UNIT-V

IMPORTANT QUESTIONS

1- Define principle of septic tank & up flow anaerobic filter?

This is basically a sedimentation tank with some degree of solid destruction due to sedimentation and subsequent anaerobic digestion. Septic tanks have longer detention period of about 12 to 36 hours with extra provisions of digested and settled sludge .the septic tank units are generally classified under units which works on the principle of anaerobic decomposition . Septic tanks can be made from concrete, masonry or fiberglass. Prior two are of rectangular shape and later is generally of circular shape. The inlet and outlet are baffled so that the floating matter and grease will be retained in the tank. A septic tank is thus a continuous flow type sedimentation tank directly admitting raw sewage and removing 60 to 70 % of dissolved matter in it. The effluent obtained from septic tank will be foul in nature and will have to be disposed of either sub surface irrigation or in cess pools or soak pits . Every septic tank should be provided with the ventilation pipe with the top of the pipe covered with suitable mosquito proof wire mesh. The top of the pipe should extend to at least 2 m above the highest building height present in the vicinity of 20 m from the septic tank.

The sludge settled at the bottom of the tank are allowed to remain in the tank for a period of several months .

The ratio of peak flow to average flow may be very high for the small septic tanks, and can disturb the functioning of the tank due to flow surges, leading to washout of the settled solids. The liquid depth of the tank is 1 to 2 m and the length to the width ratio is in the range of 2:1 to 4:1.

The sludge accumulated in the tank is cleaned at the frequency of once in 2 to 3 years. Minimum of 300 mm of free board should be provided in the tank. The effluent of the septic tank is offensive and potentially dangerous. Hence, further treatment for septic tank effluent is necessary to protect the receiving environment. Due to inadequate treatment offered to the sewage, septic tanks are recommended for individual houses and for cluster of houses or institutes where contributing population is not exceeding 300 persons.

Average flow per capita 100 - 160 L/day

Peak flow per capita 170 - 270 L/day

BOD per capita 0.045 kg/day

Suspended solids per capita 0.070 – 0.090 kg/day

Soluble solids per capita 0.035 kg/day

Sludge accumulation per capita 0.073 m3/year

The septic tanks are generally provided in the areas where sewer have not been laid and for catering to the sanitary disposal of sewage produced from schools , hospitals, hotels etc.

Up flow anaerobic filter-

An anaerobic filter is a fixed-bed biological reactor with one or more filtration chambers in series. These are operated under submerged conditions. In such a filter , the septic tank effluent is introduced from the bottom and microbial growth ,in retained on the stone media the anaerobic filters are single and double chambered . In single chambered up flow tank the chamber is packed with coarse material and the size of packing media should be 20mm . the stone media rests on the concrete slab . The effluent from the septic tank enters the bottom of filter chamber through 150mm dia pipe and is distributed upward through the media with a perforated slab. In double chambered filter the filter consists of two inter connected compartments . The first chamber is filled to a depth of 0.55m with 20mm coarse medium and the second chamber is filled to a depth 0.45m with 20mm size aggregates.

In this filter a crushed rock of 15-25mm size or plastic bags are packed in a closed tank, and the waste water in entered to the bottom and move up the packing media. The sludge in entrapped n the void space between the packing material.

A number of such filters has been constructed for treatment of low strength municipal waste water 65 to 75% efficiency in removal of BOD.

2- What is packaged sewage treatment plant & explain its working?

Packaged Sewage Treatment Plant (PSTP) is housed in specially designed and highly durable FRP tank. These tanks are compact which can be utilized in a decentralized manner at any location, either it’s underground or above the ground.

The major components of a package sewage treatment plant are:

I) Inlet works

a) Primary screen.

b) Pump Station (if applicable).

c) Secondary screen.

d) Grit and grease chambers.

II) Biological treatment system

a) Balancing Tank.

b) Aeration/Anoxic Tank.

c) Clarifier.

d) Sludge Holding Tank.

e) Aeration System including blower house.

f) Sludge Dewatering System.

III) Outlet works

a) Disinfection that can be physical, chemical or radiation

Appurtenances used in STP-

1- Piping system-

a) The piping used shall be an approved product, supplied and manufactured by a supplier/manufacturer approved by the Commission and shall be suitable for the application.

b) The arrangement of the piping system and interconnection pipes in the tanks shall not obstruct maintenance work of the equipment in the tanks.

c) All the buried piping shall be properly bedded and supported with the selected compacted fill material.

d) All the above ground piping shall have a minimum distance of 75 mm from the ground level.

e) It shall be provided with a proper pipe support and bracket. The bracket shall be made of hot dipped galvanised steel.

2- diffuser-

a) All diffusers must be supported from the tank base.

b) The diffuser shall not be bolted to the bottom of the tank.

c) The diffuser shall be removable and easy to re-install.

3- flow distribution chamber-

a) Distribution box shall be provided with adjustable features.

b) The design and construction of the distribution chamber shall prevent any sedimentation.

4- Anchor System Loading

The tank anchor system (straps, cables, turnbuckles, etc.) shall have strength of at least 1.5 times the maximum uplift force of an empty tank without backfill in place. All wire straps, cables and turnbuckles must be made of Grade 304 stainless steel.

3- Write down the advantages and disadvantages of PSTP(packaged sewage treatment plant)?

Advantages of packed sewage treatment plant-

- In decentralized treatment system, sewage treatment system can be obtained by providing colony wise / sector-wise treatment system.

- Responsibility of construction as well as O & M may be taken up by the residential colonies, builders- developers.

- Compact Package plant is simple to operate.

- It is mostly based on gravity and requires very less energy.

- It requires minimum maintenance, land & consumables for reducing operating cost.

DisAdvantages of packed sewage treatment plant-

- Management system of any city consists of collection, treatment and disposal.

- Depth of sewer increases with increase of length of sewer line.

- Pumping of sewage at the intermediate and terminal points requires a lot of energy.

- Very large volume of sewage & also distance of conveyance, to the STP which are generally located outside of the cities, is long

4- Comparison between MBR & MBBR?

Membrane bioreactor (MBR) is the combination of a membrane process like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. It is now widely used for municipal and industrial wastewater treatment. Membrane bioreactor (MBR) technology has emerged as a wastewater treatment technology of choice over the activated sludge process (ASP), which has been the conventional municipal wastewater technology over the last century.

An MBR is a hybrid of a conventional biological treatment system and physical liquid–solid separation using membrane filtration in one system. The MBR technology provides the following advantages over ASP: High-quality effluent, higher volumetric loading rates, shorter hydraulic retention times (HRT), longer solid retention times (SRT), less sludge production, etc.

It is possible to operate MBR processes at higher mixed liquor suspended solids (MLSS) concentrations compared to conventional settlement separation systems, thus reducing the reactor volume to achieve the same loading rate.

Two MBR configurations exist: internal/submerged, where the membranes are immersed in and integral to the biological reactor; and external/sidestream, where membranes are a separate unit process requiring an intermediate pumping step.

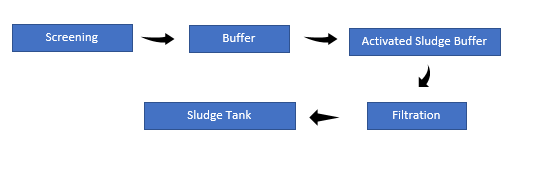

The MBR flow chart is-

MBBR(Moving bed bio reactor)-

Moving bed biofilm reactor (MBBR) is a biological technology used for wastewater treatment process suitable for municipal and industrial application. Another common name is moving bed film reactor. It was invented in the 1980s. MBBR offer an economical solution for wastewater treatment. STP MBBR technology is the use of a moving bed biofilm reactor in sewage treatment plants.

MBBR wastewater treatment system enables efficient results of the disposal using low energy. The technology is used to separate organic substances, nitrification and denitrification. MBBR design is made of an activated sludge aeration system. The sludge is collected on the plastic carriers which have a large internal surface area. The surface area in the carriers optimizes the contact of water, air, and the bacteria.

There are several benefits of MBBR-

- Saving of space due to its compactness

- Easy to maintain

- Good for a high volume of load

- Lower discharge costs

- MBBR is not affected by toxic shock

- It has high effectiveness of sludge retention time (SRT) which enhances the nitrification process

- Production of sludge is lower

- It does not need recycling of the sludge-like activated sludge system

- MBBR media is installed to retrofit existing activated sludge tanks in order to increase its capacity

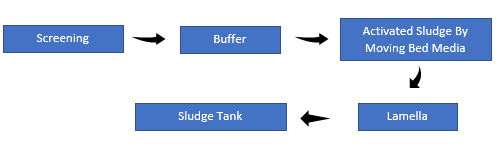

The MBBR flow chart is shown in fig below-

5- Write down the working principle of FMBR with its flow diagram?

FMBR(fixed bed reactor)-

The facultative membrane bioreactor (FMBR) is a biological wastewater treatment process that removes carbon, nitrogen and phosphorus simultaneously in a single reactor. It encourages a natural microbial competition, maximizes activity of the mixed biomass consortium, saves energy, and meets nutrient discharge limits with simple controls. It is a breakthrough technology for the utility of the future that enables simultaneous removal of C, N, and P, reduces operating costs with less carbon emission, and requires only very low periodic bio sludge wasting.

Characteristics of FMBR

- Simultaneous removal of organic carbon, nitrogen and phosphorus

- Requires only very low periodic biosludge wasting

- Excellent discharge quality

- No chemical addition for N & P removal

- Short construction period

- Small foot print

- Low cost/low energy

- Reduce carbon emissions

- Automated and unattended

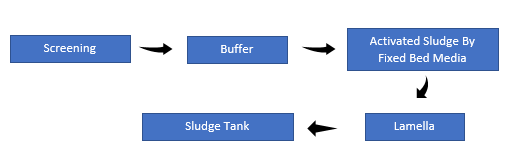

Flow chart is-

6- What is the principle of anaerobic digestion and its stages of digestion?

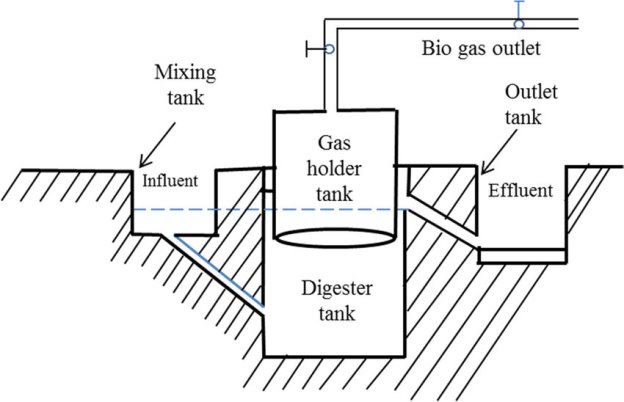

Principle of anaerobic digestion-

In anaerobic digestion process the organic material, in mixture of primary settled sludge and biological sludge from secondary clarifier, is converted to CH4 and CO2 under anaerobic conditions. This is carried out in an air tight reactor in absence of oxygen. Sludge is introduced continuously or intermittently and retained in the reactor for varying periods of time. Two basic processes involved in anaerobic digestion are liquifaction and gasification. The stabilized sludge which is withdrawn continuously or intermittently from the process, is non putrescible, and its pathogen content is also greatly reduced.

Anaerobic digestion is defined as being biological oxidation of degradable organic sludge by microbes under anaerobic condition. It occurs in absence of oxygen and organic matter acts as food source for microorganisms. Most microbes used in this digestion are obligate anaerobes or facultative type. This process is employed for treatment of the organic sludge.

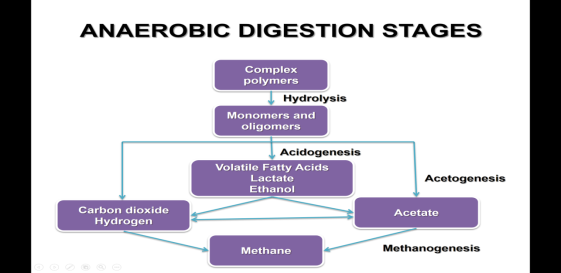

Stages of digestion-

The process of anaerobic digestion takes place through four successive stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis; the anaerobic digestion process is dependent on the interactions between the diverse microorganisms that are able to carry out the four aforementioned stages.

1- Hydrolysis-large organic compounds are converted into simple monomeric compounds. It is accomplished through extracellular enzymes.

2- Acidogenesis-the soluble monomeric compounds formed by hydrolysis undergo fermentation. The product obtained through acidogenesis are propionic acid and butyric acid .

3- Acetogenesis-With the production of acetate through acidogenesis, some of acetate is produced through mixed acid fermentation . Rest of acetate is produced through secondry fermentation of products obtained in previous stage. Acetate fermentation is important for formation of methane.

4- Methanogenesis- this is the last metabolic stage in anaerobic digestion . Methane is formed either from acetate ,carbon dioxide and hydrogen . The bacteria responsible for methanogenesis are called methagons .

7- How you can produced bio gas & its characteristics and application in india?

Biogas can be produced from a vast variety of raw materials (feedstocks). The biggest role in the biogas production process is played by microbes feeding on the biomass.

Digestion carried out by these microorganisms creates methane, which can be used as it is locally or upgraded to biogas equivalent to natural gas quality, enabling the transport of the biogas over longer distances. Material containing organic nutrients is also produced in the process, and this can be utilized for purposes such as agriculture.

Stages in biogas production

Biogas is produced using well-established technology in a process involving several stages:

- Biowaste is crushed into smaller pieces and slurrified to prepare it for the anaerobic digestion process. Slurrifying means adding liquid to the biowaste to make it easier to process.

- Microbes need warm conditions, so the biowaste is heated to around 37 °C.

- The actual biogas production takes place through anaerobic digestion in large tanks for about three weeks.

- In the final stage, the gas is purified (upgraded) by removing impurities and carbon dioxide.

Applications-

- Electricity generation

- In combined heat and power (CHP) plants

- Waste Management in agriculture

- Cooking fuel as a sustainable energy source

- Injection into a natural gas pipeline

- As a Clean Renewable Fuel for Transport Vehicles

- In Biogas Fuel Cells..

1. Electricity Generation

The application of biogas to electricity generation is the most common of all uses. Biogas made from plant material offers a renewable way to generate electricity. Unlike solar power available only during the day or wind power made only intermittently, biogas uses a reliable field crop grown and harvested by farmers.

Biogas possesses chemical energy, and therefore electricity from biogas comes as a result of converting this chemical energy to mechanical energy and finally into electricity. This is done by the use of transducers such as generators and turbines that convert energy from one form to another. This electricity can be used both domestically and commercially since it can be made in small and large scale.

2. In Combined Heat and Power (CHP) Plants

The application of biogas to produce combined heat and power should be as common as electricity generation, but the additional CHP plant requires additional investment, so the add-on equipment needed to use the waste heat may not be installed. Whenever that happens it should be seen as a missed opportunity. There is almost always a use to which the heat can be put, from electricity generation. Energy which would otherwise have to be wasted to the air around the cooling fans.

3. Waste Management in Agriculture

After energy we rate the next most important application of biogas is for agricultural (livestock) waste management. Crop residues and manure can be digested either alone or in co-digestion with other materials, employing either wet or dry processes. In the agricultural sector one possible solution to processing crop biomass is co-digested together with animal manures, the largest agricultural waste stream.

4. Biogas Applied to Use as a Cooking Fuel – A Sustainable Energy source

The application of biogas for cooking and baking is a promising option for improving the energy supply of the poor, i.e. over 2.7 billion people who rely on the inefficient and unhealthy burning of biomass as main energy source.

Provided the biogas is properly combusted, biogas stoves produce the lowest level of greenhouse gas emissions compared to other technologies that use fuel combustion, e.g. Biomass or fossil fuels. In this context, biogas stoves may help to reduce the impact on climate change of cooking practices in rural areas.

5. Injection Into a Natural Gas Pipeline

To understand the application of biogas as a fuel added into fossil fuel natural gas supply pipelines, needs to be explained.

When purified to a suitable extent to be injected in a natural gas pipeline, the pure gas is usually called “biomethane“. Biomethane injected in this way is in demand in many countries where the population is keen to comply with climate change reduction methods. The gas industry calls the compressed biomethane “Renewable Natural Gas” or RNG.

6- Fuel Cells

Theoretically, biogas can be converted directly into electricity by using a fuel cell. However, this process requires very clean gas and expensive fuel cells. Therefore, this option is still a matter for research and is not currently a practical option. The conversion of biogas to electric power by a generator set is much more practical.

Characteristics-

Non-polluting:

Biogas burns without smoke; hence no harmful gas such as CO2, CO, NO2, and SO2 are evolved.

Reduces Landfills:

The slurry produced after the production of biogas is used as manure in fields. The method of disposal is safe and efficient and hence no space is wasted in the form of landfills.

Cheaper technology:

Biogas plants require very little installation cost and become self-sufficient in a span of 3-4 months.

Generates employment:

Work opportunity for thousands of people is created, especially in rural areas.

Renewable source of energy:

It is considered as a renewable source of energy. Because the production is dependent on the generation of waste which is an endless process.

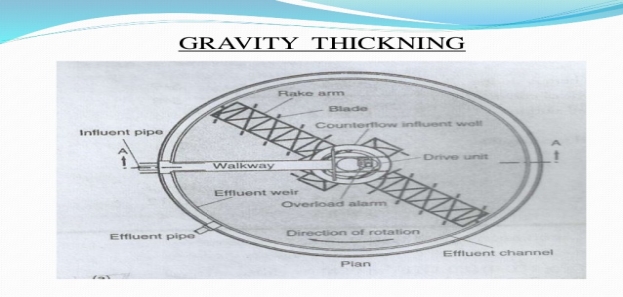

8- Explain dewatering of sludge by gravity thickener?

Sludge thickening or dewatering is adopted for reducing the volume of sludge and increasing the solid contents.

The main purpose of thickening is to increase the solid content of sludge by removing a portion of the liquid fraction.thickening is generally accomplished by physical means including gravity settling floatation etc.

Dewatering by gravity thickener is similar to conventional sedimentation. Normally a circular tank is used .it is more effective in primary sludge . Gravity thickener are designed on the basis of loading and over flow rate .

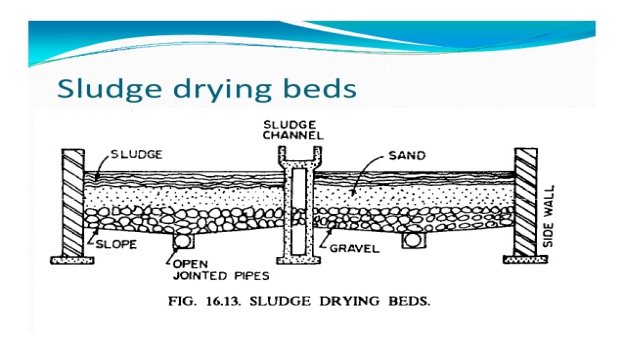

9- Define sludge drying beds & decanters?

Sludge drying bed (SDB) is the most widely used method for sludge dewatering. Sludge drying involves natural ways of drying to mechanical ways of removing water content. SDB is generally used for small and medium sized communities. The selection of the technology will depend upon land availability, climatic factors, the quantity and composition of the sludge. The construction of this is usually undertaken with civil structure.

Sludge-drying beds provide the simplest method of dewatering. A digested sludge slurry is spread on an open bed of sand and allowed to remain until dry. Drying takes place by a combination of evaporation and gravity drainage through the sand.

Decanters-

A decanter centrifuge (also known as solid bowl centrifuge) separates continuously solid materials from liquids in the slurry, and therefore plays an important role in the wastewater treatment, chemical, oil, and food processing industries.

The operating principle of a decanter centrifuge is based on separation via buoyancy. Naturally, a component with a higher density would fall to the bottom of a mixture, while the less dense component would be suspended above it. A decanter centrifuge increases the rate of settling through the use of continuous rotation.

The feed product is pumped into the decanter centrifuge through the inlet. Feed goes into a horizontal bowl, which rotates. The bowl is composed of a cylindrical part and a conical part. The separation takes place in the cylindrical part of the bowl. The fast rotation generates centrifugal forces up to 4000 x g. Under these forces, the solid particles with higher density are collected and compacted on the wall of the bowl. A scroll (also screw or screw conveyor) rotates inside the bowl at a slightly different speed. This speed difference is called the differential speed. This way the scroll is transporting the settled particles along the cylindrical part of the bowl and up to the end conical part of the bowl. At the smallest end of the conical part of the bowl, the dewatered solids leave the bowl via discharge opening. The clarified liquid leaves through a paring disc (internal centripetal pump)

10- Write down the various methods of sludge treatment & advantages and disadvantages of sludge disposal methods?

The residue that accumulates in sewage treatment plants is called sludge (or biosolids). Sewage sludge is the solid, semisolid, or slurry residual material that is produced as a by-product of wastewater treatment processes. This residue is commonly classified as primary and secondary sludge. Primary sludge is generated from chemical precipitation, sedimentation, and other primary processes, whereas secondary sludge is the activated waste biomass resulting from biological treatments. Some sewage plants also receive septage or septic tank solids from household on-site wastewater treatment systems. Quite often the sludges are combined together for further treatment and disposal.

Treatment methods

Treatment of sewage sludge may include a combination of thickening, digestion, and dewatering processes.

Thickening

Thickening is usually the first step in sludge treatment because it is impractical to handle thin sludge, a slurry of solids suspended in water. Thickening is usually accomplished in a tank called a gravity thickener. A thickener can reduce the total volume of sludge to less than half the original volume. An alternative to gravity thickening is dissolved-air flotation. In this method, air bubbles carry the solids to the surface, where a layer of thickened sludge forms.

Digestion

Sludge digestion is a biological process in which organic solids are decomposed into stable substances. Digestion reduces the total mass of solids, destroys pathogens, and makes it easier to dewater or dry the sludge. Digested sludge is inoffensive, having the appearance and characteristics of a rich potting soil.

Most large sewage treatment plants use a two-stage digestion system in which organics are metabolized by bacteria anaerobically (in the absence of oxygen). In the first stage, the sludge, thickened to a dry solids (DS) content of about 5 percent, is heated and mixed in a closed tank for several days. Acid-forming bacteria hydrolyze large molecules such as proteins and lipids, breaking them into smaller water-soluble molecules, and then ferment those smaller molecules into various fatty acids. The sludge then flows into a second tank, where the dissolved matter is converted by other bacteria into biogas, a mixture of carbon dioxide and methane. Methane is combustible and is used as a fuel to heat the first digestion tank as well as to generate electricity for the plant.

Dewatering-

Digested sewage sludge is usually dewatered before disposal. Dewatered sludge still contains a significant amount of water—often as much as 70 percent—but, even with that moisture content, sludge no longer behaves as a liquid and can be handled as a solid material. Sludge-drying beds provide the simplest method of dewatering. A digested sludge slurry is spread on an open bed of sand and allowed to remain until dry. Drying takes place by a combination of evaporation and gravity drainage through the sand. A piping network built under the sand collects the water, which is pumped back to the head of the plant. After about six weeks of drying, the sludge cake, as it is called, may have a solids content of about 40 percent. It can then be removed from the sand with a pitchfork or a front-end loader. In order to reduce drying time in wet or cold weather, a glass enclosure may be built over the sand beds. Since a good deal of land area is needed for drying beds, this method of dewatering is commonly used in rural or suburban towns rather than in densely populated cities.

Disposal

The final destination of treated sewage sludge usually is the land. Dewatered sludge can be buried underground in a sanitary landfill. It also may be spread on agricultural land in order to make use of its value as a soil conditioner and fertilizer. Since sludge may contain toxic industrial chemicals, it is not spread on land where crops are grown for human consumption.

Where a suitable site for land disposal is not available, as in urban areas, sludge may be incinerated. Incineration completely evaporates the moisture and converts the organic solids into inert ash. The ash must be disposed of, but the reduced volume makes disposal more economical. Air pollution control is a very important consideration when sewage sludge is incinerated. Appropriate air-cleaning devices such as scrubbers and filters must be used.

Dumping sludge in the ocean, once an economical disposal method for many coastal communities, is no longer considered a viable option. It is now prohibited in the United States and many other coastal countries.

Advantages and disadvantages of sludge disposal methods-

Treatment method | Advantages | Disadvantages |

Sanitary landfill | Low investment, need not to install other equipment. | Low stability of sludge will make it rotted to generate odor, and the moisture of sludge will permeate, which will pollute the underground water. In addition, the cost of landfills will also increase year by year. |

Incineration | Small occupation area, fast processing, large handing capacities; what’s more, the residual material can be sent to landfill or used as the constructional materials or paving accorduing to the content of heavy metal. | Large investment, and we need to install the specialized incineration with high maintenance cost; it will generate Dioxin and other highly toxic substances. |

Directly made into bricks | Realize the resource-based of sludge, which has an excellent social benefits. In the operation process, the heavy and harmful metal will be sealed in the bricks so as to can kill the harmful germs. Sludge brick is light with many hole, so it has a well sound insulation and thermal insulation effect. | The sludge source is unstable, and the high water content causes the large consumption with low burning quality. When firing, the whole process is accompanied by malodorous gases and toxic and harmful gases. |

Used as a fertilizer | Making the sludge resource utilized. | It needs a high temperature treatment to be made into fertilizer. It also needs to add a follow-up processing equipment such as turning machine. It also needs a large field. In addition, the sludge fertilizer must meet the related standards. |

Carbonization of sludge | High energy utilization, high capacity reduction, low operating costs; no dioxin, furan and other harmful gases; renewable energy recovery. | Require a certain amount of capital investment and technical support. |

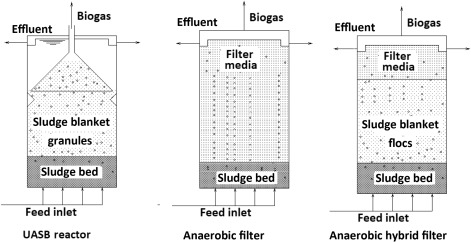

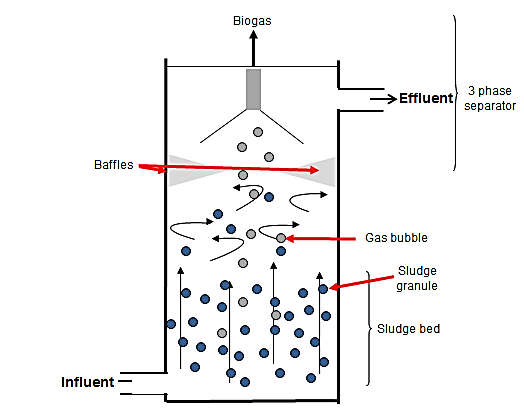

11- What is the principle of UASBR & its advantages and disadvantages?

Principle-

It maintains a high concentration of biomass through the formation of highly settleable sludge aggregates . The waste water flow upwards through a layer of very active sludge to cause anaerobic digestion .It is somewhat modified version of the contact process,. No inert medium is provided in these systems. The biomass growth takes place on the fine sludge particles, which then develop as sludge granules of high specific gravity.

The reactor can be divided in three parts (Figure 21.3), sludge bed, sludge blanket and three phase separator (gas-liquid-solid, GLS separator) provided at the top of the reactor. The sludge bed consists of high concentration of active anaerobic bacteria (40 – 100 g/L) and it occupies about 40 to 60% of reactor volume. Majority of organic matter degradation (> 95%) takes place in this zone. The sludge consists of biologically formed granules or thick flocculent sludge. Treatment occurs as the wastewater comes in contact with the granules and/or thick flocculent sludge. The gases produced causes internal mixing in the reactor. Some of the gas produced within the sludge bed gets attached to the biological granules. The free gas and the particles with the attached gas rise to the top of the reactor. On the top of sludge bed and below GLS separator, thin concentration of sludge is maintained, which is called as sludge blanket. This zone occupies 15 to 25% of reactor volume. Maintaining sludge blanket zone is important to dilute and further treat the wastewater stream that has bypassed the sludge bed portion following the rising biogas. The GLS separator occupies about 20 to 30% of the reactor volume. The particles that raise to the liquid surface strike the bottom of the degassing baffles, which causes the attached gas bubbles to be released. The degassed granules typically drop back to the surface of the sludge bed. The free gas and gas released from the granules is captured in the gas collection domes located at the top of the reactor. Liquid containing some residual solids and biological granules passes into a settling chamber, where the residual solids are separated from the liquid. The separated solids fall back through the baffle system to the top of the sludge blanket.

The wastewater enters the tank from the bottom and flows upwards through the sludge bed ,which can formed during the process itself. The sludge bed develops micro organisms capable of flourishing in the deficient environment .the sludge bed traps the suspended solids of upmoving waste water.

The methane or bio gas collected at the top of the collector from where it can be withdrawn to use as a by product.

Advantages and disadvantages of UASB reactor-

Advantages-

- High reduction in organics.

- Can withstand high organic loading rates (up to 10kg BOD/m3/d) and high hydraulic loading rates.

- the capital cost investment is about 20 lakh .

-electricity consumption in this system is quite low.

-the sludge production in this system is low.

- Biogas can be used for energy.

Disadvantages-

- Difficult to maintain proper hydraulic conditions (upflow and settling rate must be balanced).

- Long start up time.

- Treatment may be unstable with variable hydraulic and organic loads.

- Constant source of electricity is required.

- Not all parts and materials may be available locally.

- Requires expert design and construction supervision.

-the acid produced during the breakdown of organic matter in the UASB system may cause corrosion to the water.