Unit – 4

IC Engine Testing and Emission

Q1) What is the Purpose of Testing of an I.C. Engine.

A1)

Purpose of Testing an I.C. Engine:

In general, the purpose or significance of testing an I.C. engine is to determine the following:

(i) To determine rated power output with respect to the fuel consumption in Kg per

Kw-hr of brake power output.

(ii) To determine the mechanical and thermal efficiencies of the engine.

(iii) To see the performance of the engine when loaded at different loads.

(iv) To determine the quantity of lubricating oil required per bp Kw hr.

(v) To determine the quantity of cooling water required per bp Kw hr.

(vi) To determine the overload carrying capacity of the engine.

(vii) To prepare the heat balance sheet of the engine.

Q2) Explain the Measurement of friction power by Willan’s line method.

A2)

Measurement of friction power by Willan’s line method:

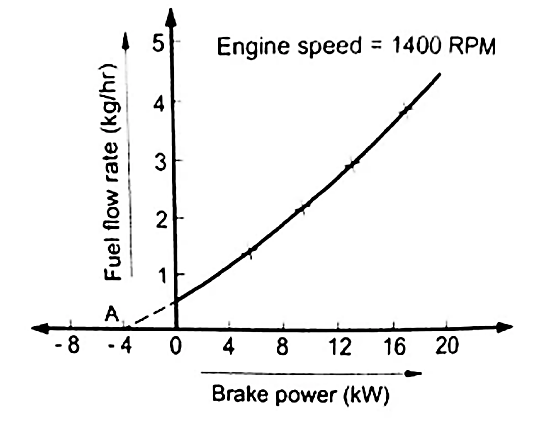

Willan’s line method is also known as the fuel rate extrapolation method. In this method, we draw a graph where we take brake power (B.P) (kW) on X-axis and fuel flow rate (kg/hr) on Y-axis on a condition that the engine is running at a constant speed.

As shown in the figure, the graph is anticipated back to zero fuel flow rate of zero fuel where it cuts at point A on the negative X-axis.

Point A on the negative X-axis shows the friction power at the same speed on the engine. When break power becomes zero, then fuel consumption at the same power represents the fuel consumed to overcome the friction loss of the engine.

As per the graph, variation in the fuel flow rate and brake power is linear. It results in the anticipation of the straight part of the main curve as a negative crossing on the X-axis at zero fuel flow rate will represent the friction power (F.P).

Limitations of Willan’s line method:

Q3) Explain the measurement of Mean effective pressure.

A3)

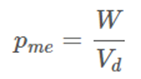

Mean effective pressure is a quantity relating to the operation of a reciprocating engine and is a valuable measure of an engine's capacity to do work that is independent of engine displacement.

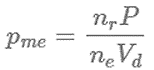

where:

pme – mean effective pressure

W – work performed in a complete engine cycle

Vd – engine (cylinder) displacement

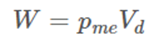

we can write the expression of the engine work as:

There is also a direct relationship between the power of the engine and the work produced:

where:

nr – number of crankshaft rotations for a complete engine cycle (for 4-stroke engine nr = 2)

P – engine power

ne – engine speed

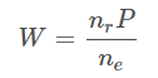

The mean effective pressure function of power and engine speed:

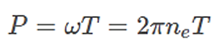

Power is the product between torque and speed:

we get the expression of mean effective pressure function of engine torque:

Q4) Explain the various types of efficiency.

A4)

Brake thermal efficiency is defined as break power of a heat engine as a function of the thermal input from the fuel. It is used to evaluate how well an engine converts the heat from a fuel to mechanical energy

The thermal efficiency is a dimensionless performance measure of a device that uses thermal energy, for example engine, a steam turbine, a steam engine, a boiler, a furnace, etc., Thermal efficiency indicates the extent to which the energy added by work is converted to net heat output.

Mechanical efficiency is the measure of effectiveness of a machine's energy and power that is input into the device into an output that makes force and movement. Mechanical advantage by comparing the input and output force you can find the advantage of a machine

Volumetric efficiency in internal combustion engine engineering is defined as the ratio of the mass density of the air-fuel mixture drawn into the cylinder at atmospheric pressure (during the intake stroke) to the mass density of the same volume of air in the intake manifold.

Q5) Explain the Flame Ionization Detector (FID).

A5)

Flame Ionization Detector (FID)

Q6) Explain the Chemiluminescent Analyzer.

A6)

Chemiluminescent Analyzer

[A] + [b] → [◊] → [products] + light

[A], [b]: reactants

[◊]: Excited intermediate.

For example, if [A] is luminol and [B] is hydrogen peroxide in the presence of a suitable catalyst we have:

Luminol + H2O2 →3-APA [◊] →3-APA + light

Where:

Q7) What do you understand by Heat balance sheet. Explain in detail.

A7)

Heat balance sheet

mf = mass of fuel supplied in kg/min.

c = calorific value of fuel in kJ/kg

then heat supplied = mf  c

c

B. Heat output comprises of heat expenses,

Heat expenses are

brake power of the engine,

B.P. =  in watts (neglecting diameters of ire rope)

in watts (neglecting diameters of ire rope)

B.P. =  in watts (considering diameters of ire rope)

in watts (considering diameters of ire rope)

b. heat rejected to the cooling water

mw = mass of cooling water supplied (in kg/min)

Cpw = specific heat of water which may be taken as 4.187 (in KJ/kg.k)

Tw1 = Inlet temperature (in 0 C or K)

Tw0 = outlet temperature (in 0 C or K)

mw  Cpw

Cpw  (Tw0 - Tw1) (in KJ/min)

(Tw0 - Tw1) (in KJ/min)

c. Heat carried away by exhaust gases

meg = mass of exhaust gasses in kg/min

Cpeg= specific heat exhaust gases in kj/kg.k

T = Rise in temperature in 0 C or K

T = Rise in temperature in 0 C or K

Then heat carried away by exhaust gases

= meg Cpeg T in KJ/min

T in KJ/min

= meg Cpeg(Teg – Ta)

Where Teg = temperature of exhaust gases

Ta = atmospheric room temperature

d. Unaccounted heat

Heat input | KJ/min | % | Heat output | KJ/min | % |

|

| 100% |

|

|

|

|

|

| b. Heat rejected to cooling water |

|

|

|

|

| c. Heat carried away by exhaust gases |

|

|

|

|

| d. Unaccounted heat |

|

|

Q8) Explain the Measurement of friction power by Morse test.

A8)

Measurement of friction power by Morse test:

I1+I2+I3+I4 = (BP)engine +(F1+F2+F3+F4)

Where I1, I2, I3 and I4 – Indicated power of four cylinders

(BP)engine – Brake power of engine when all cylinders are working

F1, F2, F3, F4 – Frictional power of all four cylinders

Then the first cylinder is cut off by short circuiting spark plug in case S.I. engine (or cutting fuel supply in case C.I. engine). This causes the speed to drop due to non-firing of first cylinder. It should be noted that although first cylinder is not producing power still it is moving up and down so its frictional power must be considered. This speed is once again maintained to its original value by reducing load on the engine

I2+I3+I4 = (BP)2,3,4 +(F1+F2+F3+F4)

Where (BP)2,3,4 – Brake power of 2,3 & 4 cylinders only.

Repeat the above procedure for remaining cylinders and calculate I.P. of the engine.

Cylinder 2 is cut off – I1+I3+I4 = (BP)1,3,4 +(F1+F2+F3+F4)

Cylinder 3 is cut off – I1+I2+I4 = (BP)1,2,4 +(F1+F2+F3+F4)

Cylinder 4 is cut off – I1+I2+I3 = (BP)1,2,3 +(F1+F2+F3+F4)

I.P. of cylinder 1 is calculated as,

I1 = (BP)engine – (BP)2,3,4

Similarly, I2, I3 and I4 is calculated as follows

I2 = (BP)engine – (BP)1,3,4

I3 = (BP)engine – (BP)1,2,4

I4 = (BP)engine – (BP)1,2,3

Total Indicated power of engine = I.P.

IP = I1+I2+I3+I4

Frictional power of engine

FP = IP – (BP) engine.

Q9) Define the following:

A9)

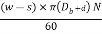

Brake Power (bp):

Brake Power, bp = (W−S) x 2𝝅 (𝑫+𝒅𝟐) x N 𝟔𝟎𝒙𝟏𝟎𝟎𝟎 kW

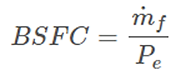

Brake specific fuel consumption:

Brake specific fuel consumption (BSFC) is a parameter that reflects the efficiency of a combustion engine which burns fuel and produces rotational power (at the shaft or crankshaft).

Indicated power:

The indicated power of an I.C engine is the total power developed within the cylinder in one complete cycle neglecting any losses. It is the sum total of the brake power and the friction power of an engine.

Q10) Explain the Non-Dispersive Infra-red (NDIR) Analyzer.

A10)

Non-Dispersive Infra-red (NDIR) Analyzer: