UNIT-IV

IMPORTANT QUESTIONS

1- Define oxidation pond and its bacteria algae symbiosis ?

Oxidation pond is a type of wastewater treatment which also known as lagoons or water stabilization pond. It is a secondary treatment of wastewater coming from industries, residential areas ,rural areas etc.

Oxidation pond can be defined as the stabilization pond that stabilizes the domestic, trade, industrial wastes etc. by the microbial interaction, primarily bacteria and algae. It is the large, shallow ponds having 2-6 feet height of water body. Oxidation pond requires the presence of sunlight and oxygen for the secondary treatment of domestic and trade wastes. The secondary treatment of the organic and inorganic waste coming from raw sewage and industrial effluents is necessary. The direct disposal of the wastewater to the aquatic system can affect the life of water-bodies and the quality of water as well. They are used to treat sewage and bio degradable industrial waste. These are aerobic, anaerobic , facultative.

Bacteria – algae symbiosis-

In the totally aerobic pond the stabilization of wastes is brought out by aerobic bacteria which flourish in the presence of oxygen . The oxygen demand of such a bacteria in such a pond is met by combined action of algae and other micro organisms called algal photosynthesis or algal symbiosis.

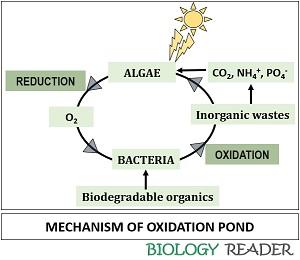

The mechanism of working of the oxidation can be made simple by understanding the following steps:

First, the bacteria present in the oxidation pond will oxidize the organic waste of the domestic as well as industrial sewage. By doing this, bacteria release carbon dioxide, water and ammonia. The algal growth occurs in the presence of sunlight. It utilizes the inorganic waste formed by the organic matter decomposition and releases oxygen. The oxygen demand o such bacteria in such a pond is met by combined action of algae and other micro organisms such as bacteria and protozoa called algal photosynthesis or algal- symbiosis.

From the above two mechanisms, it is clear that the algae and bacteria work corporately to fulfil each other’s requirement. The bacteria use oxygen released by the algae, to oxidize the biodegradable organics..

2- Design procedure of oxidation pond as per the CPHEEO ?

The surface area of tank may be worked out by assuming a suitable value of organic loading .which may range between 300-150kg/hect/day. Or so in hot tropical countries like india to about 90-60 kg/hect/day . Each unit may have an area ranging between 0.5 to 1 hectare.

The length of tank may be kept as twice of its width. The depth may be kept between 1-1.5m . A free board of about 1m may also be provided corresponding to 20-30 day of detention period.

IS5611 recommends the following values of BOD loading over different parts of country depending upon temperature and latitude of place –

Latitude N BOD loading in kg/ha/day

8 325

12 300

16 275

20 250

24 225

28 200

32 175

36 150

Detention period in days = 1/Kd log 10(L/L-Y)

Where,

L=the BOD of effluent entering the pond

Y=the BOD removed say 90% of L

Results obtained- properly operated ponds may be effective as trickling filters in reducing the BOD of sewage . The BOD removal is upto 90%.

3- design an oxidation pond for treating sewage from hot colony with 5000 persons contributing sewage @120 litres per capita per day . The 5-day BOD of the sewage is 300 mg/l.

The quantity of sewage treated per day=5000*120=600000lit

=0.6 Mlit

The BOD content per day=0.6*300mg/l=180kg

Now assuming the organic loading in the pond say 300 kg/ha/d

180kg/d

Surface area required = ________=6000 square-m

300kg/ha/d

Assuming the length of tank twice its width

2B2=6000

B=54.7=55m

L= 6000/55 =110m

Using a tank with effective depth as 1.2m we have

The provided capacity = 110*55*1.2=7260 cubic-m

Now capacity = sewage flow per day * detention time in days

Detention time in days = capcity/ sewage flow per day

=7260/600=12.1 days = 12 days

Hence use an oxidation pond with length 110m, width 55m, and overall depth 1.2+1=2.2m and detention period 12 days.

4- write down the principle of aerated lagoons and its types?

Principle-

Pond systems, in which oxygen is provided through mechanical aeration rather than algal photosynthesis are called aerated lagoons.

An aerated lagoon is a suspended-growth process in waste water treatment unit. The aerated lagoon water treatment system consists of a large earthen lagoon or basin that is equipped with mechanical aerators to maintain an aerobic environment and to prevent settling of the suspend biomass. It is provided with inlet at one end and outlet at the other end to enable the wastewater to flow through and to retain for the specified detention time.

According to our experience sludge in the inlet zone of first aerated wastewater lagoons has to be removed at regular interval of several years. Dissolved and suspended organic pollutants are distributed in whole first lagoon. The treatment process in lagoon is similar to natural process in the flowing water bodies . Biological degradation of pollutants depends on attached growth.

Types of lagoons-

Depending on how the microbial mass of solids is handled in the aerated lagoons the same are classified as:

(i) Facultative aerated lagoons

(ii) suspended mixed lagoons

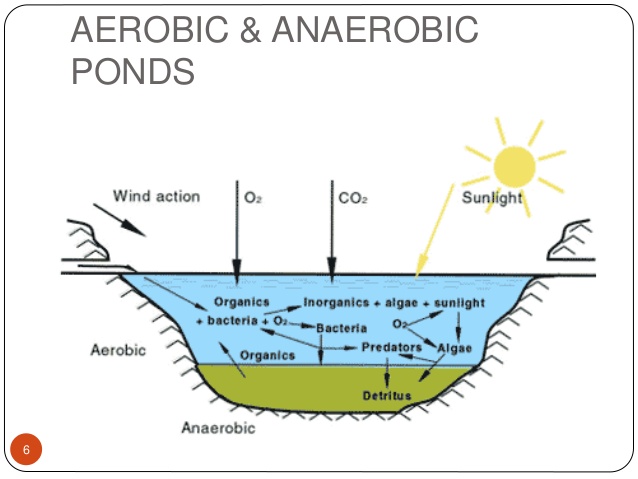

(i) Facultative Aerated Lagoons:

Facultative lagoons used to treat domestic wastewaters provide an example of a highly stressed aquatic ecosystems. These lagoons consist of a shallow basin in which settleable solids introduced by the wastewater settle to the bottom to for a sludge layer that decomposes anaerobically. If oxygen is present in the water column, the biodegradable organic materials that do not settle are degraded aerobically. The term facultative describes the aerobic-anaerobic nature of the lagoon - an anaerobic bottom region covered by an aerobic top layer. The depth of the latter is in a state of constant fluctuation as the result of changing meteorological conditions. The dominant organisms in the system are algae and bacteria which function in a mutually beneficial relationship.

(ii) suspended mix lagoons-

These are the lagoons when there is less energy provided by the aeration equipment to keep the sludge in suspension.

Facultative type aerated lagoons have been more commonly used the world over because of their simplicity in operation and minimum need of machinery. They are often referred to simply as ‘aerated lagoons’.

5- What are the advantages and disadvantages of aerated lagoons?

Advantages of Aerated Lagoons:

The various advantages of aerated lagoons are as indicated below:

(i) The aerated lagoons are easy in operation, the only moving piece of equipment being the aerator.

(ii) The removal efficiencies in terms of power input are comparable to some of the other aerobic treatment methods.

(iii) Civil construction mainly entails earthwork, and land requirement is not excessive. Aerated lagoons require only 5 to 10 percent as much land as stabilization ponds.

(iv) The aerated lagoons are used frequently for the treatment of industrial wastes.

Disadvantages of aerated lagoons-

(1) it produces odour nuisance when their functioning starts.

(2) Significant loss of manure nitrogen fertilizer.

(3) Need for periodic sludge removal.

(4) Need for final disposal of lagoon contents by irrigation or tank wagon.

(5) breeding of mosquitoes takes place.

(6) Cost of equipment and electrical energy if aerators are needed.

(7) There is no economically feasible method of treating livestock manure so that the lagoon contents can be discharged to a watercourse without pollution.

(8) Lagoon systems require more land than other treatment methods.

(9) They are less efficient in cold climates and may require additional land.

(10) Odour can become a nuisance during algal blooms or with anaerobic lagoons and lagoons that are inadequately maintained.

6- Explain phytoremediation theory of sewage treatment?

Phytoremediation is one of the biological methods that can be used in remediation of polluted sites in situ. There are various techniques of phytoremediation which are applicable in wastewater treatment, in surface water and groundwater purification, in the removal of excessive nutritive substances from water reservoirs, and in reclamation of soil polluted as a result of environmental disasters.

Water is the essential source of life on the earth as we need water in every walk of life on one side, on other side polluted water can be lethal for existing life. Water pollution is the contamination of water bodies (e.g. Lakes, rivers, oceans, aquifers and groundwater). This form of environmental degradation occurs when pollutants are directly or indirectly discharged into water bodies without adequate treatment to remove harmful compounds. Various treatment methods have been employed to cleanup polluted sites.At present a wide range of phytotechnologies have emerged to prevent environmental degradation.. Phytoremediation is the name of a set of technologies that use plants to degrade, extract, or contain contaminants from soil and water. This topic has been the great deal of research over the last ten years. Phytoremediation is the direct use of living green plants for in situ, or in place, removal, degradation, or containment of contaminants in soils, sludges, sediments, surface water and groundwater.The mobilization of heavy metals by man through extraction from ores and processing for different applications has led to the release of these elements into the environment. Since heavy metals are non-biodegradable, they accumulate in the environment. This contamination poses a risk to environmental and human health. Some heavy metals are carcinogenic, mutagenic, teratogenic and endocrine disruptors while others cause neurological and behavioral changes especially in children. Thus remediation of heavy metal pollution deserves due attention. Phytoremediation is a relatively recent technology and is perceived as cost-effective, efficient, novel, eco-friendly, and solar-driven technology with good public acceptance. Phytoremediation is an area of active current research. New efficient metal hyper accumulators are being explored for applications in phytoremediation and phytomining. Molecular tools are being used to better understand the mechanisms.

There are several advantages and disadvantages of phytormediation techniques . one of the biggest advantage is low cost as compared to another conventional methods

7- What is root zone cleaning system in brief?

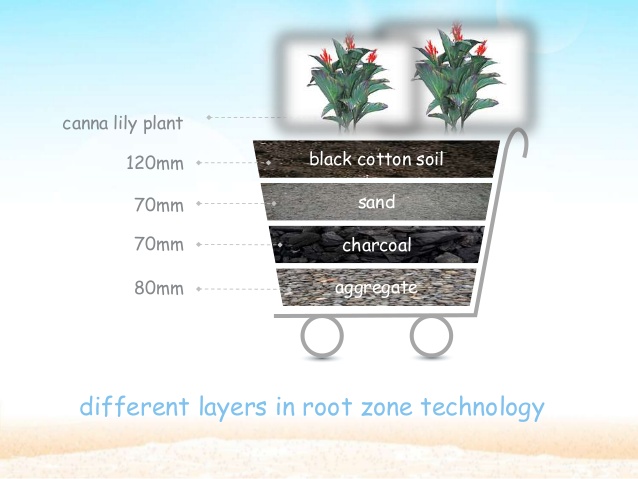

Root zone technology is effective technology called decentralized wastewater system.

Various types of plants are used in root zone treatment such as canna lily ,reed, thyfa latifolia etc

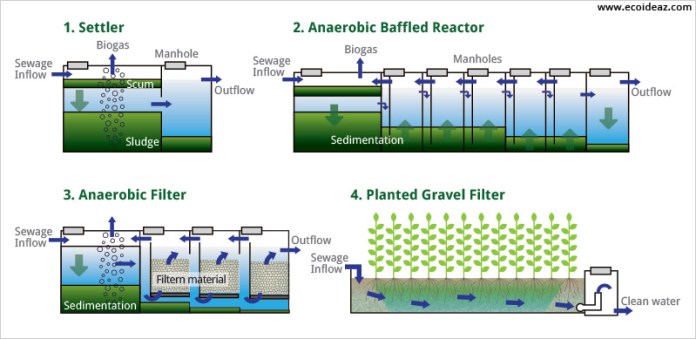

There are various layers of this system as shown in fig below.

The root zone waste water treatment system makes use of biological and physical-treatment processes to remove pollutants from wastewater. Due to its natural process, there is no need to add any input such as chemicals, mechanical pumps or external energy. This reduces both the maintenance and energy costs.

o accomplish this, the root zone wastewater treatment undertakes the following steps:

- Pre-treatment done in a Settler – a device that separates the liquid from the solid

- First treatment takes place in a Anaerobic Baffled Reactor – a device with several identical chambers through which the effluent moves from top to bottom.

- Second treatment happens in an Anaerobic Filter – a device filled with a filter material (cinder), through which the effluent moves from top to bottom.

- Third treatment takes place in a Planted Gravel Filter – a structure filled with gravel material and planted with water-resistant reed plants, which provide oxygen to the passing effluent.

1. Settler | 2. Anaerobic Baffled Reactor | 3. Anaerobic Filter | 4. Planted Gravel Filter

The Root Zone Waste Water Treatment system takes into account the natural slope of the ground, so that water flows from one device to another without any external energy input such as motor pump. Once the reed plants create an established stand, usually after the first growing season, the reed bed requires little or no maintenance. The plant foliage will soon blend naturally into the landscape, ever changing with the seasons and creating a pleasing sight as well!

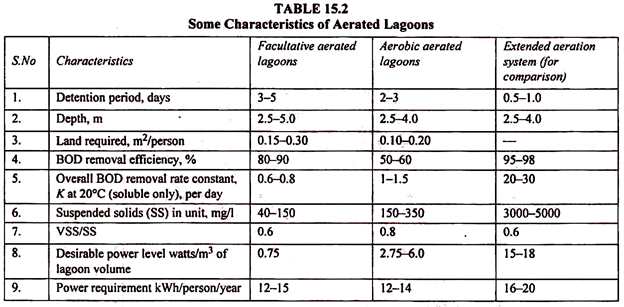

8- What is the design procedure or aerated lagoons?

Design of aerated lagoons-

Design Variables:

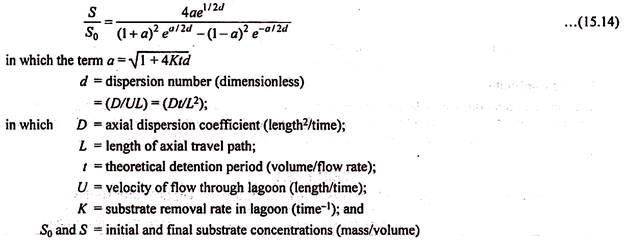

For facultative aerated lagoons, the dispersed flow model gives the relation between influent and effluent substrate concentrations, S0 and S, respectively and other variables such as the nature of the waste, the detention period and the mixing conditions, as shown in the Wehner-Wilhem equation given below-

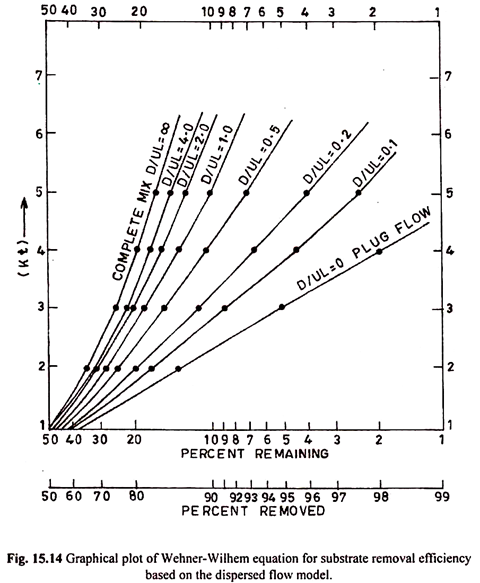

A graphical solution of equation 15.14 is shown in Fig. 15.14 from which it is seen that prior knowledge of the substrate removal rate K as well as of the mixing condition likely to prevail in a lagoon is necessary to determine the efficiency of BOD removal at selected detention period. This is discussed below.

Mixing Conditions:

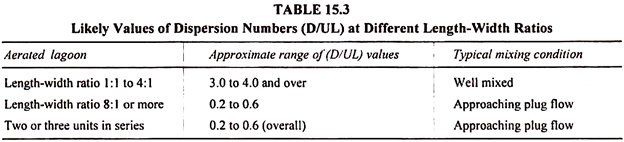

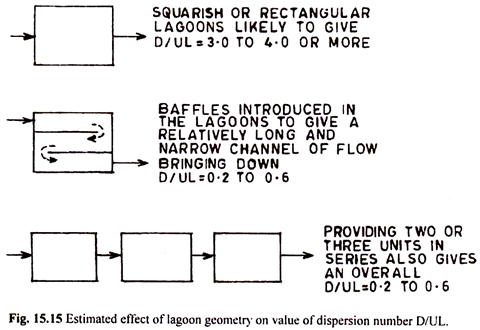

The mixing conditions in a lagoon are reflected by the term d which is known as the dispersion number and equals (D/UL) or (Dt/L2). It is affected by various factors. Observed results have shown the (D/UL) values to be in the approximate range given in Table 15.3 for different length-width ratios of lagoons.

For municipal or domestic sewage, relatively plug flow type conditions (i.e., low values of DU/L) are preferred. In case of industrial wastes, relatively well mixed conditions (i.e., higher values of D/UL) may be preferred depending upon the nature of industrial waste; the greater the fluctuations in quality and quantity of industrial wastes, the greater the advantage in adopting well mixed conditions.

Construction Details:

Lagoons are generally rectangular in shape though it is not absolutely essential. Natural land contours may be followed to the extent possible to save on earthwork.

Construction techniques for aerated lagoons are similar to those used in case of oxidation ponds with earthen embankments. Pitching of the embankment is desirable to protect it against erosion. In cases where soil percolation is expected, suitable lining may have to be provided to maintain the design level in the lagoon and avoid pollution of groundwater.

Substrate Removal Rates:

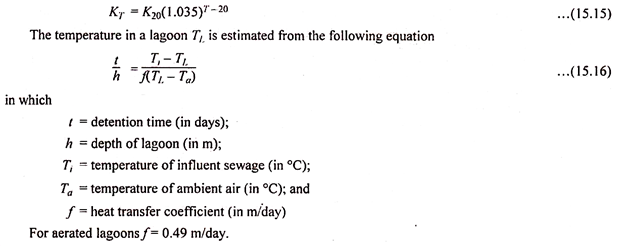

As shown in Table 15.2 for facultative aerated lagoons the overall substrate removal rate constant K for sewage at 20°C, i.e., K20 varies from 0.6 to 0.8 per day (soluble BOD basis). At any other temperature T°C in lagoon the value of K, i.e., KT may be obtained from the following formula-

Sludge Accumulation:

Sludge accumulation occurs at the rate of 0.03 to 0.05 m3 per person per year as in the case of oxidation ponds and is manually removed once in 5 to 10 years and used as good agricultural soil. The depth of the lagoon may be increased a little to allow for sludge accumulation, if desired.

Effluent Characteristics:

The effluent is generally made to flow over an outlet weir. As the concentration of solids passing out in the effluent may be nearly the same as that in the lagoon the BOD corresponding to the volatile fraction of these solids (assumed as 0.77 mg per mg VSS in effluent) should be added to the value of the soluble BOD S obtained by use of equation 15.14 or Fig. 15.14.

Thus the final effluent BOD is given by-

Final BOD mg/l = S mg/l + (0.77) (VSS in effluent) mg/l

It is because of the suspended solids (expected to range from 40 to 60 mg/l in case of domestic sewage) in the final effluent that the total effluent BOD is difficult to reduce below 30 to 40 mg/1 in winter. At other times of the year BOD less than 30 mg/l may be possible.

This range of BOD is more than adequate for irrigation purposes, but for river disposal the applicable standards should be ascertained and design made accordingly. Where necessary, further reduction of BOD can be achieved either by a small increase in detention time or by more efficient interception of solids flowing out (e.g., providing deeper baffle plate ahead of outlet weir) or by provision of an additional treatment unit.

Nitrification is not likely to occur in aerated lagoons. Coliform removal ranges from 60 to 90% and it shows considerable seasonal variation.

9- What are the advantages and disadvantages of oxidation pond?

Advantages

- The stabilization pond can reduce the biological oxygen demand up to 90% naturally.

- Oxidation pond are quite suitable in hot dry countries like india and the places where 200 or more sunny days are expected in a year.

- It is a simple method to operate, does not require sophisticated equipment.

- The biggest advantage of oxidation pond is that it is very cheap & their maintenance cost is minor.

- The operation of a stabilization pond does not require much labour-power.

- It is an economical method for the treatment of wastewater from small and isolated units.

Disadvantages

- The construction of a stabilization pond requires more land area.

- The main disadvantage of oxidation pond is that more nuisance and mosquito breeding takes place.

- It should be located far from residential areas.

- There may get a chance of effluent seepage into the ground water, which can ultimately cause ground water pollution.

Conclusion

Therefore, we can conclude that the oxidation pond is a biological system which takes about 10-40days of detention time. This method can load organic matter up to 300-150Kg/hectare/day and having a length of 50-100m, a width of 30-50m and a depth of 0.9-1.5m.

Usually, an oxidation pond can hold water up to 0.3m and settled sludge up to 0.02m. The decomposition of bio-organics produces a foul smell, that’s why the stabilization pond is kept away from the residential areas. The use of sodium nitrate can avoid foul odour during the wastewater decomposition.

10- Writes down the advantages of root zone cleaning system with its several applications?

Advantages of Root zone System for Treatment of Effluents:

(i) Capital cost involved is comparable or lower depending upon the topography of site and type of soil available.

(ii) Construction of bed is simple and involves no mechanical and electrical equipment.

(iii) System requires little or no maintenance.

(iv) It is a robust process and is able to withstand wide variation of operating conditions.

(v) It gives a consistent quality of treated water.

(vi) It has a potential for bird sanctuary and wildlife habitat.

Major Applications of Root zone System:

(i) Sewage.

(ii) Dairy mill waste.

(iii) Sugar mill waste.

(iv) Food processing/fruit processing.

(v) Petroleum refineries (oil + grease).

(vi) Chemical industries.

(vii) Textile industry.

(viii) Pulp and paper.

(ix) Breweries and distilleries.

(x) Steel plants.

(xi) Coal mines.

(xii) Agrobased industry.

(xiii) Meat and fish processing industry.