UNIT-II

IMPORTANT QUESTIONS

1- What do you mean by pollution due to improper disposal of sewage?

There is a lot of sewage flowing around due to a poor drainage system especially in the areas around River in india. We need to look at this problem squarely and find solutions before the health and hygiene of the people living in these areas suffer from diseases associated with this rot.

Sanitation is the worst problem facing the city, which needs to be addressed properly and energetically, otherwise soon or later, we are at risk of an outbreak of water born diseases.

If hygiene is in question and vaccines and treatment ineffective or too expensive, then how can we reduce high mortality and morbidity rates due to infectious diseases

While there have been excellent views on the indiscriminate spiting and urinating in the public places, none has so far addressed the practical consequences for hygiene, whether trends in increased infection justify continued silent on sewage in our city.

When toxic substances enter a body of water, they will be dissolved, become suspended in water or get deposited on the bed of the water body.

The resulting water pollution causes the quality of the water to deteriorate and affects aquatic ecosystems. Pollutants can also seep down and effect groundwater deposits. Sewage and industrial wastes are discharged into the rivers. Because of this, pollutants enter groundwater, rivers, and other water bodies.

Such water, which ultimately ends up in our households, is often highly contaminated and can carry disease-causing microbes.

Domestic sewage contains a wide variety of dissolved and suspended impurities. It amounts to a very small fraction of the sewage by weight, but it is large by volume and contains impurities such as organic materials and plant nutrients that tend to rot.

1- Ecological Damage:

Sewage-contaminated water causes eutrophication, which is the increase in concentration of chemical elements required for life. The nitrates, phosphates, and organic matter found in human waste serve as food for algae and bacteria

This causes these organisms to overpopulate to the point where they use up most of the dissolved oxygen that is naturally found in water, making it difficult for other organisms in this aquatic environment to live. The bacteria are basically strangling the other organisms.

2-Health Risks:

A variety of organisms live in the human gastrointestinal tract. These organisms including bacteria, viruses, and parasites, end up in human waste. Many of these organisms can be transmitted to other humans and animals.

Bathers are at increased risk of contracting illness due to bacteria and viruses present in sewage effluent. Gastrointestinal disorders have been linked to sewage pollution, with viruses implicated as the cause. Shellfish strain water through their gills to trap microscopic plants and animals for food.

If the water was contaminated with disease-causing bacteria, these could be consumed as food by shellfish. When eaten raw or partially cooked, these shellfish can make people sick.

Certain fish in contaminated waters can accumulate high levels of toxic substances. When these foods are consumed frequently over a lifetime, they may increase the consumers’ risk of adverse health effects. Detergents can cause liver and kidney damage, while sewage water carries diseases such as Giardiasis, Amoebic dysentery and Cholera.

2- Explain primary and secondry treatment of sewage?

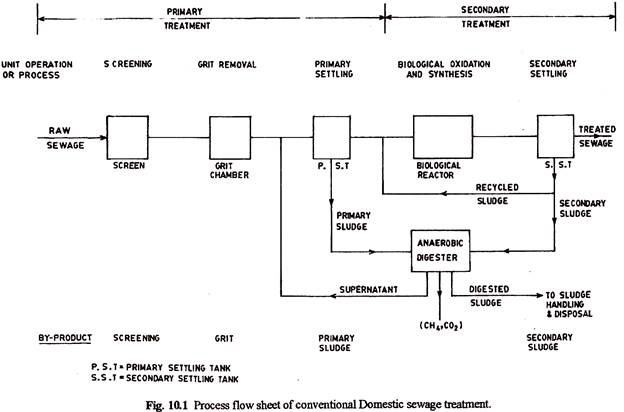

The primary treatment consists in removing large suspended organic solids from the wastewater. They are also referred as the physical unit operations. The unit operations used are screening for removing floating papers, rages, cloths, plastics, cans stoppers, labels, etc.; grit chambers or detritus tanks for removing grit and sand; skimming tanks for removing oils and grease; and primary settling tank for removal of residual settleable suspended matter.

Screen is the first unit operation carried out in wastewater treatment plant. This is used to remove larger particles of floating and suspended matter by coarse screening. This is accomplished by a set of inclined parallel bars, fixed at certain distance apart in a channel. The screen can be of circular or rectangular opening. The screen composed of parallel bars or rods is called a rack. The screens are used to protect pumps, valves, pipelines, and other appurtenances from damage or clogging by rags and large objects.

Secondary treatment removes the soluble organic matter that escapes primary treatment. It also removes more of the suspended solids. Removal is usually accomplished by biological processes in which microbes consume the organic impurities as food, converting them into carbon dioxide, water, and energy for their own growth and reproduction.

It involves further treatment of the effluent coming from the primary sedimentation tank. This is generally accomplished through biological decomposition of organic matter which can be carried out under aerobic as well as anaerobic conditions.

The treatment reactors in which the organic matter is oxidized by aerobic bacteria are known as aerobic biological units and may consists of –

1- Trickling filters

2- Aeration tanks with the feed of recycled activated sludge

3- Oxidation ponds and aerated lagoons

The treatment units in which the organic matter is destroyed by anaerobic bacteria are known as anaerobic biological units and may consists of septic and imhof tanks.

Trickling filter-

A trickling filter is simply a tank filled with a deep bed of stones. Settled sewage is sprayed continuously over the top of the stones and trickles to the bottom, where it is collected for further treatment. As the wastewater trickles down, bacteria gather and multiply on the stones. The steady flow of sewage over these growths allows the microbes to absorb the dissolved organics, thus lowering the biochemical oxygen demand (BOD) of the sewage. Air circulating upward through the spaces among the stones provides sufficient oxygen for the metabolic processes.

Settling tanks, called secondary clarifiers, follow the trickling filters. These clarifiers remove microbes that are washed off the rocks by the flow of wastewater. Two or more trickling filters may be connected in series, and sewage can be recirculated in order to increase treatment efficiencies.

Activated sludge-

The activated sludge treatment system consists of an aeration tank followed by a secondary clarifier. Settled sewage, mixed with fresh sludge that is recirculated from the secondary clarifier, is introduced into the aeration tank. Compressed air is then injected into the mixture through porous diffusers located at the bottom of the tank. As it bubbles to the surface, the diffused air provides oxygen and a rapid mixing action. Air can also be added by the churning action of mechanical propeller-like mixers located at the tank surface.

Rotating biological contacter-

In this treatment system a series of large plastic disks mounted on a horizontal shaft are partially submerged in primary effluent. As the shaft rotates, the disks are exposed alternately to air and wastewater, allowing a layer of bacteria to grow on the disks and to metabolize the organics in the wastewater.

3- What in unit process and unit operation and flow diagram of physical and chemical unit processes?

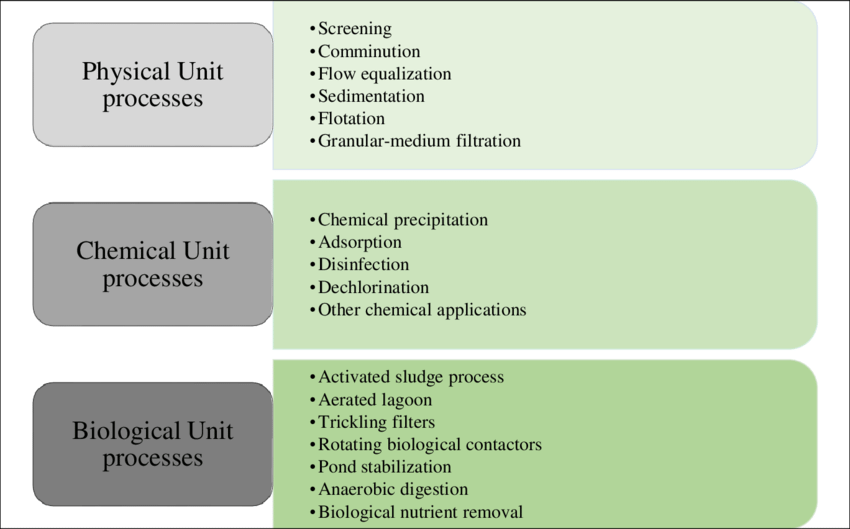

Waste water treatment in any unit operation or process can reduce the objectionable properties of waste water and render it less dangerous.

Waste water treatment is a combination of physical , chemical and biological process. Methods of treatment in which application of physical forces predominate are known as unit operation.

Method of treatment in which chemical or biological process are involved known as unit processes.

4- Define screen & its types & what are its design requirements?

Screen is the first unit operation carried out in wastewater treatment plant. This is used to remove larger particles of floating and suspended matter by coarse screening. This is accomplished by a set of inclined parallel bars, fixed at certain distance apart in a channel. The screen can be of circular or rectangular opening. The screen composed of parallel bars or rods is called a rack. The screens are used to protect pumps, valves, pipelines, and other appurtenances from damage or clogging by rags and large objects.

Types of Screens

Screens can be broadly classified depending upon the opening size provided as coarse screen (bar screens) and fine screens. Based on the cleaning operation they are classified as manually cleaned screens or mechanically cleaned screens. Due to need of more and more compact treatment facilities many advancement in the screen design are coming up.

1- Coarse screen-

It is used primarily as protective device and hence used as first treatment unit. Common type of these screens are bar racks (or bar screen), coarse woven-wire screens, and comminutors.Bar screens are used ahead of the pumps and grit removal facility. This screen can be manually cleaned or mechanically cleaned. Manually cleaned screens are used in small treatment plants. Clear spacing between the bars in these screens may be in the range of 15 mm to 40 mm.

2- Fine screen-

Fine screens are mechanically cleaned screens using perforated plates, woven wire cloths, or very closely spaced bars with clear openings of less than 20 mm, less than 6 mm typical. Commonly these are available in the opening size ranging from 0.035 to 6 mm. Fine screens are used for pretreatment of industrial wastewaters and are not suitable for sewage due to clogging problems, but can be used after coarse screening. Fine screens are also used to remove solids from primary effluent to reduce clogging problem of trickling filters. Various types of microscreens have been developed that are used to upgrade effluent quality from secondary treatment plant. Fine screen can be fixed or static wedge-wire type, drum type, step type and centrifugal screens. Fixed or static screens are permanently set in vertical, inclined, or horizontal position and must be cleaned by rakes, teeth or brushes. Movable screens are cleaned continuously while in operation. Centrifugal screens utilize the rotating screens that separate effluent and solids are concentrated.

5- Design a grit chamber for population 50000 with water consumption of 135 LPCD?

Average quantity of sewage, considering sewage generation 80% of water supply, is

= 135 x 50000 x 0.8 = 5400 m3/day = 0.0625 m3/sec

Maximum flow = 2.5 x average flow

= 0.0625 x 2.5 = 0.156 m3/sec

Keeping the horizontal velocity as 0.2 m/sec (<0.228 m/sec) and detention time period as one

Minute.

Length of the grit chamber = velocity x detention time

= 0.2 x 60 = 12.0 m

Volume of the grit chamber = Discharge x detention time

= 0.156 x 60 = 9.36 m3

Cross section area of flow ‘A’ = Volume / Length = 9.36/12 = 0.777 m2

Provide width of the chamber = 1.0 m, hence depth = 0.777 m

Provide 25% additional length to accommodate inlet and outlet zones.

Hence, the length of the grit chamber = 12 x 1.25 = 15.0 m

Provide 0.3 m free board and 0.25 m grit accumulation zone depth, hence total depth

= 0.777 + 0.3 + 0.25 = 1.33 m

And width = 1.0 m

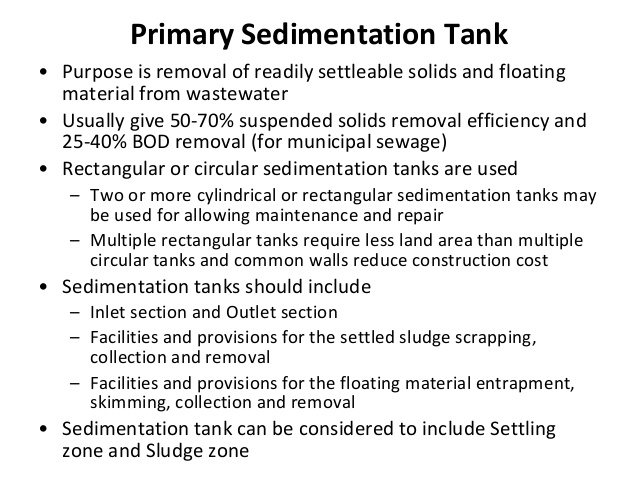

6- Define primary sedimentation tank and what are the design specifications of PST?

Design Specifications of Primary Sedimentation Tank

1. Hydraulic loading rate (surface overflow rate)/settling velocity Vs = (0.3 – 0.7) mm/sec (1 – 2.5 m/hr)

2. Detention time / retention time Td = 1 – 2 hrs

3. Depth of Tank = (1 – 5) m

4. BOD removal (20 – 40) %

5. Suspended solids removal (30 – 60) %

6. Minimum number of tanks = 2

7. Sludge accumulated = 2.5 Kg of wet solids / m3 of flow.

7- Design the primary sedimentation tank to treat wastewater with average flow rate of 10 MLD and peak flow of 22.5 MLD?

Assume surface settling rate = 40 m3/m2.d

Therefore, the surface area of the tank = 10 x 106 / 40 x 103 = 250 m2

Check for peak flow condition: The SOR at peak flow = 22.5 x 103 /250 = 90 m3/m2.d

This is less than the recommended value at peak flow.

Assume width = 6.0 m

Therefore theoretical length = 250/6 = 41.66 > 40 m

Hence, provide two tanks in parallel

Total length of each tank = 41.66/2 + 2 (inlet) + 2 (outlet) = 24.83 say 24.85 m

Now,

Flow rate x detention time = depth x surface area = volume of tank

Or Flow / Surface area = depth / detention time = Surface settling rate

Provide detention time of 1.5 h

Therefore, liquid depth required = 40 x 1.5 / 24 = 2.5 m

Therefore, flow through velocity = (0.116 m3/sec) / (2 x 2.5 x 6)

= 0.0039 m/sec < 1 cm/sec hence O.K.

At peak flow, the flow through velocity = 22.5 x 103 /(2 x 6 x 2.5) = 750 m/d = 0.0087 m/sec.

(Horizontal velocity should be checked for non-scouring velocity i.e. less than 0.06 m/sec.)

Provide total depth = 2.5 + 0.5 (free board) + 0.25 (space for sludge) = 3.25 m

Weir loading rate = 10 x 103 / 12 = 833.33 m3/m.day > 185 m3/m.day

Length of weir required = 10 x 103 / 185 = 54.05 m

Hence, provide about 27.1 m of weir length for each tank. This can be provided by two effluent collection channels across the width at outlet end offering total 24.0 m and side weir of total 1.55 m on each side.

8- Write down the design requirements of grit chamber ?

Grit chamber is a long narrow or circular tank in the primary sewage treatment plant that is designed to reduce the velocity of the flow of sewage to eliminate the girt materials such as sand, ash and clinkers, eggshells, bone chips and many inert materials inorganic in nature.

The various considerations involved in the design of grit chambers are as follows: 1. Settling Velocity 2. Surface Overflow Rate (SOR) 3. Detention Period 4. Bottom Scour and Flow through Velocity 5. Velocity Control Devices

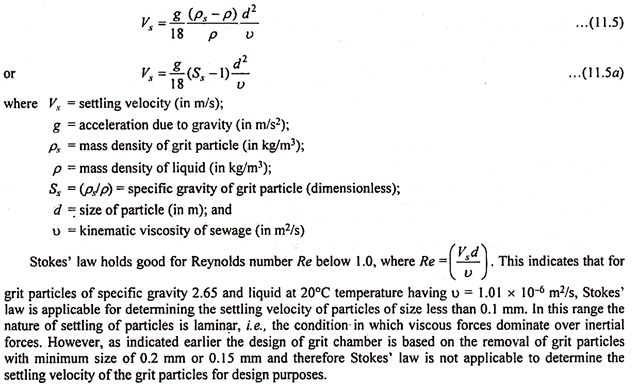

1. Settling Velocity:

Grit chamber may be designed on a rational basis by considering it as a sedimentation basin. The grit particles are treated as discrete particles settling with their own settling velocities. The settling velocity is governed by the size and specific gravity of the grit particles to be separated and the viscosity of the sewage.

The minimum size of grit to be removed is 0.2 mm although 0.15 mm is preferred for conditions where considerable amount of ash is likely to be carried in the sewage. The specific gravity of girt may be as low as 2.4 but for design purposes a value of 2.65 is used.

The settling velocity of discrete particles can be determined using the appropriate equation depending upon the Reynolds number as indicated below:

(a) Stokes’ Law:

The settling velocity of discrete particles is given by Stokes’ law as-

2. Surface Overflow Rate (SOR):

Grit chambers are basically settling tanks. The efficiency of an ideal grit chamber or settling tank is expressed as the ratio of the settling velocity (Vs) of the particles to be removed to the surface overflow rate (V0), i.e.,

3. Detention Period:

The detention period for grit chambers may vary from 45 to 90 seconds. A detention period of 60 seconds is usually adopted in the design of grit chambers.

4. Bottom Scour and Flow through Velocity:

The efficiency of grit chamber is very much affected by bottom scour. The scouring process itself determines the optimum velocity of flow through the grit chamber. This may be explained by the fact that there is a critical velocity of flow Vc beyond which particles of a certain size and density once settled may be again set in motion and reintroduced into the stream of flow. The critical velocity for scour may be calculated from modified Shield’s formula-

Where Kc = 3 to 4.5. A value of 4 is usually adopted for grit particles.

For a grit particle size of 0.2 mm, the formula gives critical velocity values of 17.1 to 25.6 cm/s. In actual practice, a horizontal velocity of flow of 15 to 30 cm/s is used at peak flows. The horizontal velocity of flow should be maintained constant at other flow rates also to ensure that only organic solids and not the grit are scoured from the bottom.

9- Explain tertiary treatment of sewage of removal of solids present in the sewage?

The treatment is sometimes called final treatment and consists of removing organic load left after secondry treatment and to kill pathogenic bacteria, which is normally carried out by chlorination . The removal of suspended and dissolved solids in this process is 100% and BOD is 100%.

The sewage treatment is therefore usually confined up to secondry treatment only .

The Filtration Building contains a series of sand filters that are 27 feet tall, and can filter almost 14,000 gallons of water per hour. The filters remove very tiny solids (“suspended solids”) from the wastewater before it moves on to disinfection. Polymers are added at this step to cause the suspended solids to clump together, making them easier to filter out.

Membrane process-

Membrane technology is used to treat a variety of wastes including sewage, organic and inorganic matter and water-soluble oil wastes. The membrane processes are classified on the basis of driving force and separation mechanism such as Multi Filtration (MF), Ultrafiltration (UF), Nano filtration (NF), Reverse Osmosis (RO), and Forward Osmosis (FO)

Tertiary treatment may be provided to the secondary effluent for one or more of the following contaminant further.

To remove total suspended solids and organic matter those are present in effluents after secondary treatment.

To remove specific organic and inorganic constituents from industrial effluent to make it suitable for reuse.

To make treated wastewater suitable for land application purpose or directly discharge it into the water bodies like rivers, lakes, etc. To remove residual nutrients beyond what can be accomplished by earlier treatment methods.

To remove pathogens from the secondary treated effluents.

To reduce total dissolved solids (TDS) from the secondary treated effluent to meet reuse quality standards.