UNIT-6

NON FERROUS MATERIALS

Q1) How do you classify nonferrous metals?

A1) Nonferrous material are those which have a metal other than iron as their main constituent such as copper, aluminium, brass, bronzer, tin, silver etc.

Non ferrous material classified in nine

Q2) What is brass? Describe the composition, properties and uses of important types of brasses?

A2) Brass is an alloy of copper and zinc, in proportions which can be varied to achieve varying mechanical and electrical properties.

The various types of brasses composition

Cu = 85%

Zn = 15%

2. Yellow brass :- Also known as Muntz metal, it contains

Cu = 60%

Zn = 40%

3. Admiralty brass :- it contains

Cu = 71%

Zn = 29%

Sn = 1%

4. Naval brass

Cu = 59%

Zn = 40%

Sn = 1%

5. Manganese Brass :-

Cu = 60%

Zn = 38%

Mn = 0.5%

Fe = 1.0%

Sn = 0.5%

Mechanical and other properties for industrial application:-

Copper:-

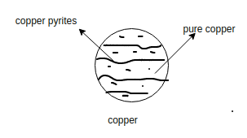

Copper is one of the most widely used non ferrous material in industry. It is extracted from area of copper such as copper glance, copper pyrites, malachite and azurite.

Properties:-

Munts metal is having high strength and high hot workability. It is having tensile strength 38 kg/m . The percentage elongation of this brass is 45%.

. The percentage elongation of this brass is 45%.

Application:- Yellow brass or munts metal is suitable for hot working by rolling extrusion on 4 stampings. It is utilized for making small various components of machines and electrical equipment such as bolts, rod, tubes, valves, and fuses and also making for pump parts, valves, taps, condensers tubes, sheet form for ship sheathing.

Tin bronze :-

Alloys consists of copper based material with the major alloy element being tin.

Properties

The percentage of tin provides high Mechanical properties, they passes stronger Mechanical properties.

Application

Their uses include heavy load, low-speed service application. Their alloys are the premier alloy for long life under heavy loads and used for piston pin and linkage bushing, valves guides. Many types of bearing including rolling mill, worm and pilot for the machine tool industry.

Beryllium bronze:-

Beryllium bronze is a copper bar alloy contains

Cu = 97.5%

Br = 2.5%

Applications

Beryllium bronze a is particularly suitable material for making springs, tubes, diaphragms and electrical contacts, heavy duty electrical switches, cams and bushings.

Properties:-

It possesses higher tensile strength than other bronze. It possesses excellent corrosion resistance. It is having high yield point and high fatigue limit. It is having good but cold assistance.

Q3) Explain the various types of aluminium alloys giving their composition, properties and uses?

A3) The aluminium may be easily alloyed with other elements like copper, magnesium, zinc, manganese, silicon, nickel to improve various properties.

LM5 :- The aluminium alloy confirms to BS 1490: 1988 LM5

Chemical composition

Copper = Max 0.1

Iron = Max 0.6

Zinc = Max 0.1

Titanium = Max 0.2

Magnesium = 3.0 – 6.0

Manganese = 0.3 – 0.7

Lead = 0.5 max.

Aluminium = remainder

Silicon = max 0.3

Tin = max 0.05

Nickel = max 0.1

Mechanical properties

Here we have explain some properties

Properties | Sand casting | Gravity casting |

0.2 % proof stress (N/ | 90 - 110 | 90 - 120 |

Tensile strength | 140 – 170 | 17 0-2 80 |

Elongation (%) | 3 | 5 |

Impact resistance 1200 (Nm) | 7.9 | 12.6 |

Brinell hardness | 50 – 70 | 60 - 70 |

Modulus of elasticity | 71 | 71 |

Shear strength | 140 | - |

Application:-

LM5 is used where very high resistance to corrosion from sea water or Marine atmosphere is required for equipment used for the manufacture of foodstuffs, cooking, utensils and chemical plant and application include, for example door furnitures, car fittings and trim. Similar aluminium casting. LM5 is mainly used for sand casting, for gravity the casting.

Duralumin:- It is unimportant wrought alloy. Its composition contains following chemical components

Copper = 3.5 - 4.5 %

Manganese = 0.4 – 0.7%

Magnesium = 0.4 days 0.7%

Aluminium = 94%

Properties

Duralumin can be very easily forged casted and worked because it possesses low melting point. It has high tensile strength, compare with mild steel combined with the characteristic lightness of aluminium. It is light in weight as compared to its strength in comparison to other metal.

Application

Duralumin is used in wrought conditions for forging, stampings, bars, sheets, tubes, bolts and rivals. It is also employed in surgical and orthopaedic work, non magnetic work and measuring instrument parts constructing work.

Y alloy:- Y alloy is also called copper aluminium alloy. The addition of copper to aluminium increase its strength and machinability. It contains following chemical compositions.

Copper = 3.5 – 4.5 %

Manganese = 1.2 – 1.7%

Nickel = 1.8 – 2.8%

Silicon, magnesium, iron = 0.6% each

Aluminium = 92.5%

Properties

The addition of copper in aluminium increases its strength and machinability. Y alloy can be easily cast and hot worked. Like aluminium alloy is heat treated and age hardened.

Hinduminum :- Is a common trade name of aluminium alloy. It is an alloy of aluminium, magnesium, manganese, chromium and silicon etc.

Property

Disallowed are strong and hard, easily cleaned, low cost than stainless steel having fine finish, having good scratch resistance.

Application

It is mainly used for manufacture anodized utensils. Utensils manufactured by this alloy are strong and hand easily clean.

Q4) Discuss the various type of nickel alloys?

A4) The important nickel alloy are monel metal, invan, nomonic.

Invan:- Invan also known generally as Fe Ni 36 is a nickel iron alloy notable for its uniquely low coefficient of thermal expansion. The name Invar comes from the word 'Invaniable' referring to its relative lack of expansion or contraction with temperature changes. It contain around 86% nickel and 64% iron.

Properties

Invar have a coefficient thermal expansion of about 1.2 while ordinary Steel have any around 11-15 ppm though display high dimensional stability over a range of temperature.

while ordinary Steel have any around 11-15 ppm though display high dimensional stability over a range of temperature.

Application

Invar is used where high dimensional stability is required such as precision instrument, clocks, siesmic creep gauge, television shadow mask frames, valves in engines and large aerostructure moulds

Inconel :- it contains

Ni = 80%

Cr = 14%

Fe = 6%

Properties

it has high resistance to corrosion and oxidation at elevated temperature. It can be readily cold worked and hot worked. But does not respond to heat treatment. It contains high Mechanical properties, Coupled corrosion and resistance property. It can be cast, forged, rolled and cold down. Its specific gravity is 8.55 and melting point 1395 degree Celsius. It's Brinell hardness is about 160 BHN.

Application

It is used for making springs, exhaust main fold of aircraft engines, machinery for food processing industries especially milk and milk products. It is widely used for processing uranium and for sheeting for high temperature heating element.

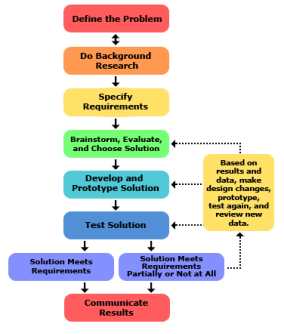

Q5) How will you select the suitable engineering materials for particular applications?

A5) Factors that should be considered before selecting a material for engineering include:

Importance of Material Selection in Engineering Design Process

Q6) Discuss the properties and uses of following non ferrous metal

A6) Copper:-

Copper is one of the most widely used non ferrous material in industry. It is extracted from area of copper such as copper glance, copper pyrites, malachite and azurite.

Properties:-

Munts metal is having high strength and high hot workability. It is having tensile strength 38 kg/m . The percentage elongation of this brass is 45%.

. The percentage elongation of this brass is 45%.

Application:- Yellow brass or munts metal is suitable for hot working by rolling extrusion on 4 stampings. It is utilized for making small various components of machines and electrical equipment such as bolts, rod, tubes, valves, and fuses and also making for pump parts, valves, taps, condensers tubes, sheet form for ship sheathing.

Tin:-

Alloys consists of copper based material with the major alloy element being tin.

Properties

The percentage of tin provides high Mechanical properties, they passes stronger Mechanical properties.

Application

Their uses include heavy load, low-speed service application. Their alloys are the premier alloy for long life under heavy loads and used for piston pin and linkage bushing, valves guides. Many types of bearing including rolling mill, worm and pilot for the machine tool industry.

Aluminium:-

The aluminium may be easily alloyed with other elements like copper, magnesium, zinc, manganese, silicon, nickel to improve various properties

Properties

Application

Aluminium is used in a huge variety of products including cans, foils, kitchen utensils, window frames, beer kegs and aeroplane parts.

Zinc:

Properties: some Properties are

Density 7.11 g.cm-3 at 20°C

Melting point 420 °C

Boiling point 907 °C

Vanderwaals radius 0.138 nm

Ionic radius 0.074 nm (+2)

Isotopes 10

Application

Most zinc is used to galvanise other metals, such as iron, to prevent rusting. Galvanised steel is used for car bodies, street lamp posts, safety barriers and suspension bridges

Large quantities of zinc are used to produce die-castings, which are important in the automobile, electrical and hardware industries. Zinc is also used in alloys such as brass, nickel silver and aluminium solder.

Zinc oxide is widely used in the manufacture of very many products such as paints, rubber, cosmetics, pharmaceuticals, plastics, inks, soaps, batteries, textiles and electrical equipment. Zinc sulfide is used in making luminous paints, fluorescent lights and x-ray screens

Lead:

Properties

Lead is a bluish-white lustrous metal. It is very soft, highly malleable, ductile, and a relatively poor conductor of electricity. It is very resistant to corrosion but tarnishes upon exposure to air.

Application

Lead is still widely used for car batteries, pigments, ammunition, cable sheathing, weights for lifting, weight belts for diving, lead crystal glass, radiation protection and in some solders. ... It is also sometimes used in architecture, for roofing and in stained glass windows.

Nickel: Invan:- Invan also known generally as Fe Ni 36 is a nickel iron alloy notable for its uniquely low coefficient of thermal expansion. The name Invar comes from the word 'Invaniable' referring to its relative lack of expansion or contraction with temperature changes. It contain around 86% nickel and 64% iron.

Properties

Invar have a coefficient thermal expansion of about 1.2 while ordinary Steel have any around 11-15 ppm though display high dimensional stability over a range of temperature.

while ordinary Steel have any around 11-15 ppm though display high dimensional stability over a range of temperature.

Application

Invar is used where high dimensional stability is required such as precision instrument, clocks, siesmic creep gauge, television shadow mask frames, valves in engines and large aerostructure moulds

Q7) What is age hardening and explain also advantage and application?

A7) Age hardening also known as precipitation hardening is a type of heat treatment that is used to impart strength to metals and their alloys. It is called precipitation hurting as it makes use of solid impurities or precipitate for the strengthening process. The metal is aged by either heating it or keeping It stored at lower temperature so that precipitates are formed.

Advantage:-

Some of the advantages that each hardening offers

Application

Some of the application of age hardening are:-

Q8) What is bearing alloy and describe the composition, properties and explain application.

A8) Bearing alloys form a special group of materials which have found wide use in the manufacture of slide bearing bushings. The bearing alloys used in commercial practice include cast irons, bronzes, and alloys based on tin, lead, zinc and aluminium. The most common alloys are those of tin and lead. They are used for lining slide bearings in cars, wagons, turbines, mills and other devices.

A bearing alloy commonly possesses good wearing quality, low coefficient of friction, high thermal conductivity, good casting qualities, non corrosive properties, ability to withstand high pressure and impact low shrinkage after coating and less cost various bearing metal are

Properties

These alloys are possess

(a) excellent corrosion resistance

(b) fair conformability to journal

(c) good ability to embed dirt

(d) good seizure resistance

(e) good thermal conductivity

Q9) Describe the Cobalt alloy properties, application and also composition?

A9) Cobalt is a chemical element with symbol Co and atomic number 27.

Cobalt and its alloy:-

Cobalt based super alloys have historically consumed most of the Cobalt produced. Here we have discussed.

1) Stellite alloy: - Stellite alloys are a group of Cobalt chromium “super alloys” consisting of complex carbides in an alloy matrix. Predominantly design for high wear resistance and super chemical and corrosion performance in hostile environment therefore it is possible to group stellite alloys as follows:-

High carbon= design for high wear applications

Low carbon = for high temperature

Loss carbon/ higher chromium to combat corrosion

It consists of

Cobalt = 57%

Chromium = 28.3 %

Tungsten = 11.30%

Carbon = 2.3%

Silicon = 1.2%

Iron = 1%

Nickel = 1%

Other = 1.50%

Properties:- The properties of steel alloys are

Property | Metric | Imperial |

Density | 8.69 | 0.314 Ib/i |

Hardness Rockwell | 50 - 58 | 50 – 58 |

Tensile strength | 1195 MPa | 173 Ksi |

Yield strength | 1050 MPa | 152 Ksi |

Modulus of elasticity | 2304 MPa | 33.4×106 Psi |

Application:-

Saw teeth, hand facing and acid resistance, machine parts, poppet valves, seats and exhaust valve of of engine, M2HB machine gear and machine gun barrel, turning tool for lathe.

1) Alnico:- The composition of alnico alloys is typically

Aluminium= 8-12%

Co = 5-24%

Ni =15-26%

Properties:-

Alnico alloys can be magnetized to produce strong magnetic field. It has a high coercivity, thus making strong permanent magnets. Alnico alloys have some of the highest Curie temperature off any magnetic material, they are only magnets that have useful magnetism even when heated red hot. The property as well as its brittleness and high melting point.

Application

Alnico magnets are widely used in industrial and application where strong permanent magnets are needed. Examples are electric motor, electric guitar pickups, microphones, sensors, magnetron tubes and cow magnets.

Q10) What is titanium alloy? Describe the composition, properties and uses.

A10) Titanium alloy are alloys that contain a mixture of titanium and other chemical components. Such alloy have very high tensile strength and toughness. It has a chemical composition of 6% aluminum, 4% vanadium, 0.25% (maximum) iron, 0.2% (maximum) oxygen, and the remainder titanium. Here we discuss two main titanium alloy

Properties

Generally it contain predominant Lee Alpha phase and temperature well above 40 degree Celsius. Alpha rich boy are more resistance to high temperature creep and Alpha alloys exhibit little strengthening from heat treatment and they have good workability.

Uses: Titanium is as strong as steel but much less dense. It is therefore important as an alloying agent with many metals including aluminium, molybdenum and iron. These alloys are mainly used in aircraft, spacecraft and missiles because of their low density and ability to withstand extremes of temperature. They are also used in golf clubs, laptops, bicycles and crutches.

Power plant condensers use titanium pipes because of their resistance to corrosion. Because titanium has excellent resistance to corrosion in seawater, it is used in desalination plants and to protect the hulls of ships, submarines and other structures exposed to seawater.

Titanium metal connects well with bone, so it has found surgical applications such as in joint replacements (especially hip joints) and tooth implants.

The largest use of titanium is in the form of titanium(IV) oxide. It is extensively used as a pigment in house paint, artists’ paint, plastics, enamels and paper. It is a bright white pigment with excellent covering power. It is also a good reflector of infrared radiation and so is used in solar observatories where heat causes poor visibility.

Titanium(IV) oxide is used in sunscreens because it prevents UV light from reaching the skin. Nanoparticles of titanium(IV) oxide appear invisible when applied to the skin.