Unit - 6

Level Measurement

Q1) Describe Linear Variable Differential Transformer?

A1) LVDT is an inductive type passive transducer. It measures force in terms of displacement of ferromagnetic core of a transformer. It converts translational or linear displacement into electrical voltage. It is also known as Linear Variable Differential Transducer. It is based on the principle of electromagnetic induction.

Q2) Explain the Operation of LVDT with advantages, disadvantages & applications?

A2) When the iron core lies at the centre of both secondary, the output differential voltage remains unaffected and have zero magnitude. When the core moves towards secondary-1, it induces more emf across it and less emf across secondary-2. Let’s assume that it is positive displacement. Due to more flux links with the secondary-1 than secondary-2. When the core moves towards secondary-2, it induces more emf across it and less emf across secondary-1. Lt’s assume that it is negative displacement. Due to more flux links with the secondary-2 than secondary-1. The output differential voltage is proportional to the displacement of the iron core.

Advantages

High Range (1.25mm-250mm)

No frictional losses

High input & high sensitivity

Low hysteresis

Low Power consumption

Direct conversion to electrical signals

Disadvantages

LVDT is sensitive to stray magnetic fields & always require a setup for protection

They are affected by vibrations & temperature

Applications

It is used where displacements ranging from fraction of mm to few cm are to be measured. It act as primary transducer.

They can also act as secondary transducer. E.g. The bourdon tube which acts as primary transducer and convert pressure into linear displacement then LVDT converts it into electrical signal.

Q3) Explain the principle & operation of Strain gauge?

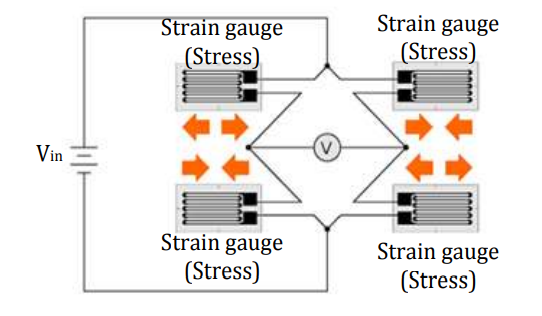

A3) Strain Gauge is used to measure strain on an object. As the object is deformed, the foil is deformed; this causes electrical resistance to change. The change in resistance usually a Wheatstone bridge, is related to the strain by the quantity known as gauge factor.

Principle

It is a sensor whose resistance varies with applied force. It converts force, pressure, tension, weight etc., into a change in electrical resistance which can then be measured.

Construction

It has resistive elements & can be connected in half bridge and full bridge type. It has various types as following; Bonded & Un-bonded metal wire type, wire type, foil type, frame type, sheath type

Operation

When the load or weight is acting on the strain gauge element, it deforms. The deformation in element causes the change in resistance of it. As per the balance and unbalance condition of the bridge, the voltmeter shows the output voltage. The output voltage is proportional to the change in resistance of the strain gauge elements and that change in resistance is proportional to the weight acting on it. Therefore, the output voltage varies with the weight. The fixed dc voltage source is required for this operation.

Advantages

High sensitivity to input

Low cost

Small size

Simple control

Fast response

Available in wide range

Disadvantages

They are affected by external vibrations & temperature

Errors

Q4) What are the different types of Strain gauge?

A4) Wire Strain Gauge

Metal Foil Strain Gauge

Semi Conductor Strain Gauge

Q5) What is Strain?

A5) Strain is the amount of deformation of a body due to an applied force. More specifically, strain (ε) is defined as the fractional change in length. Strain can be positive (tensile) or negative (compressive). Although dimensionless, strain is sometimes expressed in units such as in./in. Or mm/mm. In practice, the magnitude of measured strain is very small. Therefore, strain is often expressed as micro strain (µε), which is ε × 10–6. When a bar is strained with a uniaxial force, a phenomenon known as Poisson Strain causes the girth of the bar, D, to contract in the transverse, or perpendicular, direction. The magnitude of this transverse contraction is a material property indicated by its Poisson's Ratio. The Poisson's Ratio ν of a material is defined as the negative ratio of the strain in the transverse direction (perpendicular to the force) to the strain in the axial direction (parallel to the force), or ν = –εT/ε. Poisson's Ratio for steel, for example, ranges from 0.25 to 0.3.

Q6) Derive the Strain Gauge Equation?

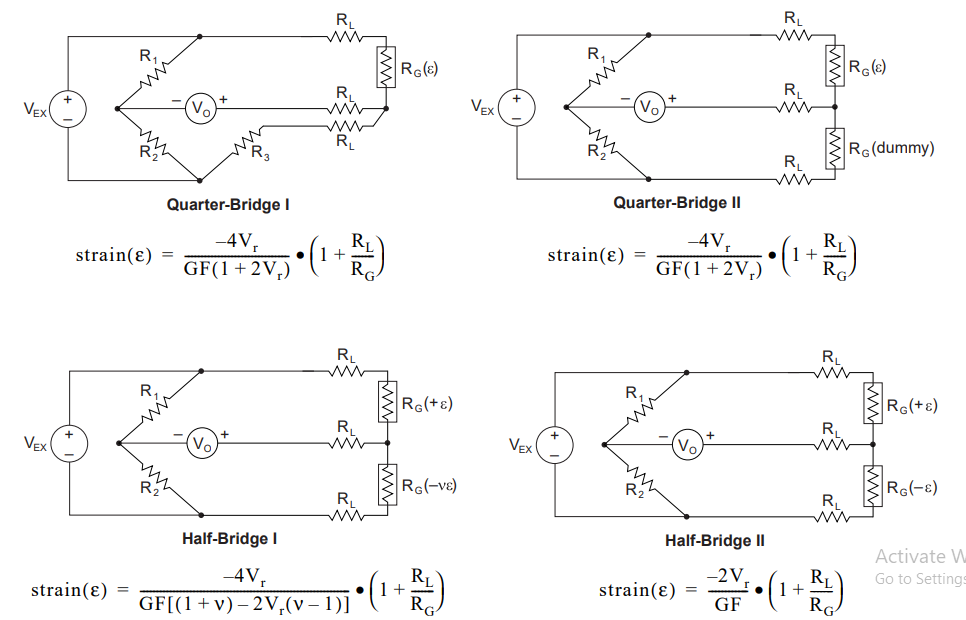

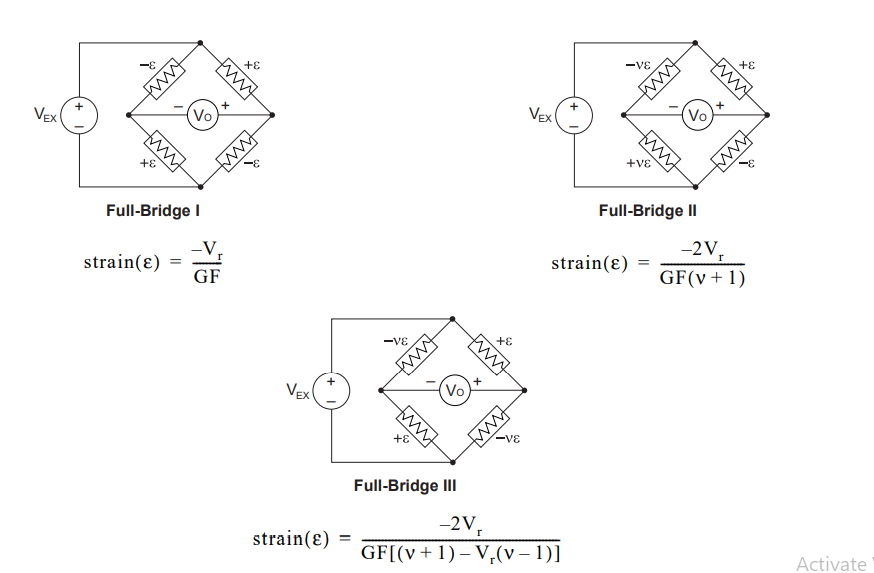

A6) This section includes the complete strain gauge equations for several types of bridge configurations. These equations are included as callable functions (with source code) with the NI-DAQ driver software. The function names are Strain_Convert and Strain_Buf_Convert. With LabVIEW, these equations are included in the Convert Strain Gauge Reading.vi in the DAQ Utilities menu.

To simplify the equations and account for unbalanced bridges in the nonstrained state, let us introduce the ratio Vr: where VO(strained) is the measured output when strained, and VO(unstrained) is the initial, unstrained output voltage. VEX is the excitation voltage. Also, the designation (+ε) and (–ε) indicates active strain gauges mounted in tension and compression, respectively. The designation (–νε) indicates that the strain gauge is mounted in the transversal direction, so that its resistance change is primarily due to the Poisson's Strain, whose magnitude is given as –νε. Other nomenclature used in the equations include: RG = nominal resistance value of strain gauge GF = gauge factor of strain gauge RL = lead resistance.

Vr= (VO(strained)-Vo(unstrained))/VEX

Q7) What are the applications of Strain gauge?

A7) Strain gauge technology has a huge amount of uses - almost unlimited. Strain gauges are a fundamental sensing element and are used within many different types of sensors. They are well used in industries such as; rail, aerospace, mechanical engineering and research and development. Some of the applications they have been used for include;

Stress on railway lines

Stresses on aircraft wing deflection

Aircraft component testing

Rotational strain on turbines, wheels, fans, propellers and motors

Testing ships hulls

Testing structural components for bridges and buildings

Automotive testing

Q8) Define Electronic Level Measurement?

A8) Electronic level measurement

Contactless level measurements in the tank are carried out by ultrasonic measurement. Ultrasonic waves are transmitted to the underlying surface of the liquid and the echo time used to calculate the tank contents is measured. The tank content is reported in liters / centimeter / percent.

Q9) Define Ultrasonic level measurement and its advantages?

A9) Ultrasonic measurement: Measuring Principle

A sensor emits ultrasonic pulses, the surface of the media reflects the signal and the sensor detects it again. The Time-of-Flight of the reflected ultrasonic signal is directly proportional to the distance traveled. With the known tank geometry the level can be calculated.

Benefits

Non-contact, maintenance-free measurement

Measurement unaffected by media properties, like dc value or density

Calibration without filling or discharging

Self-cleaning effect due to vibrating sensor diaphragm

Q10) Explain the principle of Nucleonic level measurement?

A10) The nucleonic measuring principle is based on the attenuation of gamma radiation as it penetrates materials. The radioactive isotope (gamma source) is installed in a container, also referred to as shielding, which emits the radiation only in one direction.

The source container and the transmitter detecting the radiation are usually mounted on opposite sides of a vessel or pipe.

The emitted radiation (e.g. Gamma rays) passes through the vessel walls and the medium contained in the vessel. The actual measuring effect results from the absorption of the radiation by the medium.

The intelligent transmitter calculates the level, density or the concentration of the medium from the radiation received. The higher the level or the density of the medium in the vessel the lower the intensity of the radiation received.

In conventional level and density measurements 137 Cesium and 60 Cobalt are commonly used. 241 Americium or 244 Curium may be used for heavy element measurement in a medium consisting of lighter elements.