electricity concrete is usually greater long lasting than low electricity concrete. In the conditions whilst the excessive electricity isn't vital however the situations of publicity are such that excessive sturdiness is vital, the sturdiness requirement will decide the water-cement ratio to be used.

4. Maximum nominal length of aggregate

In general, large the most length of aggregate, smaller is the cement requirement for a specific water-cement ratio, due to the fact the workability of concrete will increase with growth in most length of the aggregate. However, the compressive electricity has a tendency to growth with the lower in length of aggregate.

Q6) What is grading of aggregate?

A6)

- The grading of a combination may be measured through what share of the combination, through mass, passes thru extraordinary sized sieves. The grading of a combination may be altered through mixing more than one aggregates of various gradings.

- For coarse combination the subsequent statements are true: A smaller combination length calls for a bigger quantity of paste due to the fact there may be extra floor vicinity to cowl in step with extent of combination.

- A decrease extent of paste may be used even as nonetheless accomplishing the equal compressive energy if the most combination length is increased. There is a restriction for the discount of paste extent through growing most combination length, relying on the desired energy of the concrete. If the concrete is needed to be stronger, the maximum cost effective most particle length can be smaller.

- For great combination, the subsequent statements are true: If the great combination is just too coarse, harshness, bleeding and segregation might also additionally occur. If the great combination is just too great, the combinationture would require extra water and segregation might also additionally occur.

- If the grading varies significantly, the workability of the clean concrete will probably go through as a result.

Q7) Explain aggregate/ cement ration.

A7)

- In its most effective shape, concrete is a aggregate of paste and aggregates, or rocks. The paste, composed of portland cement and water, coats the floor of the fine (small) and coarse (larger) aggregates.

- Through a chemical response known as hydration, the paste hardens and profits power to shape the rock-like mass referred to as concrete.

- Within this system lies the important thing to a exquisite trait of concrete: it is plastic and malleable whilst newly mixed, sturdy and sturdy whilst hardened.

- These features give an explanation for why one material, concrete, can construct skyscrapers, bridges, sidewalks and superhighways, homes and dams.

- Proportioning: The key to accomplishing a sturdy, long lasting concrete rests withinside the cautious proportioning and combining of the ingredients. A aggregate that doesn't have sufficient paste to fill all of the voids among the aggregates could be tough to location and could produce tough surfaces and porous concrete.

- A aggregate with an extra of cement paste could be clean to location and could produce a clean floor; however, the ensuing concrete isn't cost-powerful and may extra without problems crack. Portland cement's chemistry involves lifestyles withinside the presence of water.

- Cement and water shape a paste that coats every particle of stone and sand—the aggregates. Through a chemical response known as hydration, the cement paste hardens and profits power.

- The best of the paste determines the man or woman of the concrete. The power of the paste, in turn, relies upon at the ratio of water to cement. The water-cement ratio is the load of the integration water divided via way of means of the load of the cement.

- High-best concrete is produced via way of means of reducing the water-cement ratio as a great deal as viable without sacrificing the workability of clean concrete, permitting it to be nicely placed, consolidated, and cured.

- A nicely designed aggregate possesses the preferred workability for the clean concrete and the specified sturdiness and power for the hardened concrete. Typically, a mixture is ready 10 to fifteen percentage cement, 60 to seventy five percentage combination and 15 to twenty percentage water. Entrained air in lots of concrete mixes might also take in any other five to eight percentage.

- Other Ingredients Almost any herbal water this is drinkable and has no suggested flavor or smell can be used as blending water for concrete. Excessive impurities in blending water now no longer simplest may also have an effect on placing time and urban power, however also can motive efflorescence, staining, corrosion of reinforcement, extent instability, and decreased sturdiness.

- Concrete aggregate specs normally set limits on chlorides, sulfates, alkalis, and solids in blending water except assessments may be achieved to decide the impact the impurity has at the very last concrete. Although maximum consuming water is appropriate for blending concrete, aggregates are selected carefully.

- Aggregates incorporate 60 to seventy five percentage of the overall extent of concrete. The kind and length of combination used relies upon at the thickness and reason of the very last concrete product Relatively skinny constructing sections name for small coarse combination, aleven though aggregates up to 6 inches in diameter were utilized in big dams.

- A non-stop gradation of particle sizes is appropriate for green use of the paste. In addition, aggregates have to be easy and loose from any depend that could have an effect on the best of the concrete.

Q8) What is degree of quality control?

A8)

- To meet or exceed nice requirements, companies should always look at and alter their processes, merchandise and services.

- This exercise is called nice warranty (QA), and it performs a important function in how companies produce merchandise and supply services. In Ontario university nice warranty and nice manipulate packages, you may benefit the talents you want to create and enforce nice regulations and objectives. If you need to use your systematic questioning to a profession in nice warranty, here’s what you want to know.

- Quality Assurance and Quality Control Courses Quality warranty packages at Ontario faculties train college students the strategies and practices had to make sure positive tiers of nice and additionally to assist growth consumer satisfaction, commercial enterprise performance and average profit.

- Courses will cognizance on: Including QA in commercial enterprise plans and strategies Performing a lot of nice audits Following worldwide requirements of nice Managing relationships with clients and suppliers Identifying the fee of nice Students will discover ways to layout checks and interpret outcomes to benefit treasured statistics approximately a commercial enterprise’s processes, merchandise and services.

- Many nice warranty packages additionally provide co-op paintings phrases or discipline placements, in which college students will follow what they’ve found out in one in every of many industries the use of QA.

- General Quality Assurance and Quality Control Program Requirements Most nice warranty and nice manipulate packages require a post-secondary diploma or diploma, and / or good sized applicable paintings enjoy withinside the discipline.

Q9) Explain design mix by Road note no. 4 (BS). IS: 10262: 2009.

A9)

- This Indian Standard (Second Revision) turned into followed via way of means of the Bureau of Indian Standards, after the draft finalized via way of means of the Cement and Concrete Sectional Committee have been authorized via way of means of the Civil Engineering Division Council.

- This well known gives recommendations for proportioning concrete mixes as consistent with the necessities the use of the concrete making substances such as different supplementary substances diagnosed for this purpose.

- This well known turned into first posted in 1982 and eventually revised in 2009. In the primary revision, the identify of the well known turned into changed as ‘Concrete blend proportioning — Guidelines’ from ‘Recommended recommendations for concrete blend layout’.

- The principal modifications withinside the first revision have been, proscribing the applicability of the same old to normal and well known grades of concrete, aligning the same old to IS 456 : 2000 ‘Plain and strengthened concrete — Code of practice (fourth revision)’; evaluation and amendment of the necessities for choice of water cement ratio, water content material and estimation of coarse mixture content material and quality mixture content material; inclusion of an additional illustrative instance of concrete blend layout, etc.

- In this 2nd revision, the subsequent principal adjustments were made:

a) The well known has been divided into 5 sections, as follows: 1) Section 1 General 2) Section 2 Ordinary and well known grades of concrete three) Section three High electricity grades of concrete four) Section four Self compacting concrete five) Section five Mass concrete

b) Mix proportioning manner for excessive electricity concrete for M sixty five or above (as much as goal electricity of M 100) has been included.

c) The preliminary information to be furnished for blend proportioning has been made extra encompassing, masking the provisions of revised IS 383: 2016 ‘Coarse and quality aggregates for concrete (1/3 revision)’, use of admixtures, etc.

d) The goal imply electricity for blend proportioning formulation has been delicate to encompass a brand new issue based at the grade of concrete. This has been accomplished to make sure a minimal margin among the characteristic compressive electricity and the goal implies compressive electricity.

e) The calculations for well known deviation were detailed.

f) A graph of water-cement ratio as opposed to 28 days electricity of concrete has been brought for different grades and kinds of cement, as a trade approach for assuming the preliminary water-cement ratio.

g) Illustrative annexes for concrete blend proportioning for PPC, OPC with fly ash, OPC with ggbs, excessive electricity concrete, self compacting concrete and mass concrete were furnished.

h) Guidelines on the use of/choosing water decreasing admixtures were brought as an informatory annex (see Annex G).

j) The attention of air content material in layout of normal (non-air entrained) concrete blend proportion, has been reintroduced.

Q10) Write a note on additives and admixtures.

A10)

- Over the beyond few years, the development enterprise has skilled terrific boom and improvement. This has necessitated the improvement of present day admixtures and components.

- Additives and admixtures for concrete are chemical materials delivered to concrete to enhance its bodily and chemical properties.

- These additives constitute a big selection of merchandise with various chemical properties. The most important distinction among admixtures and components is the levels at which the materials are delivered to concrete or cement. Additives are delivered withinside the cement production process, at the same time as the addition of admixtures is accomplished whilst making concrete mixtures.

- What Are Additives? Additives are delivered to cement at some stage in production to enhance its houses.

- Typically, the uncooked substances concerned in cement manufacture encompass alumina, lime, iron oxide, and silica. After mixing, the substances are heated to approximately 1500℃ to permit the cement to reap its very last chemical houses.

- What Are Admixtures? Admixtures for concrete may be of types, natural and inorganic compounds. Multifunctional admixtures are people who regulate multiple bodily or chemical houses of the concrete mixture. There is a extensive sort of admixtures to be had for enhancing specific elements of concrete. Admixtures may be labeled into:

- Concrete components and admixtures are presently the exceptional acting product class of production chemicals.

- At Bisley, we paintings with neighborhood and multinational admixture organizations to make sure that our customers get the exceptional merchandise for his or her production activities. Visit our internet site to view and buy the simplest and relied on concrete components and urban admixtures globally.

Q11) Explain types of admixtures.

A11)

- Water Reducing Admixtures: These are compounds that characteristic as plasticizers, which lessen the water content material of a concrete blend through as plenty as 5% without converting its consistency. Water decreasing admixtures are normally polycyclic derivatives or phosphates. When brought, those admixtures growth the compressive power of a concrete blend through making it extra plastic. This form of admixture is generally used with ground and street concrete.

- High Range Water Reducers: These are superplasticizers, mainly polymer concrete admixtures that lessen water content material through as plenty as 40%. With those admixtures, the porosity of the combination is decreased, consequently enhancing its power and sturdiness. These admixtures are generally applied for self-compacting and sprayed concrete.

- Accelerating Admixtures: Concrete generally takes time to alternate from plastic to a hardened state. Polyethylene glycols, chlorides, nitrates, and steel fluorides are generally used to make those varieties of admixtures. These materials may be brought to a concrete blend to shorten the time it takes to bond and set.

- Air-Entraining Admixtures: These admixtures are used to make air-entrained concrete mixtures. They allow the incorporation of air bubbles into the concrete combination subsequently enhancing houses inclusive of sturdiness and power through changing the freeze-thaw of the cement.

- Retarding Admixtures: Unlike accelerating admixtures that shorten bonding and setting, retarding admixtures growth the time concrete takes to set. Such admixtures do now no longer alternate the water-cement ratio however use steel oxides and sugars to bodily preclude the binding process.

Q12) What is natural products-Dietomaceousearth By products?

A12)

- Products containing diatomaceous earth are maximum typically dusts. Other formulations encompass wettable powders and pressurized liquids. Currently, there are over one hundred fifty merchandise registered to be used outside and inside of buildings, farms, gardens, and puppy kennels. Some merchandise also can be used immediately on puppies and cats. Diatomaceous earth merchandise are registered to be used in opposition to mattress bugs, cockroaches, crickets, fleas, ticks, spiders, and plenty of different pests.

- There are hundreds of non-pesticide merchandise that incorporate diatomaceous earth. These encompass pores and skin care merchandise, toothpastes, foods, beverages, medicines, rubbers, paints, and water filters. The Food & Drug Administration lists diatomaceous earth as "Generally Recognized as Safe".

- "Food grade" diatomaceous earth merchandise are purified. They can be used as anticaking substances in feed, or as clarifiers for wine and beer. Always observe label commands and take steps to decrease exposure.

- If any exposures occur, make certain to observe the First Aid commands at the product label carefully. For extra remedy advice, touch the Poison Control Center at 1-800-222-1222. If you desire to speak about a pesticide problem, please name 1-800-858-7378.

Q13) What is silica fume?

A13)

- Silica fume is a derivative from the manufacturing of elemental silicon or alloys containing silicon in electric powered arc furnaces.

- At a temperature of about 2000°C the discount of high-purity quartz to silicon produces silicon dioxide vapor, which oxidizes and condenses at low temperatures to supply silica fume. Silica fume debris are spherically fashioned and really great, having a median length of 0.1–0.three µm (De Belie et al., 2017; Jiao et al., 2017; Thomas, 2013).

- In a few cases, man or woman debris can fuse collectively to shape small agglomerates which can variety from 1 to one hundred μm in length (ACI-Committee-234, 2006). The particular gravity of silica fume is 2.20–2.30 (Khan & Siddique, 2011; Tafraoui et al. 2016; Thomas, 2013).

- The floor region of silica fume debris can variety among 13,000 and 30,000 m2/kg, measured via way of means of nitrogen absorption equipment (Valipour et al. 2013). (Note that the floor region of silica fume isn't always immediately akin to that of different SCMs measured the usage of the Blaine method.)

- The great particle length of the as-produced silica fume makes it difficult to deal with, from a sensible perspective. To enhance the benefit of handling, opportunity sorts of silica fume had been used to triumph over this realistic difficulty. Some providers deal with silica fume as a water-primarily based totally slurry, and others densify and compact the silica fume, that could markedly lessen the quantity of dirt related to the great debris.

Q14) Explain rice husk ash.

A14)

- Rice husks are the difficult defensive coverings of rice grains that are separated from the grains at some stage in milling process. Rice husk is an abundantly to be had waste cloth in all rice generating countries, and it consists of approximately 30%–50% of natural carbon.

- In the direction of a normal milling process, the husks are eliminated from the uncooked grain to expose entire brown rice which upon similarly milling to do away with the bran layer will yield white rice.

- Current rice manufacturing withinside the international is anticipated to be seven hundred million tons. Rice husk constitutes approximately 20% of the burden of rice and its composition is as follows: cellulose (50%), lignin (25%–30%), silica (15%–20%), and moisture (10%–15%).

- Bulk density of rice husk is low and lies withinside the variety 90–a hundred and fifty kg/m3. Sources of rice husk ash (RHA) could be withinside the rice developing areas of the international, as as an example China, India, and the some distance-East countries. RHA is the manufactured from incineration of rice husk. Most of the evaporable additives of rice husk are slowly misplaced at some stage in burning and the number one residues are the silicates.

- The traits of the ash are established on (1) composition of the rice husks, (2) burning temperature, and (3) burning time. Every hundred kg of husks burnt in a boiler as an example will yield approximately 25 kg of RHA. In positive areas, rice husk is used as a gas for parboiling paddy in rice mills, while in a few locations it's far field-burnt as a nearby gas.

- However, the combustion of rice husks in such instances is some distance from entire and the partial burning additionally contributes to air pollution. The calorific price of rice husks is set 50% of that of coal, and assuming that husks have approximately 8%–10% of moisture content material and 0 bran, the calorific price is anticipated to be 15 MJ/kg. U

- Under managed burning conditions, the risky natural depend withinside the rice husk which includes cellulose and lignin are eliminated and the residual ash is predominantly amorphous silica

Q15) Explain admixturers-air encraining.

A15)

- Air-entraining admixtures for superior freeze-thaw sturdiness Air-entraining admixtures facilitate the improvement of a strong air-void machine inside concrete that will increase the sturdiness of the concrete.

- These admixtures impart air entrainment that consequences in: Increased resistance to deterioration from cyclic freezing and thawing Improved workability and cohesiveness of concrete placement Reduced segregation and bleeding

- Used in lots of applications, air-entrained concrete makes use of a chemical admixture (or sometimes, air-entraining cement) to provide a device of small voids at some stage in the combination method.

- These voids are stabilized through the air-entraining admixture and stay withinside the hardened concrete paste. The number one use of air-entraining concrete is for freeze-thaw resistance.

- The air voids offer stress remedy at some stage in a freeze event, permitting the water withinside the concrete to freeze without inducing massive inner stresses. Another associated use is for deicer-scaling resistance. The air voids once more offer remedy for the accumulation of salt concentrations and the pressures that end result because of attention gradients.

- Other makes use of air-entrained concrete consist of sulfate resistance, resistance to alkali-silica reactivity, and stepped forward workability. Hard troweling is a method through which a finisher makes use of a metallic trowel to densify the floor of the concrete.

- This end is elective and produces a hard, clean floor. Repeated passes of metallic troweling will bring about a burnished end, which has a mirror-like appearance. Hard-troweled surfaces aren't endorsed for outside concrete slabs, due to the fact the clean end turns into slippery while wet.