Unit – 1

QUESTION BANK

- What is scope of Civil Engineering?

Civil Engineering is that field of engineering concerned with planning, design and construction for environmental Control, development of natural resources, buildings, transportation facilities and other structures required for health, welfare, safety, employment and pleasure of mankind"

The main scope of civil engineering or the task of civil engineering is planning, designing, estimating, supervising construction, managing construction, execution, and maintenance of structures like building, roads, bridges, dams, etc. ' One who designs and maintains works of public utility is known as civil engineer. Civil engineer should have qualities like scientific attitude, imaginative and intuitive approach, He should have good analysis and decision power. He should be able to solve engineering problems, by using mathematical modelling, scientific principles and laboratory techniques using computer and information technology. He should be able to use operation research techniques for solution of management problems.

2. Describe Role of Engineers in the infrastructure development?

A civil engineer has to conceive, plan, estimate, get approval, create and maintain all civil engineering activities.

Civil engineer has very important role in the development of the following infrastructure:

- Measure and map the earth’s surface.

- Plan new townships and extension of existing towns

- Build the suitable structures for the rural and urban areas for various utilities

- Build tanks and dams to exploit water resources.

- Build river navigation and flood control projects.

- Provide and maintain communication systems like roads, railways, harbours and airports

- Purify and supply water to the needy areas like houses, schools, offices etc.

- Build canals and distributaries to take water to agricultural fields

- Devise systems for control and efficient flow of traffic

- Provide and maintain solid and waste water disposal system

- Monitor land, water and air pollution and take measures to control them

Fast growing industrialization has put heavy responsibilities on civil engineers to preserve and protect environment.

3. What are the Factors affecting selection of site?

The site for a residential building should, present a peaceful environment , good landscape, sun for the most part of the day and uninterrupted flow of natural air. The following factors need to be studied in depth, while selecting the site for a residential building:

- Topography

- Nature of sub-soil

- Position of the ground water table

- Facilities

- Neighbourhood

- Undesirable things near the site

- Vegetation

- Shape of the site

- Availability of men and materials

- Proximity to sea-shore, river or lake or the place of natural beauty

4. List and describe the Principles of planning?

Importance of Planning, Scheduling, and Construction Management

Management is a social and scientific process of defining the objectives, planning, organizing, coordinating, motivating, controlling and harnessing the resources of an organization at the optimum level to achieve predetermined goal.

Principal of Planning

- Aspect

- Prospect

- Privacy

- Circulation

- Roominess

- Grouping

- Elegance

- Sanitation

- Flexibility

- Economy

- Practical consideration

Aspect

Placement of different rooms of house in accordance with our activities at different hours of day. Rooms should get enough sunlight and air, which gives, Great environment, Comfort etc. A room which receives light & air from particular direction is said to have ‘aspect’ of that direction.

Prospect

Prospect is the view from outside of a house. The house should have a proper prospect so that it can give a feeling of cheerfulness to the people living in it. It should create a good impression on a person who views it from outside. It must also possess good qualities like comfort, cheerfulness, security, labour saving and modern outlook. For e.g. Small Projections or bay window can have a good out-look as well as helps in providing breeze, light and sunlight to the room.

Privacy

It is an important principle while planning a residential building. Privacy can be maintained in ways: 1. External 2. Internal

- External Privacy

The privacy from sides can be secured by providing planned entrance and pathways. This can achieve by screening the front and rear entrance.

2. Internal Privacy

Privacy in internal rooms can be easily obtain by proper planning of diff. Areas and location of doors and windows. The shutter when opened should give the minimum view of room for an entering person.

Circulation

Circulation is movement within the premises and includes both horizontal and vertical circulation. Horizontal circulation (room to room), Passage, Corridors, Lobbies etc. Vertical circulation (floor to floor) - Stairs

Roominess

Roominess means getting maximum advantage from the minimum dimension of the room. The effect of roominess depends on the relative dimension of length, width and height of room. The shape and size of the room are also very important for roominess. A rectangular room has more roominess then square room in same area.

Grouping

Grouping means the arrangement of various rooms in the building for the convenience of user. It minimizes the circulation and at the same time improves the comfort. A dining room should be close to kitchen ,while sanitary be away from kitchen, but convenient to bed rooms.

Elegance

Elegance is grand appearance of a building attained mainly owing to the elevation which in turn depends on the plan. It depends upon proper positioning/selection of doors, windows, balcony, roofs, staircase etc. For better elegance. Selecting superior building material for facing as polished stone- granite, marble or mosaic. Providing projection like sunshades, balconies, porch with or without pergola opening. Providing bay window, corner window, etc.

Sanitation

It includes providing light, ventilation, cleanliness, water supply and sanitary amenities. For residential building window area should not less than 1/10th of floor area. In school not less than 1/5th of the floor area.

Flexibility

Flexibility means that a room which is planned for one function be used for other, if required. Like study room may be planned for using guest room. Etc.

Economy

The building should have minimum floor area with maximum utility. It will reduce cost of the building. Hence, it will be economical. Economy can achieve by: Providing simple elevation. Reducing the storey height. Dispensing of porches, lobbies and balconies.

Practical Consideration

After the all fundamental some practical points should be additionally considered: Provision for future extensions without dismantling should be made while planning. Strength, stability, convenience and comfort of occupants, should be the first consideration while planning. As far as possible sizes of rooms should be kept large. Large room can be shortened by providing movable partition but smaller room cannot be enlarged easily. The number of door and window should be minimum provisions for built in furniture at proper places are useful from point of view of utility.

5. Define Height of building, open space requirement, F.S.I., Carpet area, built up area, setbacks, ventilation

Height of building

Building height means the average maximum vertical height of a building or structure measured at a minimum of three equidistant points from finished grade to the highest point on the building or structure along each building elevation. Architectural elements that do not add floor area to a building or structure, such as parapet walls, chimneys, vents, and roof equipment are not considered part of the height of a building or structure (See page 3 for special restrictions in the Central Business and Waterway Overlay zones).

Height of building according to width of street:

1. The maximum height of the building shall not exceed 1.5 times the width of road.

2. For building in vicinity of aerodromes, the maximum height of the building is fixed in consultation with civil aviation authorities.

The height shall not include if building is erected one-third of roof area, including:

1. Roof tank and its support

2. Ventilating, lift room

3. Roof structure other than pent-house

Open space requirement

Open air space for ventilation. Every room intended for human habitation should abut an interior or exterior opening air space of the width r dimensions specified below.

F.S.I.,

FSI stands for Floor Space Index also known as Floor Area Ratio (FAR). FSI means the ratio between the area of a covered floor (Built up Area) to the area of that plot (land) on which a building stands.

It is calculated by dividing the total covered built-up area on all floors of a building by the area of the plot it stands on. For instance, if you have 1,000 square feet of land on which you want to build a residential or commercial building and the FSI in your locality is 1.5, then you could build up to 1,500 sq.

Carpet area

Carpet area is the area that can be used to spread a carpet inside the house. It is the net usable area of the apartment. It includes the thickness of the internal wall but excludes balcony or terrace. Technically, the distance between inner walls is carpet area.

Built up area

Built up Area is the carpet area plus the thickness of outer walls and the balcony. Super Built Up Area is the built-up area plus proportionate area of common areas such as the lobby, lifts shaft, stairs, etc. Sometimes it may also include the common areas such, swimming pool, garden, clubhouse, etc.

Setbacks

In land use, a setback is the minimum distance which a building or other structure must be set back from a street or road, a river or other stream, a shore or flood plain, or any other place which is deemed to need protection.

Ventilation

Ventilation moves outdoor air into a building or a room, and distributes the air within the building or room. The general purpose of ventilation in buildings is to provide healthy air for breathing by both diluting the pollutants originating in the building and removing the pollutants from it

Building ventilation has three basic elements:

- Ventilation rate — the amount of outdoor air that is provided into the space, and the quality of the outdoor air

- Airflow direction — the overall airflow direction in a building, which should be from clean zones to dirty zones; and

- Air distribution or airflow pattern — the external air should be delivered to each part of the space in an efficient manner and the airborne pollutants generated in each part of the space should also be removed in an efficient manner.

There are three methods that may be used to ventilate a building: natural, mechanical and hybrid (mixed-mode) ventilation.

6. What are the different Types of loads on buildings?

INTRODUCTION

Simply, loads are some sort of force. Major types of loads:

- Dead loads. (red arrow) - Exerted by the weight of the element of the structure.

- Live loads. (rest arrow) - Exerted by any temporary force acting on the structure Loads in simple structure

DEAD LOADS

Dead Loads are those loads which are considered to act permanently; they are "dead," stationary, and unable to be removed. The self-weight of the structural members normally provides the largest portion of the dead load of a building. Exerted by the weight of the element of the structure

LIVE LOADS

Live Loads are not permanent and can change in magnitude. They include items found within a building LIVE LOADS All the arrows indicate the live loads unless the red one.

Wind load

The wind's relatively large projected areas can develop substantial forces in the structure.

Earthquake loads are another lateral live load.

They are very complex, uncertain, and potentially more damaging than wind loads. LIVE LOADS EARTHQUAKE LOADS: Mass tends to remain in its original position, deformation due to sudden ground moving take place at the base

POINT LOAD OR CONCENTRATED LOAD

The load concentrated at one point is called point load. Unit of point load is N or kN. e.g. 20kN,100N etc. W1 and W2 are point loads.

UNIFORMLY DISTRIBUTED LOAD

Load uniformly distributed on certain length of a beam is called uniformly distributed load. It is written as u.d.l. It is shown by w. Unit of u.d.l. Is kN/m or N/m.

UNIFORMLY VARYING LOAD

This type of load gradually increase or decrease on the length of the beam. It is also called triangular load.

7. What are the Types of soils?

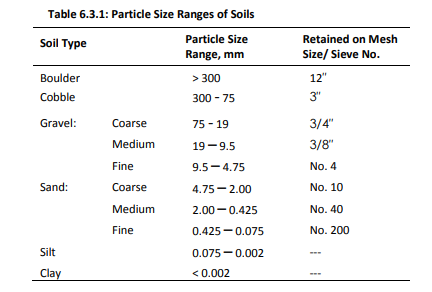

Soils are divided into three major groups, coarse grained, fine grained and highly organic. The classification is based on classification test results namely grain size analysis and consistency test. The coarse-grained soils shall be classified using Table Outlines of organic and inorganic soil separations are also provided in Table The fine-grained soils shall be classified using the plasticity chart. In addition to these classifications, a soil shall be described by its colour, particle angularity (for coarse grained soils) and consistency. Further to the above classification soils exhibiting swelling or collapsing characteristic shall be recorded. For undisturbed soils information on stratification, degree of compactness, cementation, moisture conditions and drainage characteristics shall be included.

1. Sand

It is most extensively used construction material. It consists of particles of rock and hard minerals, such as silicon dioxide. They are the largest type of soil particles, where each particle is visible to naked eye. The large, relatively stable sand-particle size increases soil aeration, improves drainage in tight soils and creates plant-growth supporting qualities, or tilt.

Sand

The particle size of course sand ranges from 2 – 4.75mm, Medium sand ranges from 0.425 – 2 mm and fine sand ranges from 0.075 – 0.425 mm. The bigger particle size of the sand gives wet or dry sandy soil a grainy texture when you rub it between your fingers, and it makes the soil light and crumbly even when you try to stick it together in your hand. The particle shape is angular, sub angular, rounded, flat or elongated. The texture is rough, smooth, or polished.

2. Silt

Silt is a sediment material with an intermediate size between sand and clay. Carried by water during flood it forms a fertile deposit on valleys floor. The particle size of silt ranges from 0.002 and 0.06 mm.

Silt in wet condition

Silt is a non-plastic or low plasticity material due to its fineness. Due to its fineness, when wet it becomes a smooth mud that you can form easily into balls or other shapes in your hand and when silt soil is very wet, it blends seamlessly with water to form fine, runny puddles of mud.

3. Clay

Clay particles are the finest of all the soil particles, measuring fewer than 0.002 mm in size. It consists of microscopic and sub-microscopic particles derived from the chemical decomposition of rocks. Clay is a fine grained cohesive soil. They stick together readily and form a sticky or gluey texture when they are wet or dry.

Clay when mixed with water

Clay is made of over 25 percent clay, and because of the spaces found between clay particles, clay soils hold a high amount of water. Clay expand when in contact with water and shrink when getting dry. Compared to sand particles, which are generally round, clay particles are thin, flat and covered with tiny plates. Organic clay is highly compressible and its strength is very high when dry, which is why it is used in construction as mud mortar.

4. Loam

Loam is a mixture of clay, sand and silt and benefits from the qualities of these 3 different textures, favouring water retention, air circulation, drainage and fertility. These soils are fertile, easy to work with and provide good drainage. Depending on their predominant composition they can be either sandy or clay loam.

Loam

The way the other particles combine in the soil makes the loam. For instance, a soil that is 30 per cent clay, 50 per cent sand and 20 per cent silt is a sandy clay loam, with the soil types before “loam” listed in the order their particles are most dominant in the loam. The labels “clay loam,” “silt loam” and “sand loam” are used to refer to soils that are composed predominantly of those ingredients.

8. Describe Concept of bearing capacity?

In geotechnical engineering, bearing capacity is the capacity of soil to support the loads applied to the ground. The bearing capacity of soil is the maximum average contact pressure between the foundation and the soil which should not produce shear failure in the soil. Ultimate bearing capacity is the theoretical maximum pressure which can be supported without failure; allowable bearing capacity is the ultimate bearing capacity divided by a factor of safety. Sometimes, on soft soil sites, large settlements may occur under loaded foundations without actual shear failure occurring; in such cases, the allowable bearing capacity is based on the maximum allowable settlement.

There are three modes of failure that limit bearing capacity: general shear failure, local shear failure, and punching shear failure. It depends upon the shear strength of soil as well as shape, size, depth and type of foundation.

9. What are the Types of foundation?

FOUNDATION:

Lower part of the structure which is in direct contact with the soil and transmits loads to the ground.

- DEEP FOUNDATION: A foundation unit that provides support for a structure transferring loads by end bearing and/or by shaft resistance at considerable depth below the ground. Generally, the depth is at least five times the least dimension of the foundation.

- SHALLOW FOUNDATION: A foundation unit that provides support for a structure transferring loads at a small depth below the ground. Generally, the depth is less than two times the least dimension of the foundation.

- FOUNDATION ENGINEER: A graduate Engineer with at least five years of experience in civil engineering particularly in foundation design or construction.

10. Different types of Cement

Types of Cements

Ordinary Portland cement

Ordinary Portland cement is the most common type of cement in general use around the world. This cement is made by heating limestone (calcium carbonate) with small quantities of other materials (such as clay) to 1450°C in a kiln, in a process known as calcination, whereby a molecule of carbon dioxide is liberated from the calcium carbonate to form calcium oxide, or quicklime, which is then blended with the other materials that have been included in the mix. The resulting hard substance, called 'clinker', is then ground with a small amount of gypsum into a powder to make 'Ordinary Portland Cement'(often referred to as OPC). Portland cement is a basic ingredient of concrete, mortar and most non-specialty grout. The most common use for Portland cement is in the production of concrete. Concrete is a composite material consisting of aggregate (gravel and sand), cement, and water. As a construction material, concrete can be cast in almost any shape desired, and once hardened, can become a structural (load bearing) element. Portland cement may be grey or white.

Rapid hardening Portland cement

- It is firmer than Ordinary Portland Cement

- It contains more C3S are less C2S than the ordinary Portland cement.

- Its 3 days strength is same as 7 days strength of ordinary Portland cement. Low heat Portland cement

- Heat generated in ordinary Portland cement at the end of 3days 80 cal/gm. While in low heat cement it is about 50cal/gm of cement.

- It has low percentage of C3A and relatively more C2S and less C3S than O.P. Cement.

- Reduce and delay the heat of hydration. British standard ( B S. 1370 : 1974 ) limit the heat of hydration of this cement.

Sulphate resisting Portland cement

- For this cement, the silage as obtained from blast furnace is used

- The clinkers of cement are ground with about 60 to 65 percent of slag.

- Its strength in early days is less and hence it required longer curing period. It proves to be economical as slag, which is a Waste product, is used in its manufactures.

Pozzolanic cement

- As per Indian standard, the proportions of Pozzolana may be 10 to 25 % by weight. e.2. Burnt clay, shale, Fly ash.

- This Cement has higher resistance to chemical agencies and to sea water because of absence of lime.

- It evolves less heat and initial strength is less but final strength is 28 days onward equal to ordinary Portland cement.

- It possesses less resistance to the erosion and weathering action.

- It imparts higher degree of water tightness and it is cheap.

White Portland cement

- Grey colour of O.P. Cement is due to presence of Iron Oxide. Hence in White Cement Fe,,O, is limited to 1 %. Sodium Alumina Ferrite (Crinoline) NavAlF6 is added to act as flux in the absence of Iron-Oxide.

- It is quick drying, possesses high strength and has superior aesthetic values and it also cost lee than ordinary Cement because of specific requirements imposed upon the raw materials and the manufacturing process. White Cement are used in Swimming pools, for painting garden furniture, moulding sculptures and statues etc.

Coloured Portland Cement

- The Cement of desired colour may be obtained by mixing mineral pigments with ordinary Cement.

- The amount of colouring material may vary from 5 to 10 percent. If this percentage exceeds 10percent, the strength of cements is affected.

- The iron Oxide in different proportions gives brown, red or yellow colour. The coloured Cement are widely used for finishing of floors, window sill slabs, stair treads etc.

Expansive cement

- This type of cement is produced by adding an expanding medium like sulpho aluminate and a stabilising agent to the ordinary cement.

- The expanding cement is used for the construction of water retaining structures and for repairing the damaged concrete surfaces.

High alumina cement

- This cement is produced by grilling clinkers formed by calcining bauxite and lime. It can stand high temper lures.

- If evolves great heat during setting. It is therefore not affected by frost.