Unit 4

Q.1 What is absolute and incremental coordinate system?

A1) In the absolute programming, the end point of a motion is programmed with reference to the program zero point.

In incremental programming, the end point is specified with reference to the current tool position.

Absolute traverse to N1, then to N2

X20.0 Z50.0 X50.0 Z30.0

Absolute traverse to N1, incremental to N2

X20.0 Z50.0 U30.0 W-20.0

Q.2 Explain Zero points or reference points.

A2)

Origin is always located at some position on M/C table (usually at south west corner/Lower left-hand) of the tables & all tool location are defined W.R.T. this zero

2. Workpiece Zero or Fixed Zero (A)

Very common with CNC M/C used now a days. Operator gas lobeity to set zero point at any convenient position on M/C table. Blocking point is the workpiece zero point

3. Program Zero Point (W)

Program zero point is the starting point of workpiece blank

4. Start point (B)

Start point is to be determined in the program

5. Reference point (R)

The reference is to be determined by measuring system. The distsnce between R and M must be known. Normally R is not fixed.

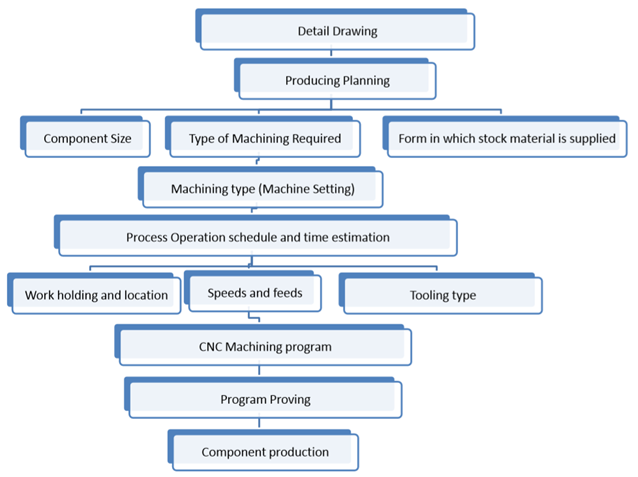

Q.3 What are the steps involved in part programming?

A3)

Q.4 Give the function of following G and M codes.

A4)

G00 Positioning rapid traverse

G01 Linear interpolation (feed)

G02 Circular interpolation CW

G03 Circular interpolation CCW

G04 Dwell

G41 Tool nose radius compensation left

G42 Tool nose radius compensation right

G90 Absolute command

G91 Incremental command

G94 Feed per minute

G95 Feed per revolution

G98 Return to initial point in canned cycle

G99 Return to R point in canned cycle

M01 Optional program stop request

M02 Program end

M03 Spindle ON clock wise (CW)

M06 Tool change

M07 Mist coolant ON (coolant 1 ON)

M09 Coolant OFF

M30 End of program, Reset to start

Q.5 What is tool length compensation?

A5) Different tools of different lengths are used in machining any part. The lengths of the tools are not considered in the part program. They are entered in the machine’s memory, and are considered automatically for each motion in the program depending on the tool that is being used. The tool lengths in the Z direction are called the Tool length offsets.

Codes Function

G43 Make the value of the cutter’s offset add to the value of Z coordinates of the program

G44 Make the value of the cutter’s offset subtract the value of Z coordinates of the Program

G49 Cancel the offset of the length of the cutter

The procedure of mentioning the difference of length of tool assumed during programming and actual tool used for machining is called tool length compensation

1) If the actual tool length is more than the assumed tool, the difference should be mentioned as follows

G43 H01

H01 – here 01 specifies the address where the difference of tool will be mentioned

2) If the actual tool length is less than the assumed tool, the difference should be mentioned as follows

G44 H01

H01 – here 01 specifies the address where the difference of tool will be mentioned.

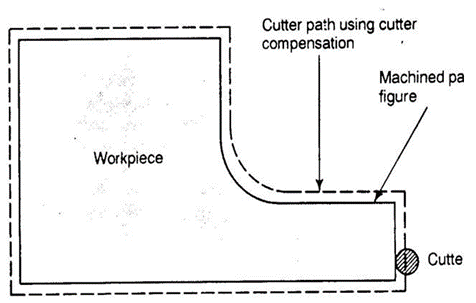

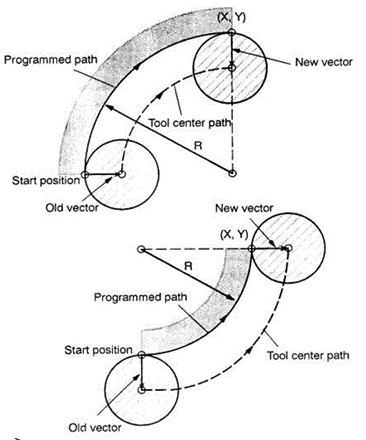

Q.6 Explain cutter radius compensation.

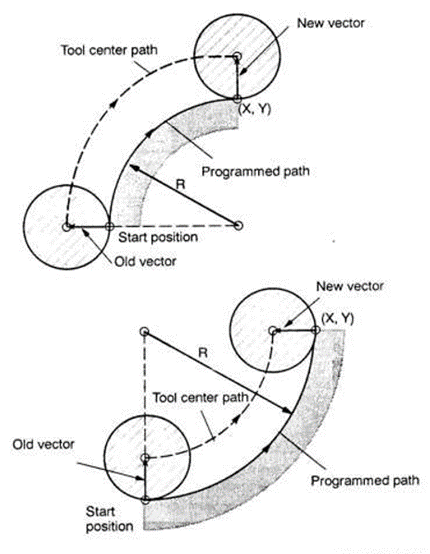

A6) When the Endmill cutter of some specified diameter is commanded to position at a location, actually the centre point of the cutter only coincide with the addressed point of the work piece.

So, it is necessary to shift the cutter for a radius amount towards left or right from the position. The procedure of shifting the tool of radius amount is called as Cutter Radius Compensation

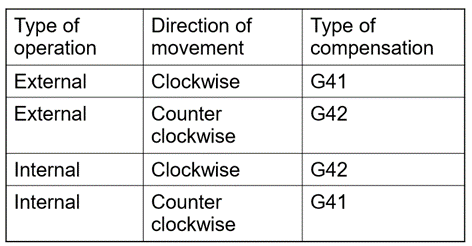

G41 - Cutter radius compensation left

G42 - Cutter radius compensation right

G40 - Cutter radius compensation cancel

The type of compensation is selected from the starting point as follows

G41 - Cutter radius compensation left

G41 D07;

Here, D specifies the address of offset at which the radius of tool will be mentioned

G42 - Cutter radius compensation right

G41 D07;

Here, D specifies the address of offset at which the radius of tool will be mentioned

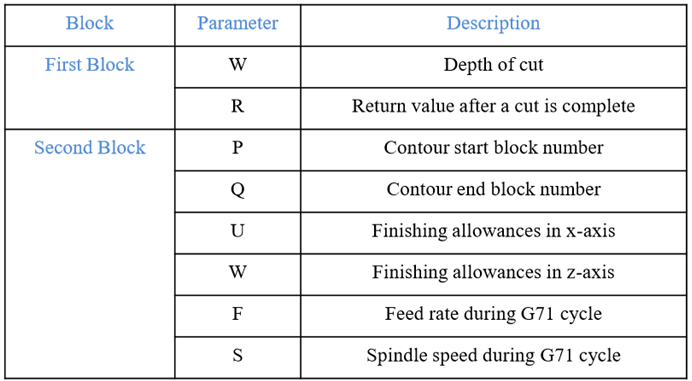

Q.7 Explain canned cycle for facing and grooving with example.

A7) Canned cycle for facing

G72 cycle is used for facing operation.

Programming syntax:

G72 W… R…

G72 P… Q… U… W… F… S…

G72 Facing Cycle Example:

N5 G00 X65 Z42

N6 G72 W2 R2

N7 G72 P8 Q9 U0 W0 F0.3

N8 G00 Z30

N9 G01 X20

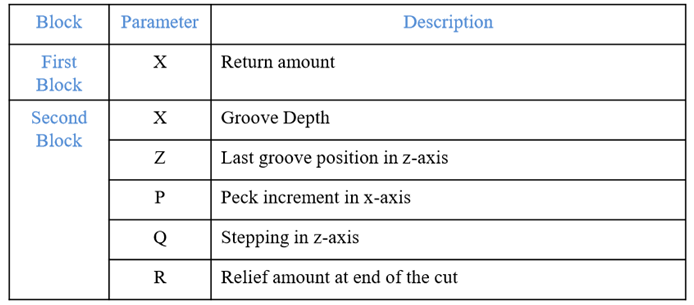

Canned Cycle for Grooving

G75 cycle is used for grooving

Programming syntax :

G75 X…

G75 X… Z… P… Q… R…

G75 Canned Cycle Grooving CNC Programming Example

N10 G50 S500 T0100

N20 G97 S400 M03

N30 G00 X90.0 Z1.0 T0101

N40 G00 X82.0 Z-60.0

N50 G75 R1.0

N60 G75 X60.0 Z-20.0 P3000 Q20000 F0.1

N70 G00 X90.0

N80 G00 X200.0 Z200.0 T0100

N90 M30

Q.8 Explain canned cycle for drilling operation.

A8) G81 canned cycle is used for drilling

Programming syntax :

G81 X... Y... Z... R... K... F...

Working Example:

N10 T1 M06

N20 G90 G54 G00 X30 Y25

N30 S1200 M03

N40 G43 H01 Z5 M08

N50 G81 Z-10 R2 F75

N60 X80 Y50

N70 G80 G00 Z100 M09

N80 M30

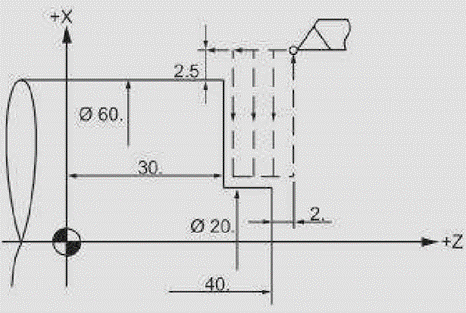

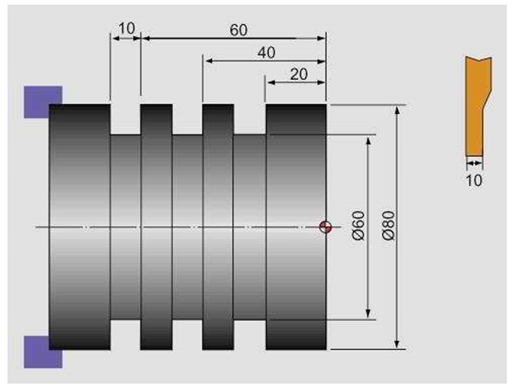

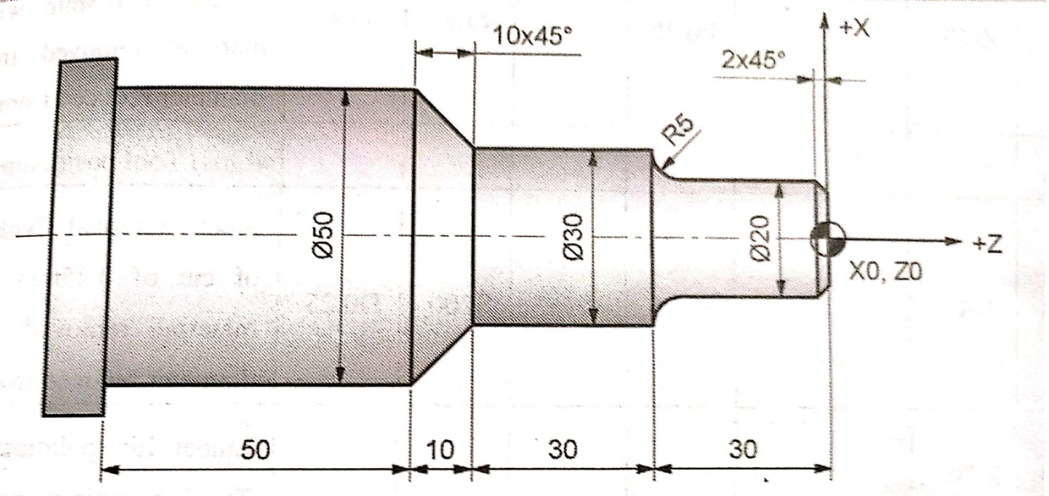

Q.9 Write NC Part Program for the part as shown in fig. Assume suitable data.

A9) Assumptions:

Spindle speed N = 200 rpm

Feed rate f = 0.25 mm/rev

Program:

O1006

N0 G90

N1 G71

N2 G92 M43 S200

N3 G95

N4 G28 U0 V0

N5 M06 T0101

N6 M03 S200

N7 G00 X60 Z1 M08

N8 G73 X52 Z-120 F0.25 S200 D0.5

N9 G00 X52 Z1

N10 G73 X50 Z-120 F0.25 S200 D0.25

N11 G00 X51 Z1

N12 G73 X32 Z-60 F0.25 S200 D0.5

N13 G00 X33 Z1

N14 G73 X30 Z-60 F0.25 S200 D0.25

N15 G01 X50 Z-70

N16 G01 X51 Z1

N17 G01 X31 Z1

N18 G73 X22 Z-25 F0.25 S200 D0.5

N19 G00 X23 Z1

N20 G73 X20 Z-25 F0.25 S200 D0.25

N21 G03 X30 Y-30 I00 K-5 F0.25

N22 G00 X31 Z1

N23 G00 X16 Z0

N24 G01 X20 Z-2

N25 G00 X21 Z1

N26 G00 X0 Z0

N27 G28 U0 W0

N28 M05

N29 M09

N30 M02

N31 M30

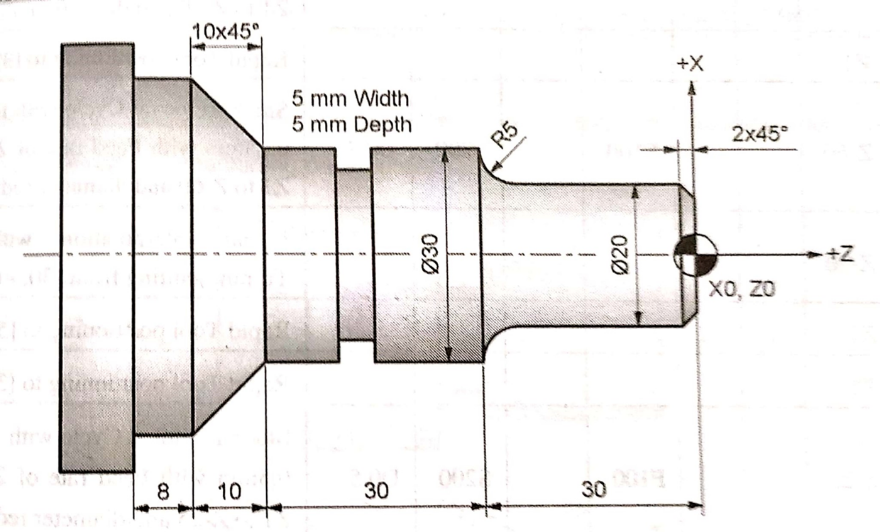

Q.10 Write a part program to machine the component as shown in fig.

A10) Assumptions:

Spindle speed N = 200 rpm

Feed rate f = 0.25 mm/rev

Program:

O1007

N0 G90

N1 G71

N2 G92 M43 S200

N3 G95

N4 G28 U0 V0

N5 M06 T0101

N6 M03 S200

N7 G00 X60 Z1 M08

N8 G74 X52 Z-78 F100 S200 D0.5

N9 G00 X53 Z1

N10 G74 X50 Z-78 F100 S200 D0.25

N11 G00 X51 Z1

N12 G74 X32 Z-60 F100 S200 D0.5

N13 G100 X51 Z1

N14 G74 X30 Z-60 F100 S200 D0.25

N15 G01 X50 Z-71

N16 G01 X51 Z1

N17 G01 X31 Z1

N18 G74 X22 Z-25 F100 S200 D0.5

N19 G00 X23 Z1

N20 G74 X20 Z-25 F100 S200 D0.25

N21 G03 X30 Y-30 I00 K-5 F100

N22 G00 X31 Z1

N23 G00 X16 Z0

N24 G01 X20 Z1

N25 G00 X21 Z1

N26 M06 T0201

N27 G00 X31 Z-45

N28 G01 X24 Z-45

N29 G00 X31 Z-45

N30 G00 X31 Z1

N31 G00 X0 Z1

N32 G28 U0 W0

N33 M05

N34 M09

N35 M02

N36 M30

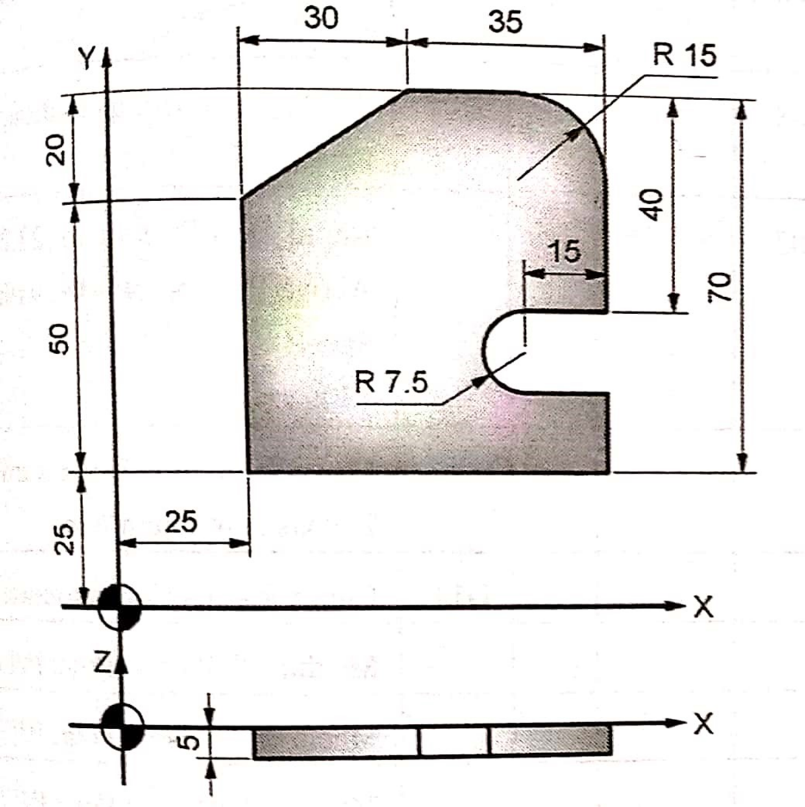

Q.11 Write a CNC program to cut a slot for the component shown inn fig, by using a end mill of dia 6mm. The depth of slot is 2mm. Assume suitable data.

A11) D = 6 mm

Assume:

V = 25 m/min

Fz = 0.1 mm/tooth

Take Z = 3

F = Fz Z N = 0.1 x 3 x 1300 = 390 mm/min or 400 mm/min

Program:

O1008

N0 G17

N01 G71

N02 G40

N03 G80

N04 G28 U0 V0 W0

N05 G91 X0

N06 G00 X0 Y0

N07 G92

N08 M06 T01

N09 G00

N10 G90 X0 Y0

N11 G43 Z0 M08 H01

N12 G00 X22 Y22 M03 S1300

N13 G01 Z-2 F400

N14 G42 X25 D11

N15 G01 X0

N16 Y40

N17 X75

N18 G02 X75 Y55 I00 J7.5

N19 G01 X90

N20 Y80

N21 G03 X75 Y95 I-15 J00

N22 G01 X55

N23 X25 Y75

N24 Y25

N25 G00 Z0

N26 G28 U0 V0 W0

N27 G91 Z0

N28 G28 U0 V0 W0

N29 G91 X0 Y0 M05

N30 G40

N31 G80

N32 G49

N33 M09

N34 M02

N35 M30

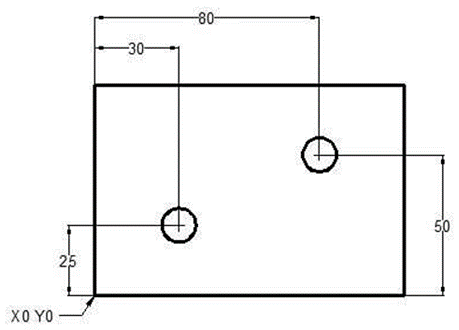

Q.12 Write a CNC program for drilling the three holes in part as shown in fig

A12) Drill Dia = D =10 mm

Assume:

V = 60 m/min

Fz = 0.5 mm/tooth

Thickness of plate = 10 mm

Take Z = 1

F = Fz Z N = 0.5 x 1 x 1900 = 954.93 mm/min or 900 mm/min

Program:

O1009

N0 G17

N01 G71

N02 G40

N03 G80

N04 G28 U0 V0 W0

N05 G91 X0

N06 G00 X0 Y0

N07 G92

N08 M06 T01

N09 G00

N10 G90 X0 Y0

N11 G43 Z2 M08 H01

N12 G00 X12 Y55 M03 S1900

N13 G01 Z-10 F950

N14 G00 Z2 M05

N15 G00 X30 Y35 M03 S1900

N16 G01 Z-10 F950

N17 G00 Z2 M05

N18 G00 X60 Y25 M03 S1900

N19 G01 Z-10 F950

N20 G00 Z2 M05

N21 G00 Z0

N22 G28 U0 V0 W0

N23 G91 Z0

N24 G28 U0 V0 W0

N25 G91 X0 Y0 M05

N26 G80

N27 G49

N28 M09

N29 M02

N30 M30