Unit 03

Insulating materials, properties & applications

Q1) Explain insulating gases. Like SF6 and air.

A1) Insulating gases like air and SF6 provide excellent insulation as an insulating gas. It is more suitable for different climate situations due to its lower boiling point (-64 degree C).

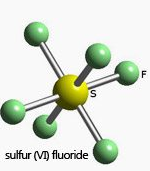

SF6- sulphur hexafluoride gas (SF6) is engaged as insulation in all parts of installation, or in the circuit breaker for arc quenching. This gas is electronegative gas, its atmospheric pressure for dielectric strength 3 times that of the air.

It is non-toxic, incombustible and chemically inert with the arc-quenching properties 3 to 4 times which better than air at similar pressure. SF6 commercially available is not dangerous and this is not hazardous materials order or technical regulations on hazardous substances (TRGS).

Q2) What materials are used in power and distribution transformer?

A2) Insulating oil

Insulating oil plays a too important role in transformer insulation system. In the low voltage transformer, transformers are utilized in the range of the 12 to 1000V or low power ratings transformers so there is no requirement of the insulating oil in these transformers. In low voltage transformers heat dissipation is very low. Transformer oil is used as a coolant. And it takes place in a tank in that core of transformer is placed.

Insulating paper

Paper is fabric which is made from vegetables fibers that are felted to the form a sheet or web. The raw materials of the fibrous are acquired from the plants involving hemp, cotton, straw, manila and coniferous trees. It reaches a high value of the electric strength while combined in the oil under vacuum. “craft insulating paper of the medium air permeability” is utilized in the layer winding insulation, oil impregnated busing condenser core. This paper is utilized for covering over the rectangular copper conductor and regularly transposed copper conductor. “crepe kraft paper” is utilized for covering across flexible copper cable insulation of the winding lead.

Pressboard

Pressboard is broadly utilized insulating substances for building a variety of elements utilized in the mechanical, electrical and thermal design of the transformers. ID of the pressboard made from the vegetable’s fibers, cells of these keeps more cellulose. The more typical practical insulation in the power transformer happen at the last of windings and lead outs from windings. Pressboard shaped elements can be developed to any type of shape required. Angle caps and rings are broadly utilized shaping. There are many types of pressboard utilize in the high voltage transformers but “ soft pressboard-laminated” is utilized in the 11KV transformers as a block washer, support and terminal gear cleat and spacer etc.

Wood

Laminates which are made from the wood are manufactured form the chosen veneers acquired from different timbers. The veneers are fully impregnated and dried with the natural phenomenon. The areas that are required high mechanical and low electric strength, laminated wood densities is utilized for developing a insulation variety elements such as cleat, coil clamping ring, core, support and yoke etc.

Q3) What are the factors important in choosing a lagging materials?

A3) The unique choice of the thermal insulating materials are an engineering decision including a many factors, these are following:

Temperature of the system, when the system is operating.

Thermal conductivity of the insulation materials.

Resistance to chemicals and fire.

Jacketing insulation.

Total cost in which including maintenance costs.

When using not find any cracking or shrinkage.

In applications ability of the insulation to the hot surfaces cheaply and readily.

Resistance to the heat, adverse atmospheric conditions and weather.

Ability to the withstand noise, vibration and accidental mechanical damages.

Q4) Describe “emissivity” and “economic thickness of the insulation”? explained in details.

A4) Emissivity

It is the measurement of the ability of the materials to both radiate heat and absorb. When materials have the higher emissivity qualities have the heat transfer benefits efficiency and the materials service life. Coatings for high emissivity are applied on the interior surface of furnace.

Economic thickness of the insulation

This is limiting value is known s economic thickness of the insulation. Each industry has the various fuel cost and efficiency of the boiler. These values can be utilized for the calculating the economic thickness of the insulation. This provide the thickness of the given set of the circumstance’s outcomes in lowest complete cost of the insulation and loss of the heat combined across the given time period. The following shown below the principle of the economic thickness of the insulation.

Cost of the insulation-

Total cost: I+H

H: heat loss cost

M: Economic thickness

The economic thickness needs attention to following factors.

Annual hours of the operation

Thickness/diameter of pipe surface

Estimated insulation cost

Average exposure of the ambient still the sir temperature.

Q5) Define qualities of the good insulating materials?

A5) Insulating materials have the main characteristics are its heat and insulation resistance. We can measure insulation by insulation strength, ability of the heat resistance of the insulating materials under the high temperature without any changes of dielectric, chemical and mechanical properties. A good insulating material have the following characteristics are-

1.Highest insulating resistance

2.Higher dielectric strength

3.Uniform viscosity- it provides uniform thermal and electrical properties.

4.Must be uniform throughput- it contains electric loss as low as potential and electric stress uniform 5.under the high voltage differences.

6.Minimum thermal expansion

7.While revealed to arcing must be non-ignitable.

8.Must be resistance to oils or liquids, acids, gas fumes and alkalies.

9.Must have no deteriorating impact on material when in contact with it.

10.Loss tangent (low dissipation factor)

11.Higher mechanical strength

12.Higher thermal conductivity.

13.Lower permittivity.

14.Higher thermal strength

15.To avoid discharges for free from the gaseous (for gases and solids)

16.Must be homogeneous to avoid the local stress concentration.

17.Must be resistant with the chemical and thermal deterioration.

Q6) Describe the applications of the insulating materials?

A6) Circuit breakers applications are

Epoxy resins are used in low pressure casting for bushing, instrument transformer, bus bars, switchgear orifices.

Silicone rubber is used for moulded joint is filled with the SF6 in insulated circuit breakers.

High voltage bushing applications are

When the voltage is higher than 52 kv, capacitance and condenser graded bushing principle is normally utilized. Insulating materials are for these applications in the high voltage bushings are paper that is treated. We introduce three types of papers such as

Oil impregnated paper (OIP), resin impregnated paper (RIP) and resin bonded paper (RBP).

Applications for fractional horse power motors.

These are used in automobile industry and mass produced materials. So the insulation system should guarantee of reliability, merged with the good procedural capability, tolerance and mechanical strength to severe short thermal stress during operations.

These small size motors are made widely and utilized in the automobile industry and household appliances. They must provide good services in the operations that include vibrations. This kind motors manufactures are utilizing the pressboard as the main insulation materials.

Q7) Give explanation for the insulation materials for capacitor?

A7) Different types of capacitors are utilized significantly for the DC applications. For apper capacitors, paper with impregnates such as castor oil, minerals oil, synthetic oils and polyesters etc. electrolytic capacitors are with the aluminum or tantalum, ceramic capacitors with the variety of the ceramic bodies like tubular, blocking and disc etc. and film dielectric capacitors like Teflon, polystyrene and polyethylene etc.

Q8) Describes insulating materials are line insulators and switchgears?

A8) Line insulators

In insulators lines porcelain has been utilize a most acceptable insulation medium for the transmission lines. In high voltage systems weight has been proved to the major constraints. In insulators lines glass insulators are used.

Switchgear

The MCB (miniature circuit breakers that operate on very high currents and high voltage utilize both the gases and liquids arc interrupting coolant medium. In the oil filled breakers, petrol is utilized in transformer is utilized.

Q9) Compare the active and passive dielectric materials?

A9)

Active dielectrics | Passive dielectrics |

Materials which can easily adapt the electrical energy called active dielectrics | Materials which are restrict the flow of electrical energy called passive dielectrics. |

These are utilized in the production of the ultrasonic. | These are utilized in production sheets and pipes. |

Piezo electric and ferro electrics | Glass, mica and pipes etc. |

Q10) What is thermal and intrinsic breakdown?

A10) Intrinsic breakdown

In dielectric materials, charge displacement is increased with the improving electrical field strength. When it get beyond the critical vale of the electrical field strength, there is an electrical breakdown is occurred due to the physical deterioration in dielectric materials.

Thermal breakdown

Electrical field is applied to the dielectric materials, heat some amount is produced. This heat should be dissipated from materials. When heat amount is too large as compared to heat is dissipated. Due to the heat excess dielectric temperature which is inside is increases and may produce local melting in the materials. Large amount of current is flows by the materials during this process and these are causes of the dielectric breakdown. This breakdown is called thermal breakdown.