Unit - 4

Sedimentation

Q1) What is sedimentation?

A1)

- Sedimentation is the method of permitting debris in suspension in water to settle out of the suspension beneathneath the impact of gravity.

- The debris that settle out from the suspension turn out to be sediment, and in water remedy is referred to as sludge.

- When a thick layer of sediment keeps to settle, that is referred to as consolidation. When consolidation of sediment, or sludge, is assisted with the aid of using mechanical approach then that is referred to as thickening. In water remedy sedimentation is probably used to lessen the awareness of debris in suspension earlier than the software of coagulation, to lessen the quantity of coagulating chemical substances needed, or after coagulation and, possibly, flocculation.

- When sedimentation is carried out after coagulation, its cause is commonly to lessen the awareness of solids in suspension in order that the following filtration can feature maximum effectively.

- Sedimentation is one in every of numerous strategies for software previous to filtration: different alternatives consist of dissolved air flotation and a few strategies of filtration. Generically, such solids-liquid separation methods are every so often known as rationalization methods.

- There is quite a few strategies for making use of sedimentation and consist of: horizontal flow, radial flow, willing plate, ballasted floc and floc blanket sedimentation.

Q2) What is principle of sedimentation?

A2)

Principles

- When the awareness of debris in suspension is small, approx < 1% v/v, the debris settle with negligible effect on every different. As particle awareness will increase past approximately 1% then adjoining debris step by step affect, i.e. hinder, the behaviour of every different.

- When particle awareness exceeds approximately 8% v/v the suspension is withinside the absolutely hindered regime (see technique of awareness size below). The residences of the suspension at the moment are a characteristic of the volumetric awareness of the debris withinside the suspension, in addition to depending on different residences of the debris.

- With growing particle awareness the diploma of touch among debris step by step will increase When the particle awareness withinside the suspension is ready 18% v/v then there's a transition in how the suspension appears. For concentrations more than approximately 18% v/v, the higher interface among the water and suspension need to be distinct. For concentrations much less than approximately 18%, the interface is diffuse, more and more more so with smaller concentrations.

- When the particle awareness is ready 26% v/v adjoining debris grow to be in everlasting touch with every different such that the suspension enters the thickening regime. Hindered settling in water remedy exploits suspensions with concentrations among approximately 12 and 22% v/v. A suspension on this variety is referred to as a floc blanket, that is honestly a fluidised bed. Method of particle quantity awareness: In water remedy the debris, flocs, produced with the aid of using coagulation are quite simply deformed.

- Therefore size of volumetric awareness needs to be a compromise. A technique used for greater than forty years is to accumulate a pattern of the suspension to the pinnacle mark in a graduated cylinder, e.g. 1L, that is then left undisturbed for half-hour. The percentage of the liquid quantity occupied with the aid of using the settled debris after half-hour is taken because the particle awareness withinside the suspension.

Q3) What are types of setting basin?

A3)

Long Rectangular Settling Basin

- Long square basins are hydraulically extra stable, and glide manipulate for massive volumes is simpler with this configuration.

- A ordinary lengthy square tank have period starting from 2 to four instances their width. The backside is barely sloped to facilitate sludge scraping.

- A sluggish transferring mechanical sludge scraper constantly pulls the settled fabric right into a sludge hopper from in which it's far pumped out periodically.

- A lengthy square settling tank may be divided into 4 specific purposeful zones:

- Inlet quarter: Region wherein the glide is uniformly allotted over the pass segment such that the glide via settling quarter follows horizontal path.

- Settling quarter: Settling happens beneathneath quiescent conditions.

- Outlet quarter: Clarified effluent is accrued and discharge via outlet weir.

- Sludge quarter: For series of sludge under settling quarter.

Circular Basins

- Circular settling basins have the equal purposeful zones because the lengthy square basin, however the float regime is different. When the float enters on the middle and is baffled to float radially toward the perimeter, the horizontal pace of the water is constantly lowering as the space from the middle increases.

- Thus, the particle route in a round basin is a parabola in place of the directly line route withinside the lengthy square tank.

- Sludge elimination mechanisms in round tanks are less difficult and require much less maintenance.

Q4) What is inlet and outlet arrangement?

A4)

- Inlet devices: Inlets will be designed to distribute the water similarly and at uniform velocities. A baffle must be built throughout the basin near the inlet and must undertaking numerous ft under the water floor to expend inlet velocities and offer uniform flow;

- Outlet Devices: Outlet weirs or submerged orifices will be designed to preserve velocities appropriate for settling withinside the basin and to decrease short-circuiting. Weirs will be adjustable, and at the least equal in duration to the fringe of the tank. However, peripheral weirs aren't proper as they generally tend to reason immoderate short-circuiting.

Q5) Give simple design of sedimentation tank.

A5)

- Detention period: for plain sedimentation: 3 to 4 h, and for coagulated sedimentation: 2 to 2.5 h.

- Velocity of flow: Not greater than 30 cm/min (horizontal flow).

- Tank dimensions: L:B = 3 to 5:1. Generally L= 30 m (common) maximum 100 m. Breadth= 6 m to 10 m. Circular: Diameter not greater than 60 m. Generally 20 to 40 m.

- Depth 2.5 to 5.0 m (3 m).

- Surface Overflow Rate: For plain sedimentation 12000 to 18000 L/d/m2 tank area; for thoroughly flocculated water 24000 to 30000 L/d/m2 tank area.

- Slopes: Rectangular 1% towards inlet and circular 8%.

Q6) What is Clariflocculators?

A6)

- Clariflocculator is a aggregate of flocculation and explanation in a unmarried tank. It has concentric tanks wherein internal tank serves as a flocculation basin and the outer tank serves as a clarifier.

- In the Clariflocculator, the water enters the flocculator, wherein the flocculating paddles decorate flocculation of the feed solids. As heavy debris settle to the lowest, the liquid flows radially upward withinside the clarifier zone.

- The clarified liquid is discharged over a peripheral weir into the peripheral launder. The deposited sludge is raked to the lowest close to the principal weir from wherein it's miles routed to the sludge chamber and discharged.

Application Areas

- Municipal Water Treatment

- Primary Treatment in ETP

- Heavy Metal Removal

- Clariflocculators are used for number one/ secondary settling of raw & effluent waters. These are used for elimination of settlable suspended solids & turbidity. Different kinds of clariflocculators & clarifiers are presented to in shape utilization and placement conditions.

- Clariflocculators are broadly used for chemical number one remedy for effluent water. These Clariflocculators are designed and evolved to offer a cost-effective and quicker set up of number one remedy.

- The modern layout permits the clariflocculator to address heavy slugs even as turning in shortest floc settling time. We deliver unique sort of clariflocculators with constructed in flocculation properly and paddle kind flocculator withinside the flocculator properly which assist in growing flocks. There isn't anyt any want to present separate flocculation tank with flocculator.

Q7) Give Principle and operation of clariflocculator.

A7)

- In the Clariflocculator, the water enters the flocculator, in which the flocculating paddles decorate flocculation of the feed solids. As heavy debris settle to the bottom, the liquid flows radially upward withinside the clarifier zone,. The clarified liquid is discharged over a peripheral weir into the peripheral launder.

- Clariflocculator is a mixture of flocculation and explanation in a unmarried tank. It has concentric tanks in which internal tank serves as a flocculation basin and the outer tank serves as a clarifier. We gives settled Full/Half auxiliary Bridge cum walkway traverses over the outside distance throughout of the tank with Handrail.

- A solitary unit of Clariflocculator serves factors of each the clarifier and flocculator.It accommodates of concentric tanks - the inner tank fills in as a flocculation chamber at the same time as the outside tank fills in as a clarifier chamber.

- The dosed water is metered into the flocculation chamber in which its paddling mechanics begins offevolved flocculation of solids. The next muck and overwhelming sturdy particulates settles to the bottom below the appealing power constrain; the shops are raked to the bottom focal pocket and released.

- The commonly clean water from the flocculation chamber radially streams outward into the removal chamber for moreover preparing. Whenever achieved and labored legitimately, they are able to control the fee of fee-finances in capital ventures, carry down impression, and fee-reserve finances in forms.

Q8) What is plate and tube settlers?

A8)

- Plate and Tube Settlers had been evolved as an opportunity to shallow basins and are used along with each current and particularly designed sedimentation basins.

- Plate and Tube Settlers are shallow settling gadgets along with stacked offset trays or bundles of small plastic tubes of numerous geometries. They are used to beautify the settling traits of sedimentation basins. The shape, hydraulic radii, attitude of inclination, and duration of the plate and tube settlers will range in keeping with the unique installation.

- Normal exercise is to insert the plate or tube settlers in sedimentation basins (both square or circular) of enough depth. The go with the drift in the basin passes upward through the plate or tube modules and exits from the basin above the modules. The solids that settle out in the plates or tubes flow by gravity counter presently downward and out of the tube modules to the basin bottom. To be self-cleaning, plate or tube settlers are normally set at an attitude among 45° and 60° above the horizontal.

- When the attitude of inclination of plate or tube is extra than 60° the performance of the settling basin decreases. If the plates and tubes are willing at angles much less than 45°, settler will have a tendency to build up solids, which have to be flushed out periodically (normally with excessive strain hose). The want for flushing poses a hassle with the usage of plate and tube settlers wherein the traits of the solids to be eliminated range from day to day. Tube settlers are a mild weight shape composed of carefully spaced tubes on an incline (normally among 45° and 60°).

- Clarifier up go with the drift is exceeded through those tubes. Settling inside those tubes and phone rationalization of exceptional floc consequences in a build-up of debris at the tube surfaces. Particles integrate to shape agglomerates which grow to be heavy sufficient to slough towards the upward go with the drift and slide down the tube slope to enroll in the sludge blanket below.

Q9) What is high rate settlers and Sludge blanket clarifier?

A9)

High Rate Settlers

- High price tube settlers are designed to enhance the traits of the square basin and to growth glide through the tank. The tube settlers encompass a chain of tubes which can be hooked up at a six hundred perspective to the floor of the tank. The glide is directed up through the settlers.

- Particles will be inclined to glide at an perspective unique than the water and to touch the tube sooner or later earlier than attaining the pinnacle of the tube. After debris had been eliminated from the glide and amassed at the tubes, they have a tendency to slip down the tube and lower back into the sludge zone.

Sludge blanket clarifier

- Most up go with the drift designs are called” sludge blanket” clarifiers. After coagulation and or flocculation withinside the sludge blanket gadgets, the incoming water passes via the suspended layer of formerly shaped floc.

- The underneath Figure suggests an up go with the drift sludge blanket clarifier. Because the center-properly in those gadgets is frequently fashioned like an inverted cone, the upward thrust price of the water decreases because it rises via the gradually enlarging go section.

- When the upward thrust price, decreases sufficient to same the settling price of the suspended floc exactly, a wonderful sludge/ liquid interface forms. Sludge blanket performance relies upon at the filtering motion because the freshly coagulated or flocculated water passes via the suspended floc. Higher sludge stages boom the filtration performance.

- In practice, the pinnacle sludge interface is carried at the best secure degree to save you upsets that would bring about big quantities of floc carryover into the overflow. Excessive sludge withdrawal or blow down need to additionally be avoided. The sludge blanket degree is frequently exceedingly touchy to modifications in throughput, coagulant addition, and modifications in uncooked water chemistry and temperature.

Q10) What is filtration?

A10)

- Filtration, the manner wherein strong debris in a liquid or gaseous fluid are eliminated with the aid of using using a clear out medium that allows the fluid to by skip through however keeps the strong debris.

- Either the clarified fluid or the strong debris eliminated from the fluid can be the favored product. In a few methods used withinside the manufacturing of chemicals, each the fluid filtrate and the strong clear out out cake are recovered. Other media, which includes electricity, light, and sound, additionally may be filtered.

- The artwork of filtration become recognized to early humans, who acquired clean water from a muddy river with the aid of using scooping a hollow withinside the sand on a river financial institution to a intensity under the river water level. Clear water filtered with the aid of using the sand might trickle into the hollow. The identical manner on a bigger scale and with refinements is typically used to purify water for cities.

- The fundamental necessities for filtration are:

(1) a clear out medium;

(2) a fluid with suspended solids;

(3) a using pressure which includes a strain distinction to purpose fluid to flow; and

(4) a mechanical device (the clear out) that holds the clear out medium, incorporates the fluid, and allows the utility of pressure.

- The clear out might also additionally have unique provisions for elimination of the clear out cake or different strong debris, for laundry the cake, and in all likelihood for drying the cake.

- The diverse techniques used for treating and putting off the cake, for putting off the clarified filtrate, and for developing the using pressure at the fluid were blended in diverse approaches to provide a exquisite type of clear out equipment.

Q11) What is mechanism of filtration?

A11)

- Filtration may be described as a stable-liquid separation procedure wherein solids are separated from the suspension via way of means of passing through a porous medium that accumulates the solids however permits the passage of fluids.

- The suspension of stable and liquid that is to be filtered is called slurry. The porous medium used to clear out the answer is called a clear out medium. The accrued solids are called clear out cake. The clean liquid passing through the clear out is filtrate.

- The time period explanation is used whilst the quantity of solids in a liquid isn't always greater than 1% w/v. The price of filtration is described because the extent of filtrate amassed in unit time.

- Numerous mechanisms: It has been the filtration procedure includes recognized that straining is the principle mechanism this is operative withinside the removal of solids in suspension in the course of the filtration. Other mechanisms encompass impaction, interception, and adhesion, etc.

- Straining: The debris that are large than the pore area of the filtering medium are strained out mechanically. While debris smaller than the pore area are trapped in the clear out.

- Sedimentation: The debris in the clear out determine the filtering medium.

- Impaction: Heavy debris do now no longer observe the streamlined flow.

- Interception: The debris are eliminated in the course of touch with the floor of the clear out medium

- Adhesion: The debris adhere to the floor of the clear out medium as they pass

- Flocculation: It takes place in the interstices of the clear out medium.

- Chemical Adsorption (ie. Bonding, chemical interaction) and Physical adsorption (i.c. Electrostatic force, van der wall force): Once a particle has come into touch with the floor of the clear out medium or with different debris, this sort of mechanisms, chemical or bodily adsorption or each might also additionally occur.

- Biological boom: The organic boom withinside the clear out reduces the pore extent and improves the elimination of debris with any of the preceding elimination mechanisms

Q12) Give types of filters.

A12)

1. Depth filtration: In this technique, the elimination of suspended fabric from the liquid suspension is achieved through passing the liquid through a clear out mattress composed of a granular or compressible clear out medium. The fabric used for the clear out mattress is a packed mattress of sand, anthracite, or different granular media. Solids (particles) get connected with gradient density shape to the media through adsorption through bodily restriction. This technique is used withinside the remedy of floor waters for potable water supply.

2. Surface filtration: Surface filtration entails the elimination of fabric suspended in a liquid the usage of sieving. In this technique, the liquid passes through a skinny septum (ie, clear out fabric). Materials which have been used as a clear out septum consist of woven cord cloths, material fabric of various fabric, and a lot of artificial materials

3. Membrane Filtration: Membrane filtration is a separation manner that makes use of a semipermeable membrane.

It includes parts:

- Permeate containing the fabric that passes through the membranes, and retentate consists of species being left behind.

- Membrane filtration also can be labeled in phrases of the dimensions variety of the permeating species, the rejection mechanisms, the riding forces employed, the chemical shape and composition of the membranes, and the geometry of the construction.

- The maximum vital kinds of membrane filtration are microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and Reverse osmosis (RO).

Q13) What is RSF?

A13)

- Rapid sand filtration is a simply bodily ingesting water purification method. Rapid sand filters (RSF) offer fast and green elimination of notably huge suspended particles.

- Two sorts of RSF are commonly used: fast gravity and fast stress sand filters. For the availability of secure ingesting water, RSFs require good enough pre-remedy (commonly coagulation-flocculation) and post-remedy (commonly disinfection with chlorine).

- Both production and operation is cost-intensive. It is a notably state-of-the-art method commonly requiring power-operated pumps, everyday backwashing or cleaning, and glide manipulate of the clear out outlet.

- Rapid sand filtration is not unusualplace in advanced international locations for the remedy of huge portions of water in which land is a strongly proscribing factor, and in which material, professional labour, and non-stop electricity deliver are to be had.

Advantages

- Highly powerful for elimination of turbidity (commonly < 0.1-1 NTU)

- High clear out rate (4’000 – 12’000 litres according to hour according to rectangular metre of surface), small land requirements

- No barriers concerning preliminary turbidity levels (if coagulant or flocculant is to be had and successfully applied)

- Cleaning time (backwashing) most effective takes numerous mins and filters may be placed again into operation instantly

Disadvantages

- Not powerful in casting off bacteria, viruses, fluoride, arsenic, salts, odour and natural matter (calls for pre- and post-remedy)

- High capital and operational costs Frequent cleaning (backwashing) required (each 24-72h) Skilled supervision essential (e.g. For glide manipulate and dosage of disinfectant)

- High electricity enter required Backwashing water and sludge desires remedy; sewage device or stabilisation ponds required

Q14) What is SSF?

A14)

- Slow sand filtration is a sort of centralised or semi-centralised water purification system.

- A well-designed and well maintained sluggish sand clear out out (SSF) efficaciously eliminates turbidity and pathogenic organisms through diverse organic, bodily and chemical strategies in a unmarried remedy step. Only below the superiority of a drastically excessive diploma of turbidity or algae-contamination, pre-remedy measures (e.g. Sedimentation) grow to be necessary.

- Slow sand filtration structures are characterized with the aid of using a excessive reliability and alternatively low lifecycle costs. Moreover, neither creation nor operation and renovation require extra than fundamental abilties. Hence, sluggish sand filtration is a promising filtration technique for small to medium-sized, rural groups with a reasonably top great of the preliminary floor water source.

- As said with the aid of using the WHO, sluggish sand filtration gives a easy however enormously powerful and significantly reasonably-priced device which can make a contribution to a sustainable water control system.

Advantages

- Very powerful elimination of bacteria, viruses, protozoa, turbidity and heavy metals in infected sparkling water Simplicity of layout and excessive self-assist compatibility: creation, operation and renovation simplest require fundamental abilties and information and minimum effort

- If built with gravity go with the drift simplest, no (electrical) pumps required Local substances may be used for creation

- High reliability and cap potential to resist fluctuations in water great

- No necessity for the utility of chemicals

- Easy to put in in rural, semi-city and far flung areas, Simplicity of layout and operation Long lifespan (estimated >10 years)

Disadvantages

- Minimal great and consistent go with the drift of sparkling water required: turbidity (<10-20 NTU) and coffee algae contamination.

- Otherwise, pre-remedy can be necessary Cold temperatures decrease the performance of the procedure because of a lower in organic activity

- Loss of productiveness for the duration of the pretty lengthy clear out out skimming and ripening periods

- Very everyday renovation essential; a few fundamental system or ready-made take a look at kits required to reveal a few bodily and chemical parameters

- Possible want for adjustments in attitude (notion that water that flows through a inexperienced and slimy clear out is secure to drink without the utility of chemicals), Chemical compounds (e.g. Fluorine) aren't removed Natural natural depend and different DBPs precursors now no longer removed (can be fashioned if chlorine is implemented for very last disinfection)

- May require electricity Requirement of a huge land area, huge portions of clear out out media and guide labour for cleaning, Low filtration rate

Q15) What is pressure filter?

A15)

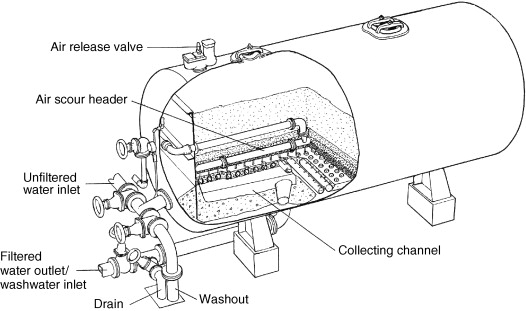

- Pressure filters are comparable in mattress production to speedy gravity filters, besides that they're contained in a metal stress vessel. Perforated pipes or a metal plate with nozzles are used for accumulating the filtered water and for distribution of the washwater and air scour.

- The metal stress vessel is cylindrical, organized horizontally (Fig.) or vertically. With a pipe lateral underdrain device the lowest of the vessel is typically packed with concrete a good way to attain a flat base. In the plenum ground layout a metal plate into which nozzles are screwed, is used. In a horizontal vessel, occasionally vertical plates are welded inner to present a square formed sand mattress in the cylinder in order that the mattress can be washed flippantly and there are no ‘dead’ regions underneath which air scour and water pipes cannot be located.

- More typically media is located withinside the whole vessel such that the intensity is similarly dispensed approximately the horizontal diameter of the filter. The entire of the cylinder is stored packed with water beneathneath stress and at the very best factor an air launch valve is inserted for the discharge of trapped air.

- To keep away from having to hire unique transportation approaches for massive masses the most diameter of filters is restrained to 3–four m and the length/peak is restrained to approximately 12 m.

Fig: Pressure filter

- The backwashing of such filters may be very just like that of an open speedy gravity clear out. A bellmouth and pipe may be used for the elimination of grimy washwater in a vertical clear out; for maximum horizontal filters a unmarried vertical plate positioned close to one of the dished ends helps washwater elimination, however for the bigger filters, a critical washout channel fashioned through vertical plates is necessary.

- The gain of strain filters is that extra uncooked water strain isn't always misplaced whilst the filtration procedure takes place, as is the case with an open speedy gravity clear out system. About three m head can be misplaced in friction through the sand mattress and the inlet and outlet fittings. This consists of an allowance for dust lack of approximately 1.5–1.eight m.

- This blended head loss is among the not unusualplace inlet and outlet bus mains serving a battery of filters. Pressure filters can be interposed on a pumped or gavity pipeline without a big lack of strain at the supply.

- Air binding, as a result bad head, ought to now no longer arise in strain filters if the strain withinside the media is usually above that on the factors upstream in which air should have been given into solution.

Q16) What are elements of filters sand specification?

A16)

- There are 3 most important types; speedy (gravity) sand filters, upward go with the drift sand filters and sluggish sand filters.

- All 3 strategies are used appreciably withinside the water enterprise at some stage in the world. The first require using flocculant chemical substances to paintings correctly at the same time as sluggish sand filters can produce very excessive best water with pathogens elimination from 90% to >99% (relying at the strains), flavor and odour without the want for chemical aids. Sand filters can, aside from being utilized in water remedy plants, be used for water purification in singular families as they use substances which can be to be had for maximum people.

- As the identify indicates, the rate of filtration is modified withinside the sluggish sand clear out, however, the largest distinction among sluggish and speedy sand clear out, is that the pinnacle layer of sand is biologically active, as microbial groups are delivered to the system.

- The encouraged and normal intensity of the clear out is 0.nine to 1.five meters. Microbial layer is shaped inside 10–20 days from the begin of the operation. During the method of filtration, uncooked water can percolate via the porous sand medium, preventing and trapping natural material, bacteria, viruses and cysts along with Giardia and Cryptosporidium.

- The regeneration manner for sluggish sand filters is known as scraping and is used to robotically get rid of the dried out debris at the clear out. However, this method also can be executed below water, relying at the character system. Another restricting issue for the water being dealt with is turbidity, that's for sluggish sand filters described to be 10 NTU (Nephelometric Turbidity Units).

- Slow sand filters are an excellent alternative for confined finances operations because the filtration isn't the usage of any chemical substances and calls for very little mechanical assistance. However, due to a non-stop developing populace in groups, sluggish sand filters are being changed for speedy sand filters, normally because of the walking duration length.

Characteristics | Rapid sand filter | Slow sand filter |

Filtration rate [m/h] | 5–15 | 0.08–0.25 |

Media effective size [mm] | 0.5–1.2 | 0.15–0.30 |

Bed depth [m] | 0.6–1.9 | 0.9–1.5 |

Run length | 1–4 days | 1–6 months |

Ripening period | 15 min – 2 h | Several days |

Regeneration method | Backwashing | Scraping |

Maximum raw-water turbidity | Unlimited with proper pretreatment | 10 NTU |