Unit 2

Q.1 Explain Types of single acting cylinder

A1) Single Acting Cylinder:

It consists of a piston inside a cylindrical housing called barrel. On one end of the piston there is a rod, which can reciprocate. At the opposite end, there is a port for the entrance and exit of oil.

Fig. Single Acting Cylinder

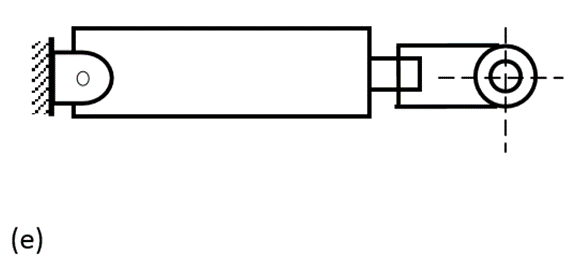

According to the type of return, single-acting cylinders are classified as follows:

Gravity return Single Acting Cylinder:

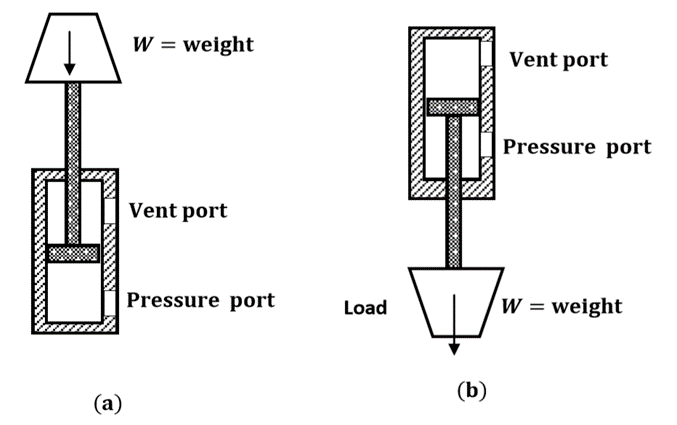

Figure shows gravity-return-type single-acting cylinders.

Fig. Gravity Return Single Acting Cylinder (a)push type (b)pull type

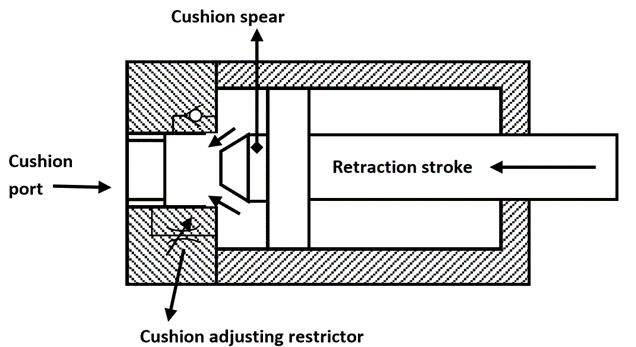

Spring Return Single Acting Cylinder:

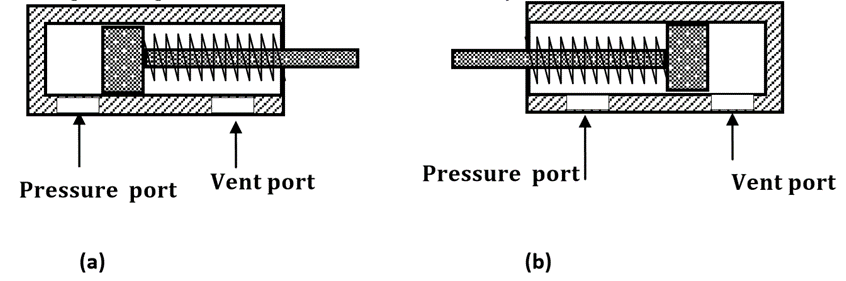

A spring-return single-acting cylinder is shown in Fig.

Fig. Spring Return Single Acting Cylinder (a)Push type (b)Pull type

Q.2 Write a note on Telescopic cylinder

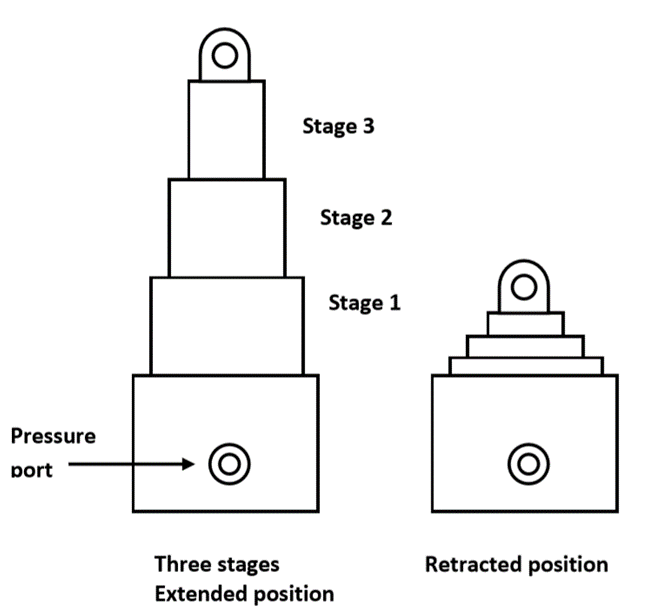

A2) A telescopic cylinder (shown in Fig.) is used when a long stroke length and a short retracted length are required.

Fig. Telescopic Cylinder

The telescopic cylinder extends in stages, each stage consisting of a sleeve that fits inside the previous stage. One application for this type of cylinder is raising a dump truck bed. Telescopic cylinders are available in both single-acting and double-acting models.

Q.3 Explain Tandem Cylinder

A3)

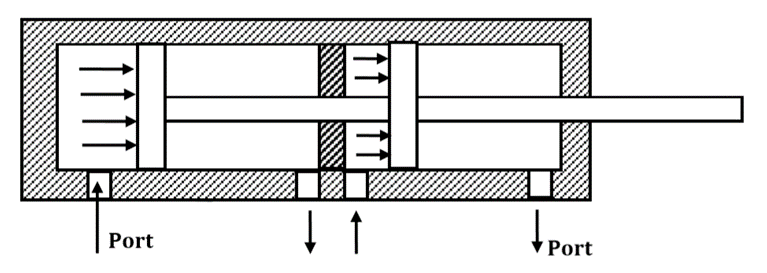

Fig. Tandem Cylinder

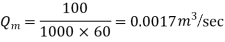

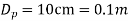

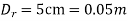

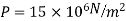

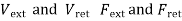

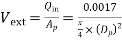

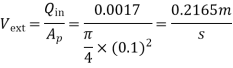

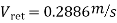

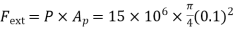

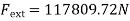

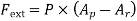

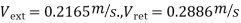

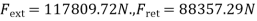

Q.4 A 10 cm hydraulic cylinder has 5 cm diameter rod. If the cylinder receives flow at 100 LPM and 15 MPa. Find

1. Extension and retraction speeds

2. Extension and retraction load carrying capacities

A4)

Given:

To find :

a)

b)

Ans:

a)

b)

Q.5 Write a note on Gear motor.

A5)

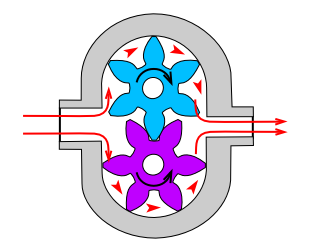

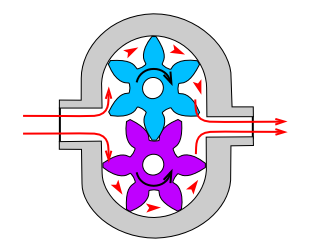

Fig. Hydraulic gear motor

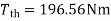

Q.6 Explain Vane motor in detail

A6)

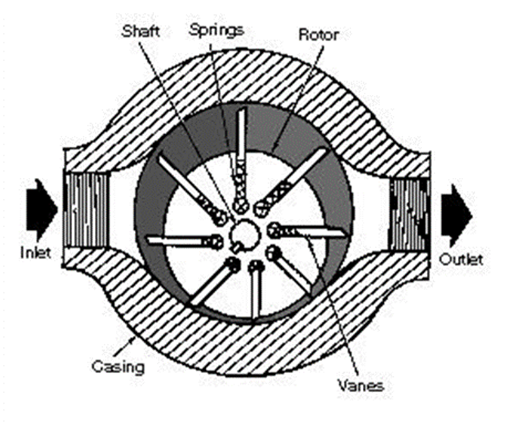

Fig.Unbalanced Hydraulic Vane Motor

Following figure shows the balanced vane motor.

Fig. Balanced Hydraulic Vane Motor

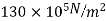

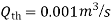

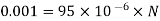

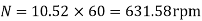

Q.7 A hydraulic motor has a 95 cm3, volumetric displacement. If it has a pressure rating of 130 bar and receives oil from a 0.001 m3/s theoretical flow rate pump, find the motor speed, theoretical torque and theoretical power in kW.

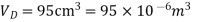

A7) Given: Use

1)

1)

P=130bar= 2)

2)

3) Power=

3) Power=

1) Speed : Theoretical flow rate can be given as,

2) Theoretical Torque:

3) Theoretical Power(kW):-

Power=P=13,000W =13kW

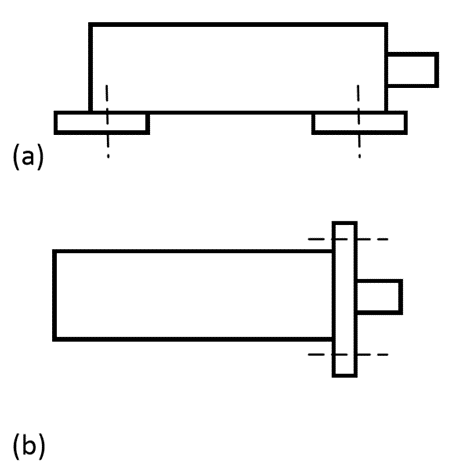

Q.8 Write a note on cylinder mountings

A8) The various kinds of mountings normally used in industries are as follows

It should be designed to give a limited amount of movement on one foot only to allow for thermal or load expansion. That is, the cylinder should be positively located or dowelled at one end only.

2. Rod-end flange or front flange mounting:

During the extend stroke, pressure in the hydraulic fluid acts on the cylinder-end cap, the force set up being transmitted to the front mounting flange through the cylinder body.

3. Rear flange, back flange or head-end flange mounting:

No stress is present in the cylinder owing to load on the extend stroke; only hoop stress is present. The load acts through the fluid onto the rear flange.

4. Trunnion mounting:

It allows angular movement. It is designed to take shear load only. Bearing should be as close to the cylinder body as possible.

5. Eye or clevis mounting:

There is a tendency for the cylinder to jack knife under load. Side loading of bearing must be carefully considered.

Fig. (a) Foot mounting; (b) rod-end flange or front flange mounting; (c) rear flange, back flange or head-end flange mounting; (d) trunnion mounting; (e) eye or clevis mounting.

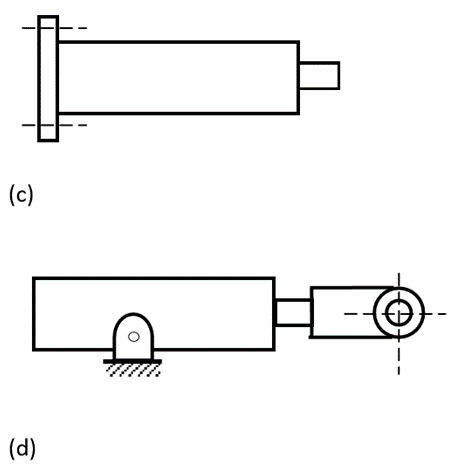

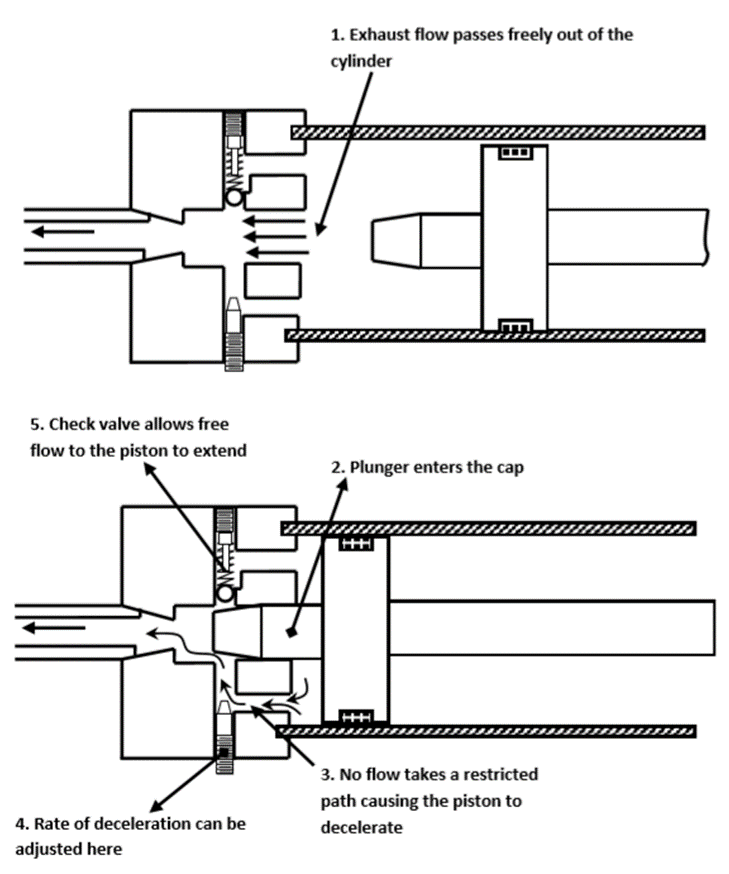

Q.9 Explain Cylinder cushioning

A9)

A typical cushioning arrangement is shown in Fig.

Fig. Hydraulic Cylinder with cushioning

Fig. Operations of Cylinder Cushions

Q.10 What are seals? Classify Seal.

A10) “Seals are used in hydraulic systems to prevent excessive internal and external leakage and to keep out contamination.”

Various functions of seals include the following:

Classification of hydraulic seals

1. According to the method of sealing:

2. According to the relative motion existing between the seals and other parts:

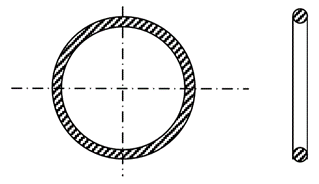

3. According to geometrical cross-section:

Fig. O-ring

Fig. V-ring and U-ring Seal

Fig. T-ring seal

Q.11 Explain Filters and strainers.

A11)

They are devices whose primary function is the retention, by some fine porous medium, of insoluble contaminants from fluid. Filters are used to pick up smaller contaminant particles because they are able to accumulate them better than a strainer. Generally, a filter consists of fabricated steel housing with an inlet and an outlet. The filter elements are held in position by springs or other retaining devices. Because the filter element is not capable of being cleaned, that is, when the filter becomes dirty, it is discarded and replaced by a new one. Particle sizes removed by filters are measured in microns. The smallest sized particle that can be removed is as small as 1 µm. A strainer is a device whose function is to remove large particles from a fluid using a wire screen. The smallest sized particle that can be removed by a strainer is as small as 0.15 mm or 150 µm.

2. Hydraulic strainers:

A strainer is a coarse filter. Fluid flows more or less straight through it. A strainer is constructed of a fine wire mesh screen or of screening consisting of a specially processed wire of varying thickness wrapped around metal frames. It does not provide as fine a screening action as filters do, but offers less resistance to flow and is used in pump suction lines where pressure drop must be kept to a minimum. A strainer should be as large as possible or wherever this is not practical, two or more may be used in parallel.