Unit 5

Q.1 Differentiate between hydraulic and pneumatic systems

A1)

Sr. No. | Hydraulic System | Pneumatic System |

1 | It employs a pressurized liquid as fluid | It employs a compressed gas usually air as a fluid |

2 | Oil hydraulics system operates at pressures upto 700 bar. | Pneumatics systems usually operate at 5 to 10 bar. |

3 | Generally designed for closed systems | Pneumatic systems are usually designed as open system |

4 | System get slow down of leakage occurs | Leakage does not affect the system much more |

5 | Valve operations are difficult | Easy to operate the valves |

6 | Heavier in weight | Light in weight |

7 | Pumps are used to provide pressurized liquids | Compressors are used to provide compressed gas |

8 | System is unsafe to fire hazards | System is free from fire hazards |

9 | Automatic lubrication is provided | Special arrangements for lubrication needed. |

Q.2 Write down advantages and disadvantages of pneumatic system

A2) Advantages of Pneumatic system

Disadvantages of Pneumatic systems

Q.3 Explain with neat sketch piston compressor

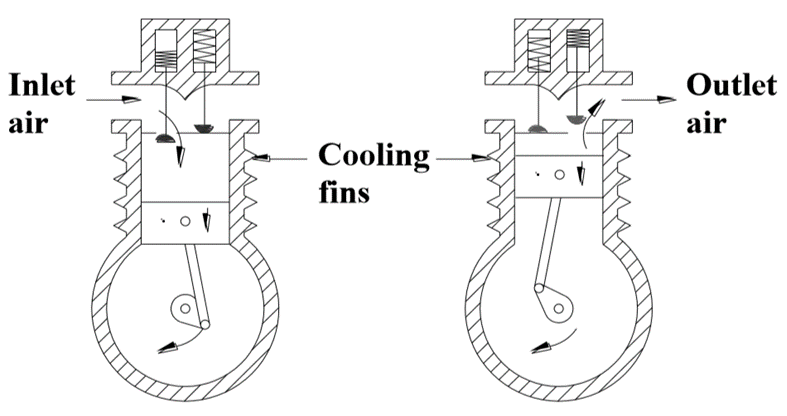

A3) Piston compressors are by far the most common type of compressor, and a basic single cylinder form is shown in Figure.

Fig. Single Cylinder Piston Compressor

Fig. Multi stage Piston Compressor

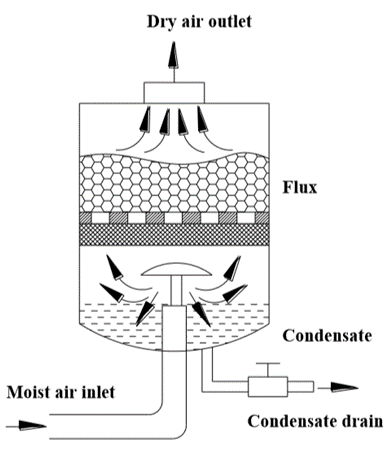

Q.4 Write a note on Air Filter

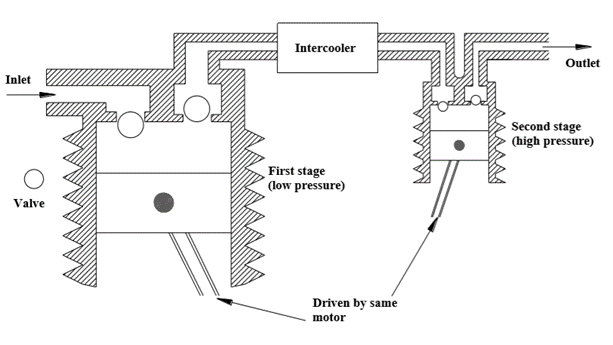

A4) The purpose of the air filter is to clean the compressed air of all impurities and any condensate it contains.

Function of air filters

Filters are available in wide range starting from a fine mesh wire cloth (which strains heavy foreign particles) to elements made of synthetic material (which removes very small particles)

Usually in line filter elements can remove contaminants in the 5-50 micron range.

The construction of typical cartridge type filter along with graphical symbols is shown in Figure

Fig. Typical Air Filter

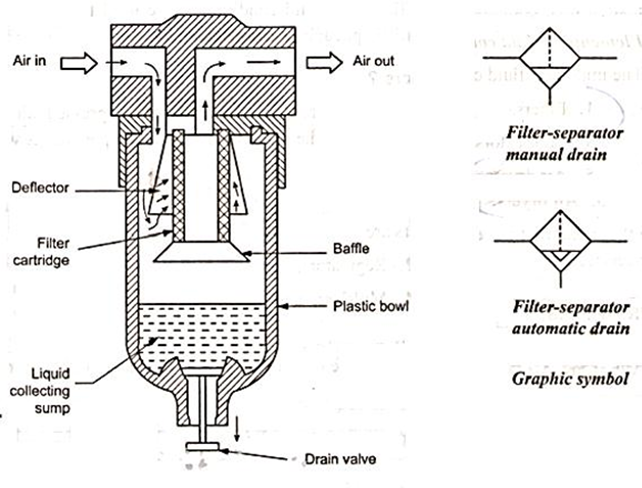

Q.5 What is the function of dryer? Explain any one in detail

A5) Function of dryer is to lower the dew point of the compressed air by removing the moisture from it. For simple applications, to remove excess humidity, we need simple after cooler, an air receiver, and a filter with condensate traps.

Types of Dryer

Generally four basic types of air dryers are used in Industries.

Absorption type dryer

Schematic diagram of absorption dryer is shown in Figure

Fig. Absorption Dryer

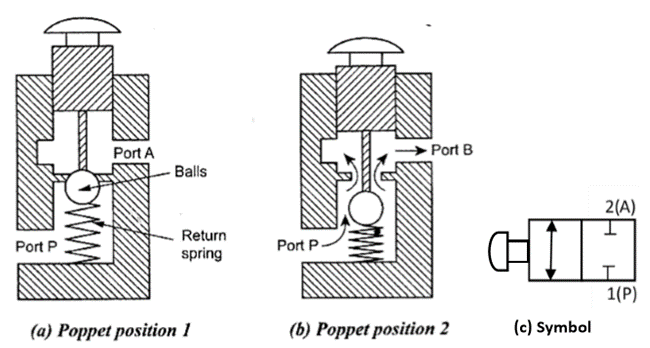

Q.6 Explain Ball seat DCV

A6) Ball seat valve.

Fig. 2/2 Ball seat poppet valve

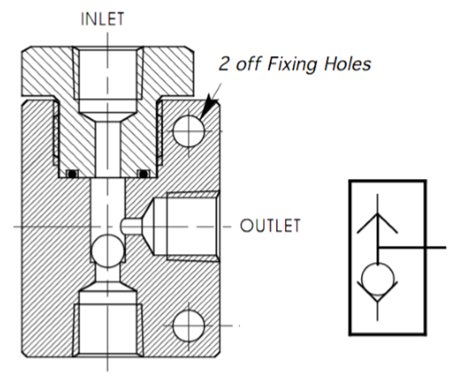

Q.7 What is shuttle Valve?

A7)

Fig. Shuttle valve

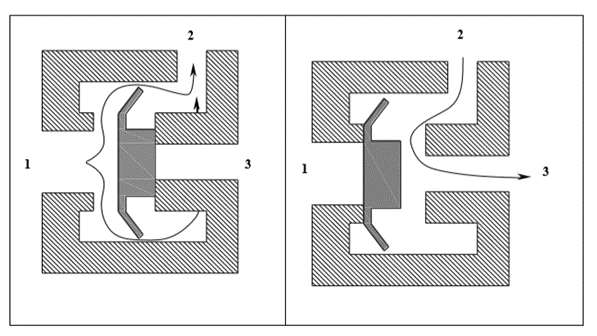

Q.8 Write a note on Quick Exhaust Valve with its application.

A8)

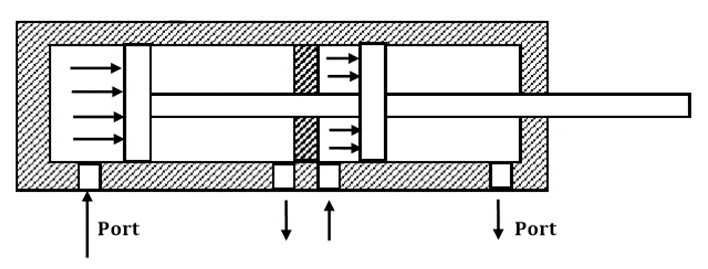

Fig. Quick Exhaust Valve

The construction and operation of a quick exhaust valve is shown in Figure.

Forward Motion: During forward movement of piston, compressed air is directly admitted behind the piston through ports 1 and 2 Port 3 is closed due to the supply pressure acting on the diaphragm. Port 3 is usually provided with a silencer to minimize the noise due to exhaust.

Return Motion: During return movement of piston, exhaust air from cylinder is directly exhausted to atmosphere through opening 3 (usually larger and fitted with silencer) .Port 2 is sealed by the diaphragm. Thus exhaust air is not required to pass through long and narrow passages in the working line and final control valve

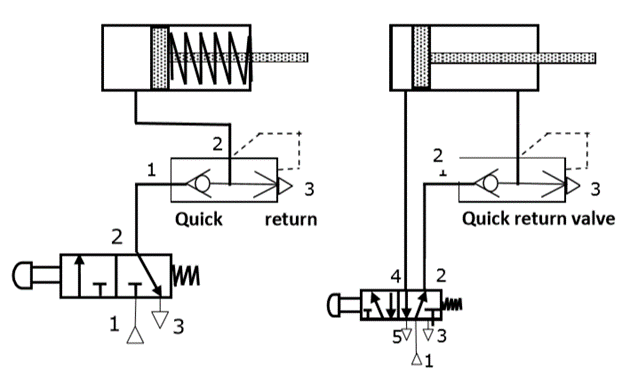

Typical applications of quick exhaust valves for single acting and double acting cylinders are shown in Figure.

Fig. Application of Quick Exhaust Valve

Q.9 Explain Tandem Cylinder in detail

A9)

Fig. Tandem Cylinder

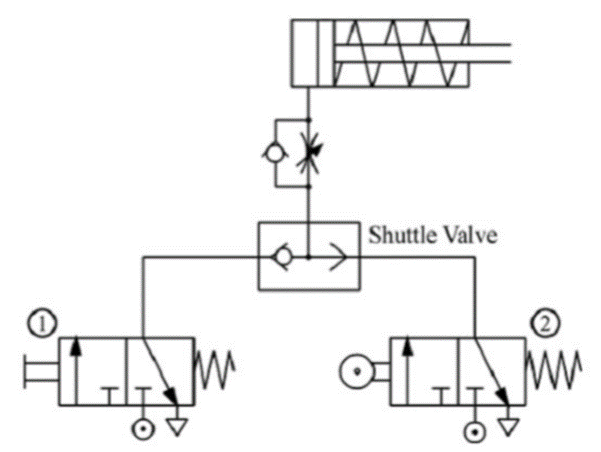

Q.10 Explain Pneumatic OR Valve

A10)

Fig. Control of a single acting cylinder using OR valve

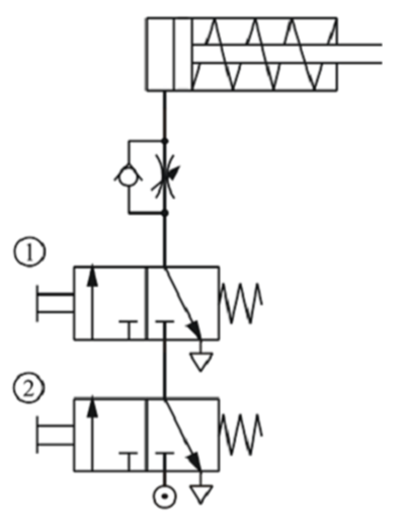

Q.11 Explain Pneumatic AND Valve

A11)

Fig. Control of a single acting cylinder using AND valve