UNIT-III

IMPORTANT QUESTIONS

1- Define unit process and unit operation for secondry treatment system with flow diagram?

Unit process includes all the treatment methods in which the removal of contaminants is brought about by chemical or biological reactions. It is considered as a secondary treatment.

While Unit Operation involves only the methods in which physical forces predominates. It is considered as primary treatment.

It removes soluble and colloidal organic matter which remains after primary treatment.

Secondry treatment processes may be classified into-

- Attached growth process

- Suspended growth process

- Combined process

1- Attached growth processes utilize a solid medium such as rock or plastics material upon which bacterial solids are accumulated.

They convert organic matter into gases and cell tissue. Such surface growth processes include-

- Intermittent sand filter

- Trickling filter

- Rotating biological contactors

- Anaerobic lagoons

- Fixed film denitrification

2- Suspended growth processes maintain adequate biological mass in suspension within the liquid in the reactor by employing natural or mechanical mixing.

In most of the processes high solid concentration of solids in maintained by returning bacteria from secondry clarifier. Suspended growth processes include the following-

- Activated sludge process

- Suspended growth nitrification & suspended growth de nitrification

- Aerated lagoons

3- Combined processes include both growth process as well as suspended growth processes. They include following sequence-

- Trickling filter, activated sludge

- Activated sludge, trickling filter

- Facultative lagoons

2- Explain the role of micro organisms present in water?

Wastewater can be detrimental to the environment if left untreated. That’s because waste from humans and pets are a source of several types of waterborne diseases and bacterial contamination.

Thanks in part to microorganisms, treating wastewater and sewage is possible. The role of microorganisms in wastewater treatment helps to treat and purify wastewater and make it less harmful to the environment.

Biological treatment involves the use of different microorganisms present in wastewater such as bacteria , viruses , protozoa.

Here is a list of bacteria used in sewage treatment you can reference.

AEROBIC BACTERIA

Aerobic bacteria are mostly used in new treatment plants in what is known as an aerated environment. This bacterium uses the free oxygen within the water to degrade the pollutants in the wastewater and then converts it into energy that it can use to grow and reproduce. For this type of bacteria to be used correctly, it must have oxygen added mechanically. This will ensure the bacteria are able to do their job correctly and continue to grow and reproduce on its food source.

ANAEROBIC BACTERIA

Anaerobic bacteria are used in wastewater treatment on a normal basis. The main role of these bacteria in sewage treatment is to reduce the volume of sludge and produce methane gas from it.

The great thing about this type of bacteria and why it’s used more frequently than aerobic bacteria is that the methane gas, if cleaned and handled properly, can be used as an alternative energy source. This is a huge benefit considering the already high wastewater treatment energy consumption levels.

Unlike aerobic bacteria, this type of bacteria is able to get more than enough oxygen from its food source and will not require adding oxygen to help do its job. Phosphorus removal from wastewater is another benefit of anaerobic microbes used in sewage treatment.

FACULTATIVE

Facultative microorganisms in sewage treatment are bacteria that can change between aerobic and anaerobic depending on the environment they are in. Note that these bacteria normally prefer to be in an aerobic condition.

Protozoa –

Several types of protozoa are present in wastewater such as amoeba , ciliates ,flagellates etc. the importance of protozoa in wastewater system is maintain a slime layer in the system. They also play a dual role in removing bacteria.Protozoa are removed by the process of dual filtration.

Amoeba are predominant under a young sludge age because they require high nutrient levels or low competition to grow. Under shock loads of biochemical oxygen demand (BOD), high concentrations of particulate matter, toxic conditions, or low dissolved oxygen (DO), amoeba can also dominate.

Flagellates are typically present under a young sludge age as well. Since flagellates compete poorly with bacteria for the same soluble nutrients, their growth is favored at the younger sludge age before bacteria have had a chance to populate. As such, a wastewater sample relatively high in flagellates can indicate high soluble nutrient levels also known as a high food to mass (F:M) ratio.

Ciliates are favored under a healthy sludge age. While they do not consume organic matter, they do feed on bacteria making them excellent indicators of healthy floc formation and useful clarifying agents.

Virus-

Enterovirus and rotavirus are excellent indicators of human facial contamination of wastewater. These viruses are detrimental to humans if they consumed. Diseases such as polio hepatitis as caused by enterovirus while diarrhea are caused by rotavirus. They are removed by ozonation or disinfection.

3- Define activated sludge process & its design procedure?

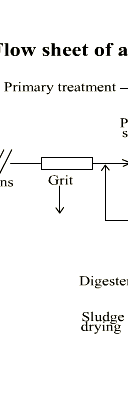

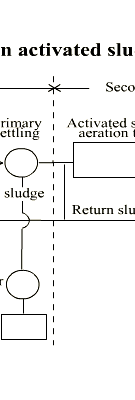

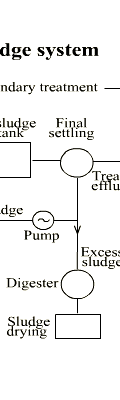

Conventional biological treatment of wastewater under aerobic conditions includes activated sludge process (ASP) and Trickling Filter. The ASP was developed in England in 1914. The activated sludge process consists of an aeration tank, where organic matter is stabilized by the action of bacteria under aeration and a secondary sedimentation tank (SST), where the biological cell mass is separated from the effluent of aeration tank and the settle sludge is recycled partly to the aeration tank and remaining is wasted (Figure ). Recycling is necessary for activated sludge process. The aeration conditions are achieved by the use of diffused or mechanical

Aeration.

Design Consideration

1- Aeration tank loading- the imp terms which deifne the loading rate of ASP.

- Aeration period(HRT)

- BOD loading per unit volume of aeration tank ( volumetric loading)

- Food to microorganism ratio

- Solid retention time (sludge age)

- Sludge volume index

- Hydraulic retention time (HRT) shows the interval when wastewater is maintained in the system in order for being treated. For all three handling solids types, the hydraulic retention time, t, can be determined by t = V/Q, where V represent the volume of the system (m3) and Q is the influent flow-rate (m3 d−1)

- Volumetric loading- The organic matter loading rate applied to the reactor is quantified as kg of BOD applied per unit volume of the reactor per day, called as volumetric loading rate, or kg of BOD applied per day per unit mass of microorganisms present in the reactor (i.e. in the aeration tank), called as organic loading rate . This can be calculated as stated below:

Volumetric loading = Q x BOD x 10-3/ Vol

Where, BOD = Influent BOD5 to aeration tank, mg/L

Q = Flow rate, m3/day

Vol. = Volume of aeration Tank, m3

- F/M ratio-it is an important rational organic loading rate adopted for an activated sludge process. The BOD load applied to the system in kg is represented as food (F) and the total microbial suspended solids in the mixed liquor of the aeration tank is represented by M-

F/M= daily BOD applied to the aerator system in gm/ total microbial mass in the system in gm

, F/M = Q x BOD / (V x Xt)

Where, Xt = MLVSS concentration in the aeration tank, mg/L

The F/M ratio is the main factor controlling BOD removal. Lower F/M values will give higher BOD removal. The F/M can be varied by varying MLVSS concentration in the aeration tank.

- Solid Retention Time (SRT) or Mean Cell Residence Time (MCRT): The performance of the ASP in terms of organic matter removal depends on the duration for which the microbial mass is retained in the system. The retention of the sludge depends on the settling rate of the sludge in the SST. If sludge settles well in the SST proper recirculation of the sludge in aeration tank is possible, this will help in maintaining desired SRT in the system. Otherwise, if the sludge has poor settling properties, it will not settle in the SST and recirculation of the sludge will be difficult and this may reduce the SRT in the system. The SRT can be estimated as stated below:

c = V X

QwXr + (Q-QwXe)

X, Xe and Xr are MLSS concentration in aeration tank, effluent and return sludge respectively, and Qw= waste activated sludge rate.

- Sludge Volume Index: The quantity of the return sludge is determined on volumetric basis. The sludge volume index (SVI) is the volume of the sludge in mL for one gram of dry weight of suspended solids (SS), measured after 30 minutes of settling. The SVI varies from 50 to 150 mL/ g of SS. Lower SVI indicates better settling of sludge. The volume of settled sludge (Vs) is found and Sludge Volume Index (SVI) is calculated from-

S.V.I = (Vs x 1000)/MLSS (ml/g)

4- What do you mean by tapered aeration & step serration in ASP?

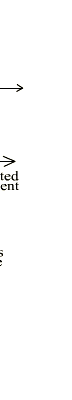

Tapered Aeration

This process involves a very little modification of the conventional process and ensures higher air supply at the inlet and in the initial length of the tank as compared to downstream length .

In plug flow type aeration tank BOD load is maximum at the inlet and it reduces as wastewater moves towards the effluent end. Hence, accordingly in tapered aeration maximum air is applied at the beginning and it is reduced in steps towards end, hence it is called as tapered aeration (Figure). By tapered aeration the efficiency of the aeration unit will be increased and it will also result in overall economy. The F/M ratio and volumetric loading rate of 0.2 to 0.4 kg BOD/kg VSS.d and 0.3 to 0.6 kg BOD/m3.d, respectively, are adopted in design. Other design recommendation are mean cell residence time of 5 to 15 days, MLSS of 1500 to 3000 mg/L, HRT of 4 to 8 h and sludge recirculation ratio of 0.25 to 0.5. Although, the design loading rates are similar to conventional ASP, tapered aeration gives better performance.

No. Of diffuser plates are thus varied accordingly . Such a modification in the conventional activated sludge plant using diffused air aeration has now a days become common feature.

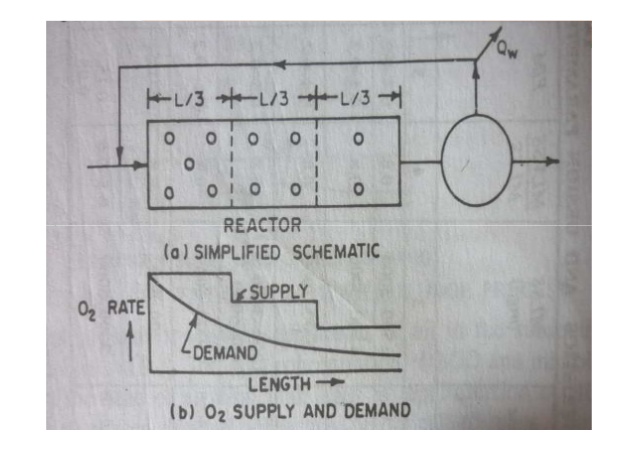

Step aeration

If the sewage is added at more than one point along the aeration channel, the process is called as step aeration (Figure). This will reduce the load on returned sludge. The aeration is uniform throughout the tank. The process enables an appreciable reduction in the aeration tank volume without lowering the BOD removal efficiency . Step aeration method has considerable capacity to absorb shoch organic loadings.The F/M ratio and volumetric loading rate of 0.2 to 0.4 kg BOD/kg VSS.d and 0.6 to 1.0 kg BOD/m3.d, respectively, are adopted in design. Other design recommendation are mean cell residence time of 5 to 15 days, MLSS of 2000 to 3500 mg/L, HRT of 3 to 5 h and sludge recirculation ratio of 0.25 to 0.75. In step aeration the design loading rates are slightly higher than conventional ASP.

5- Explain operational problems occurs in activated sludge sewage treatment plant and its maintenance?

There are two most common difficulties encountered in the operation of activated sludge plant:

1. Rising sludge; and

2. Bulking sludge.

1- rising sludge

Occasionally sludge that has good settling characteristics will be observed to rise or float to the surface after a relatively short settling period. The cause of this phenomenon is denitrification, in which the nitrites and nitrates in the sewage are converted to nitrogen gas. As nitrogen gas is formed in the sludge layers, much of it is trapped in the sludge mass.

If enough gas is formed, the sludge mass becomes buoyant and rises or floats to the surface. Rising sludge can be differentiated from bulking sludge by noting the presence of small gas bubbles attached to the floating solids.

The problem of rising sludge can be overcome by:

(i) by Increasing the rate of return activated sludge pumping from the activated sludge settling tank;

(ii) Decreasing the rate of flow of aeration liquor into the offending tank if the sludge depth cannot be reduced by increasing the return activated sludge withdrawal rate;

(iii) Where possible, increasing the speed of the sludge collecting mechanism in the settling tank and;

(iv) Decreasing the mean cell residence time by increasing the sludge wasting rate.

2-Bulking Sludge:

A bulked sludge is the one that has poor settling characteristics and poor compactability.

Sludge bulking can be caused by

(i) The growth of filamentous organisms (primarily Sphaerotilas) that will not settle, or

(ii) The growth of micro-organisms that incorporate large volumes of water into their cell structure, making their density near that of water and thus causing them not to settle.

The factors which may lead to the development of sludge bulking are:

(a) Inadequate air supply (i.e., under aeration);

(b) Low pH value;

(c) Prolonged detention of sludge in the settling tanks;

(d) Accumulation of sludge at the bottom of the aeration tank;

(e) Sudden change in the character of sewage due to discharge of septic solids from the sewage system;

Highly trained staff is required for maintenance and trouble-shooting. The mechanical equipment (mixers, aerators and pumps) must be constantly maintained. A continuous supply of oxygen and sludge is essential . Control of concentrations of sludge and oxygen levels in the aeration tanks is required and technical appliances (e.g. pH-meter, temperature, oxygen content etc.) need to be maintained carefully. As well, the influent and effluent must be constantly monitored and the control parameters adjusted, if necessary, to avoid abnormalities that could kill the active biomass and the development of detrimental organisms which could impair the process (e.g., filamentous bacteria).

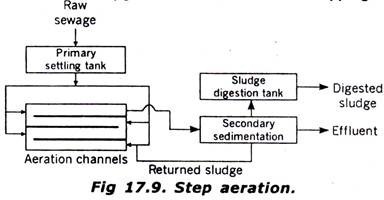

6- Explain the concept of SBR?

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches.

Sequencing Batch Reactor process scheme including the five essential process steps: (1) fill, (2) react, (3) settle, (4 and 5) draw and idle..

The essential components of SBR’s are:

· reactor basin

· waste sludge draw-off mechanism

· aeration equipment

· effluent decanter

· process control system

To accommodate continuous inflow of wastewater, the SBR system generally comprises either a storage / equalization tank and a single SBR tank or a minimum of two tanks. As with conventional activated sludge treatment systems, conventional screening and grit removal are usually provided as preliminary treatment. A primary sedimentation stage is not usually required with SBR processes unless the influent suspended solids are excessive. Settled sewage may also be treated if the SBR is installed downstream of existing primary settlement tanks. Reactors are usually simple circular, square or rectangular tanks and may be constructed from concrete or steel. Lagoon structures can also be used and existing tanks, for example, primary sedimentation tanks, can be retrofitted. Since the tank serves as an aeration tank and a final clarifier, fewer structures are used for the treatment plant as a whole and a more compact layout for the site can be obtained. Extensions to the plant by the addition of modular basins using common wall construction can easily be designed for future loading conditions.

The main advantage of sequencing batch reactors is that they produce effluent low in organic compounds and thus can be used to meet strict effluent standards. The system can be effectively used as part of a larger system when the removal of the nutrients nitrogen and phosphorus are required. Other advantages are that it can be located on a small area of land, and it is relatively easy to expand this system by adding additional reactors. However, the operation of this system is more complex than others. The system does tend to be more costly to construct and operate than most others, yet it usually has fewer maintenance problems over its lifetime.

7- What is the principle of trickling filter & design standard for standard rate trickling filter?

BIOLOGICAL PRINICPLE-

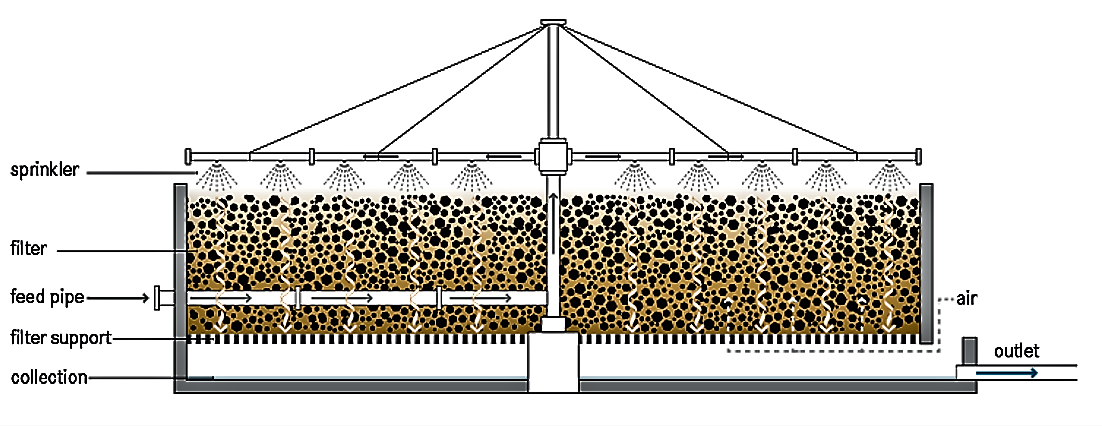

A trickling filter is a type of wastewater treatment system. It consists of a fixed bed of rocks, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flows downward and causes a layer of microbial slime (biofilm) to grow, covering the bed of media. Aerobic conditions are maintained by splashing, diffusion, and either by forced-air flowing through the bed or natural convection of air if the filter medium is porous.

The terms trickle filter, trickling biofilter, biofilter, biological filter and biological trickling filter are often used to refer to a trickling filter. These systems have also been described as roughing filters, intermittent filters, packed media bed filters, alternative septic systems, percolating filters, attached growth processes, and fixed film processes.

The settled sewage from primary sedimentation tank is sprinkled intermittently over the filter bed when sewage trickles down, a microbial layer develops on the surface of rock which is called slime layer which is mostly consist of bacteria. (Oxidation of the organic matter is carried out under aerobic conditions. A bacterial film is formed around the particles of the filtering media and for the existence of this film oxygen is supplied by the intermittent working of the filter and by the provision of the suitable ventilation facilities in the body of the filter). The sewage is oxidized by the bacteria producing effluent in the form of water, gases and new cells.

Trickling filter media & their characteristics-

The filtering media consists of coarser materials like cubically broken stones or slag free from dust and small pieces . The size of material used may vary between 25 to 75mm . the filtering material should be washed before it placed in position . The quality of stones used should be such as not to be easily affected by acidic sewage and should be sufficiently hard and should have minimum compressive strength of about 100 N/mm2 . Its resistence to freezing and thawing is an another important property .

The depth of filtering media may vary between 2 to 3 m . The filtering material should be placed in layers with coarsest stone used near the bottom and finer material towards the top.

Filter media should have

- High specific surface area

- High percent void space

- Resistance to abrasion and disintegration during placement

- Insolubility in sewage or wastewater

- Resistance to spalling or flaking

- Filtering media should be round or cubical in shape

Property desired value

Crushing strength not less than 100 N/mm2

Hardness not less than 12

Percent wear not more than 4

Specific gravity not less than 2.6

Design of standard rate trickling filter-

1- Hydraulic loading-

It is the ratio of discharge to the surface area. The value of hydraulic loading rate for standard filter may vary between 22 to 44 million liter per hectare per day .

Unit-millionlitre/hect/day

2- Organic loading- it is expressed in kg of BOD5 per hectare metre of the filter media per day . the value of organic loading for standard filter may vary between 900 to 220 kg of BOD5 of sewage entering the filter per day

Ratio of BOD load to the volume of filter media.

Organic loading= Q* BOD5/V

It may also be mentioned that the filter dia and depth designed for average value of sewage flow.

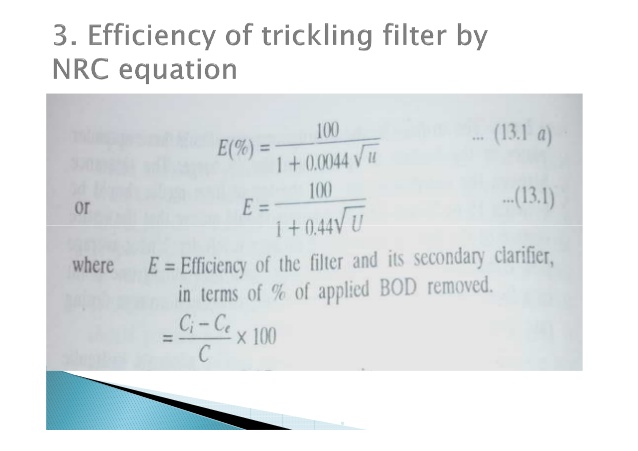

3- Efficiency of trickling filter by NRC eqn-

The effluent obtained from trickling filter is highly nitrified and stabilized . The BOD is reduced to about 80 to 90 % of original value. The BOD left in the effluent generally less than 20ppm .

8- Define recirculation and design steps for high rate trickling filter?

Design of high rate trickling filter-

1- Hydraulic loading-

It is the ratio of discharge to the surface area. The value of hydraulic loading rate for standard filter may vary between 110 to 330 million liter per hectare per day .

Unit-millionlitre/hect/day

2- Organic loading- it is expressed in kg of BOD5 per hectare metre of the filter media per day . the value of organic loading for standard filter may vary between 6000 to 18000 kg of BOD5 of sewage entering the filter per day

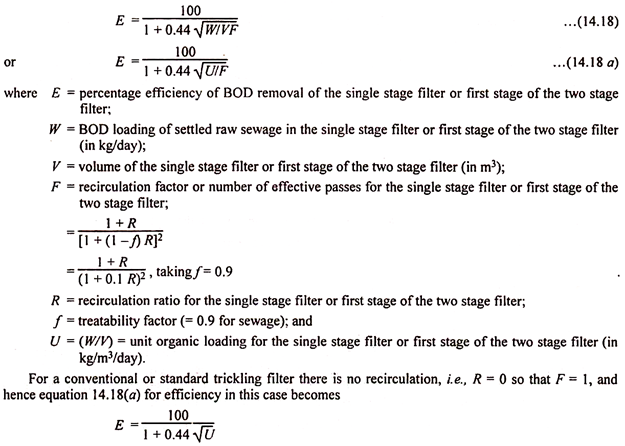

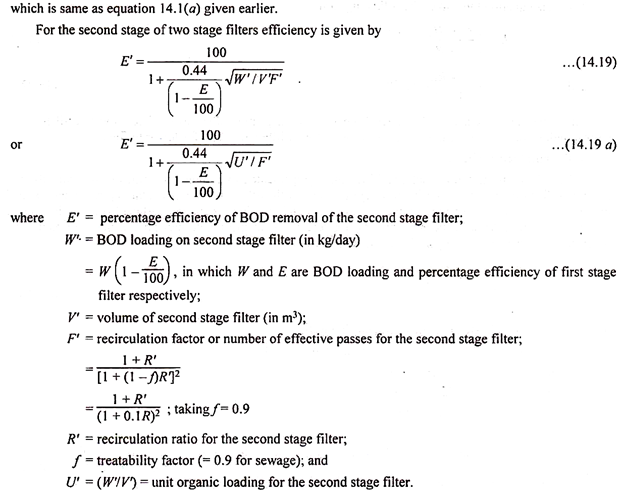

Organic loading rate and recirculation ratio are main consideration in design of trickling filter. The early performance equations for trickling filter were empirical as proposed by National Research Council (1946), Rankine (1955) and based on biochemical kinetics Velz (1948).

The NRC equations for trickling filter performance are empirical expressions developed from a study of the operation results of trickling filters serving military installations in USA. These equations are applicable to both low-rate as well as high-rate filters. The efficiency of single stage filter or first stage of two stage filters is given by-

Recirculation-

In high rate trickling filter the effluent is again sprinkled over the filter media, which is known as recirculation.

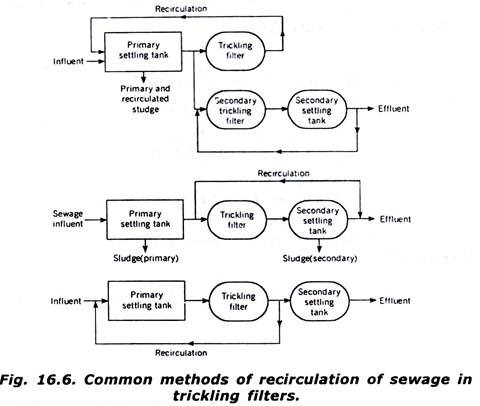

Fig. 16.6 illustrates the line diagrams of some of the common methods of recirculation of sewage effluent.

9- Write down the operational problems induced in the filters and their control measures?

Operational problems in trickling filter-

1. Filter Ponding

If the voids in the media get plugged, flow can collect on the surface in ponds. Excessive sloughing, excessive organic loading, non-uniformity in size of media and improper functioning of primary treatment units are its chief causes.Remedies

- Wash the filter surface with a stream of water under high pressure.

- Dose the filter with heavy applications of chlorine.

- Take the filter out of service for a period of one day or longer to allow it to dry out.

2. Filter Flies

Primary nuisance insect- tiny, gnat-size filter fly, or Psychoda. Filter flies develop most frequently in an alternately wet and dry environment. Remedies:

- Dose filter continuously, not intermittently.

- Keep orifice openings clear

- Apply insecticides to filter walls

- Dose filter with chlorine

- Keep weeds and tall grass cut around filter

3. Odours

The presence of “rotten egg” odour is an indication of anaerobic condition.Remedies

- Maintain aerobic conditions in all units, including settling tanks and waste water system.

- Recirculate to filters.

4. Icing for Filter Surface

Cold weather not only reduces the efficiency of trickling filters by decreasing the activity of the microorganisms, but in severe cases actually can cause the wastewater to freeze on the medium surface.Remedies

- Decrease recirculation to the filter (influent is usually warmer than recycled flows)

- Construct wind screens

- Operate two-stage filters in parallel rather than in series

Control measures-

There are various control measures in trickling filter-

1- increase hydraulic loading to wash out excess biological growth, remove debris from filter effluent channels, install fans to induce draft through filters.

2- Reduce loading : increase BOD removal in primary settling tanks: enhance aerobic conditions in treatment channels by adding chemical oxidants, pre aerating , increasing air to aerated grit chambers, use plastic media instead of rock.

3- Increase hydraulic loading to increase sloughing: use high pressure stream of water to flush filter surface, maintain 1-2 mg/l residual chlorine on the filter for several hours.

4- Decrease recirculation :use high pressure stream water to remove ice from orifices , nozzles and distributor arms :reduce number of filters in service as long as effluents limits can still be met: reduce retention time in pre treatment and primary treatment units.

5- Remove material from vent pipe by rodding or flushing.

Flush out arms by opening end plates, remove solids from wastewater.

10 -Explain the principle and working of RBC ( rotating biological contactor)?

The RBC method of secondry wastewater treatment has been recently developed and does not fit precisely in to either the trickling filter or activated sludge categories, but does employ principle common to both of them.

The RBC is a cylindrical media made of closely mounted thin flat circular disc of 3 to 3.5m in diameter, 10mm thick and are placed at 30 to 40mm spacing mounted on a common shaft . Thinner materials can be used by sandwiching a corrugated sheet between two flat discs and welding them together as a unit.

The RBC are usually made in up to 8m length and may be placed in series or parallel in a specially constructed tank through which the waste water is allowed to pass .The RBC are kept immersed in water by about 40% of their diameter. The RBC are rotated around their central horizontal shaft at a speed of 1-2 rpm by means of power supplied to the shaft.

The hydraulic loading rate may vary between 0.04 to 0.06 m/day and organic loading rate between 0.05 to 0.06 kg of BOD5 applied per day

.

Fig RBC

Secondary Biological Treatment Activated Sludge Process: Consists of aeration tank plus secondary sedimentation tank. It is mainly to remove BOD5 (i.e., organic compounds) and SS. The purpose of the return of activated sludge is to maintain a sufficient concentration of activated sludge in the aeration tank. Trickling Filters: It is a bed of media (e.g., rocks) over which wastewater is continuously distributed. The spaces between the rocks allow air to circulate easily so that aerobic condition can be maintained. Nowadays, plastic media are becoming increasingly popular as a replacement for rocks because of the heavy weight of rocks. Rotating Biological Contactor: RBC consists of a series of closely spaced, circular, plastic disks. The bottom 40% of each disk is submersed in a tank with a wastewater to be treated.