CT

UNIT - 6SPECIAL CONCRETE AND DURABILITY OF CONCRETE Q1) Explain light weight concrete A1)Lightweight concrete may be described as a sort of concrete which incorporates an increasing agent in that it will increase the quantity of the combination whilst giving extra characteristics which includes nailbility and lessened the useless weight. It is lighter than the traditional concrete. The use of light-weight concrete has been broadly un fold throughout international locations which includes USA, United Kingdom and Sweden. The essential specialties of light-weight concrete are its low density and thermal conductivity. Its blessings are that there may be a discount of useless load, quicker constructing quotes in creation and decrease haulage and managing costs. Lightweight concrete keeps its huge voids and now no longer forming laitance layers or cement movies while located at the wall. This study became primarily based totally at the overall performance of aerated light-weight concrete. However, enough water cement ratio is essential to provide good enough concord among cement and water. Insufficient water can purpose loss of concord among debris, for that reason loss in energy of concrete. Likewise, an excessive amount of water can purpose cement to run off mixture to shape laitance layers, finally weakens in energy. Lightweight concrete has been used because the eighteen centuries through the Romans. The software at the ‘The Pantheon’ wherein it makes use of pumice mixture with inside the creation of solid in-situ concrete is the evidence of its usage. In USA and England with inside the overdue 19th century, clinker became used of their creation as an example the ‘British Museum’ and different low price housing. The light-weight concrete became extensively utilized in creation at some point of the First World War. The United States used particularly for shipbuilding and urban blocks. The foamed blast furnace-slag and pumice mixture for block making had been added in England and Sweden round 1930s. Nowadays with the development of technology, light-weight concrete expands its makes use of. For example, with inside the shape of per lite with its top notch insulating characteristics. It is broadly used as loose-fill insulation in masonry creation wherein it complements hearth place ratings, reduces noise transmission, does now no longer rot and termite resistant. It is likewise used for vessels, roof decks and different applications. Materials utilized in Light weight concrete:Lightweight concrete may be produced through introducing: gassing retailers which includes aluminum powder or foaming retailers, light-weight mineral mixture which includes perlite, vermiculite, pumice, elevated shale, slate, and clay, or plastic granules as mixture Properties of Light weight concrete:Low Density Fire Resistance Sound Insulation Durability Thermal insulation Quality Control Low DensityThe density of concrete varies from three hundred to 1200 kg/m³. The lightest grade appropriate for insulation proposed whilst the heavier grades with good enough energy appropriate for structural applications. The low density of cell concrete makes it appropriate for precast ground and roofing devices which can be smooth to deal with and shipping from the manufacturing unit to the sites. Fire ResistanceLightweight concrete has outstanding hearth place-resisting properties. Its low thermal conductivity makes it appropriate for protective every other established shape the outcomes of fir Sound InsulationSound insulation in cell concrete is typically now no longer as suitable as in dense concrete. DurabilityAerated concrete is handiest barely alkaline. Due to its porosity and coffee alkalinity. It does now no longer deliver rust safety to metallic that's supplied through dense as compared concrete. Thermal insulationThe insulation fee of light-weight concrete is set 3 to 6, instances that of bricks and approximately ten instances of concrete. When a two hundred mm thick wall of aerated concrete of density 800 kg/ m3 has the identical diploma of insulation as a four hundred mm thick wall of density 1600 kg/ m3. Quality ControlBetter first-rate manipulate exercised withinside the creation of a shape with light-weight concrete merchandise because of using manufacturing unit-made devices. Types of Light weight Concrete:Lightweight aggregate concrete:Lightweight aggregate concrete is referred to as an LWA. In the early 1950s, using light-weight concrete blocks familiar withinside the UK for the load-bearing internal leaf of hollow space walls. Soon thereafter the improvement and manufacturing of a brand new sort of synthetic LWA made it viable to introduce LWC of excessive energy, appropriate for structural work. These advances inspire the structural use of LWA concrete. Particularly wherein the want to lessen weight in a shape became an critical attention for layout or for the economy. Aerated Concrete:Aerated concrete has the bottom density, thermal conductivity, and energy. Like timber, it is able to be sawn, screwed and nailed, however there are non-combustible. For works in-situ, the standard strategies of aeration are through blending in stabilized shape or through whipping air in with the useful resource of an air-entraining agent. No fines concrete:The time period no-fines concrete typically way concrete composed of cement and a coarse (9-19) aggregates handiest and the product so fashioned has many uniformly disbursed voids for the duration of its mass. Ordinary light-weight concrete organized from a binder, water best and coarse mixture with complete filling voids among the huge debris. Low Sand concrete, wherein the voids among the coarse mixture handiest partly packed with the paste. It additionally referred to as an opening graded concrete and dealt separately. In this example on best mixture use. Coarse debris of the mixture are coved through a skinny layer of cement, paste and the voids among them stay empty. It is referred to as as no concrete. Aerated concrete crafted from a binder, water, best and coarse mixture, and a blowing agent which reduced the density of concrete. Q2) Explain polymer modified concrete A2)Concrete with polymers embedded during mixing to transform the hard concrete structures of polymer modified cement concrete (PMC). Polymers were added to the concrete mixture either in the form of a liquid emulsion or in a dispersed form. This is to develop the following concrete elements: Increase and strength of concrete structure Impact resistance Abrasion Resistance Strength and resistance to aggressive liquids The bond between old and old concrete Converted cement polymer cement is a compound obtained by the incorporation of a polymeric substance into a concrete. This is done during mixing. The polymers included in this section should not necessarily interfere with the hydration process. Since most polymers do not dissolve in water, their additions can only be done by means of emulsion or dispersion or in the form of latex. Blends that are built and then installed in the required condition by the standard construction method. Later treatments were performed similar to conventional concrete treatments. Hydrated cement and polymer film are formed as a result of the treatment of the polymeric substance forming an inert matrix that binds the aggregate. Polymeric building materials in the form of lattices and pre polymers can be added to convert cement concrete. The number of polymers required for polymer-converted concrete is very small. This range ranges from 1 to 4% in compound size. Polymer concrete is the least expensive. PMC processing is found to be very simple. In terms of PMC concrete slabs, it is not a sign. Pregnant polymer concrete is better available in mechanical properties compared to refined polymer concrete. Types of Polymer Modified Concrete (PMC)Depending on the type of converter used, modified polymer concrete can be divided into the following types:Latex-Modified Cement Concrete Modified Pre-Polymer Concrete Latex-Modified Cement ConcreteMilk white lattices as a suspension containing very small particles of polymer, suspended in water with the help of emulsifiers and stabilizing agents. It contains about 50% solid polymer in bulk. Both elastomeric and glass-based polymers are employed in concrete cement lattices. These provide a high modulus of durability, high strength and a low level of rust corrosion. Latex additives can be stored in sufficient exposure which helps the mixture to be protected from exposure to cold and heat. If the mixture stored on the side is exposed to sunlight, it should be well covered with a suitable protective clothing. The inserted temperature to be maintained must be below 85F. Natural latex, acrylonitrile-butadiene, neoprene and rubber latex are some of the most widely used latex elastomeric latex. Glass polymers have a large module for durability, strength and meet an unacceptable type of failure. Common examples are poly vinylidene chloride, acrylic polymers, polyvinyl acetate and styrene butadiene copolymer latex. Poly vinylidene copolymer is used in uncoated concrete systems due to the presence of residual chlorine that causes corrosion. Curing moisture of the compound for a period of one to seven days creates a perfect therapeutic heat. This is followed by a dry treatment later. Within 28 days of treatment, the modified latex concrete would have regained its final strength. Pre Polymers-Modified Cement ConcreteA polyester-based based system, epoxy system and furan system etc are used for this. The strength development of this type of PMC is 50-100% higher than conventional concrete. Its adhesive material is beautiful and has strong, durable structures. The tensile strength and modulus of rupture is more than double that of conventional concrete. The formation of small cracks is small in the case of pre-polymer-modified concrete. There is a low level of water cement and the filling of pores inside the pre-polymer concrete which will help to improve the durability of the concrete compared to conventional concrete. However, the cost of polymer does not account for the strength of the polymer reinforced concrete. Properties of Polymer Modified ConcreteThe features of Polymer concrete are described below:The addition of polymers makes concrete mixing more efficient. This can reduce the amount of water added to the concrete mix. The crushing power of concrete is increasingly the use of polymer in concrete. This is because the polymer reduces the water content of the water which also increases the crushing power. The bond between the merger and the matrix has been improved. Polymer modification increases the flexibility of concrete. Modified polymer concrete contains at least 3% more air compacted than plain concrete. This additional amount of ventilation will reduce the flexibility of the concrete (PMC). The addition of polymer increases the setting time of the concrete. Concrete resistance to abrasion increases with the use of polymer. Cold fractures and melting of concrete structure are enhanced by the polymer conversion. The intrusion of chlorine ions and other harmful substances is prohibited. The PMC finds high resistance against such undesirable effects. PMC gains high shear bond strength. The adhesive material of refined polymer concrete is highly comparable to conventional concrete. This gains higher strength and flexibility compared to conventional concrete. Applications for Polymer Modified ConcreteModified polymer concrete can be used to repair and replace damaged old concrete. The construction of the floor in refrigerated refrigerators - food gets a good application. This is due to the high levels of ice and melting of the PMCs. With the construction of factories on the ground were the chances of the chemical and oil cracks occurring more frequently. Preparation of steel bridge and shipping areas. The structure of concrete is concentrated in large volumes of salt to extract liquids. Ceramic tile reinforcement for concrete. Q3) Explain concept of fiber reinforced concrete A3)Fiber Reinforced concrete:Fiber Reinforced Concrete is composite cloth which include fibrous cloth which will increase its structural integrity. It consists of combinations of cement, mortar or concrete and discontinuous, discrete, uniformly dispersed appropriate fibers. Fibers are normally utilized in concrete to govern cracking because of plastic shrinkage and to drying shrinkage. They additionally lessen the permeability of concrete and consequently lessen the bleeding of water. Advantages of Fiber-strengthened concrete:Fibers strengthened concrete can be beneficial in which excessive tensile power and decreased cracking are proper or whilst traditional reinforcement cannot be placed. It improves the effect power of concrete, limits the crack boom and ends in a extra stress potential of the composite cloth. For commercial projects, macro-artificial fibers are used to enhance concrete’s sturdiness. Made from artificial substances, those fibers are lengthy and thick in length and can be used as a substitute for bar or material reinforcement. Adding fibers to the concrete will enhance its freeze-thaw resistance and assist maintain the concrete sturdy and appealing for prolonged periods. Improve blend cohesion, enhancing pump ability over lengthy distances. Increase resistance to plastic shrinkage in the course of curing. Minimizes metallic reinforcement requirements. Controls the crack widths tightly, consequently enhancing sturdiness. Reduces segregation and bleed-water. FRC, longevity is ready 10 to forty instances that of undeniable concrete. The addition of fibers will increase fatigue power. Fibers boom the shear potential of strengthened concrete beams. Application of Fiber-strengthened concrete:The programs of fiber strengthened concrete rely on the applicator and builder in taking gain of the static and dynamic traits of the cloth. Some of its vicinity of software is-Runway Aircraft Parking Pavements Tunnel Lining Slope Stabilization Thin Shell Walls Pipes Manholes Dams Hydraulic Structure Elevated decks Roads Bridges Warehouse floors Fiber Types:Fibers for concrete are to be had in exclusive sizes and shapes. The essential elements affecting the function of fiber-strengthened concrete are a water-cement ratio, percent of fibers, diameter and duration of fibers. Given beneath are exclusive varieties of fiber-strengthened concrete utilized in production.Steel Fiber Reinforced Concrete:Steel fiber is a metallic reinforcement. A sure quantity of metallic fiber in concrete can motive qualitative modifications in concrete’s bodily property. It can significantly boom resistance to cracking, effect, fatigue, and bending, tenacity, sturdiness, and others. For enhancing lengthy-time period behavior, improving power, longevity, and strain resistance, SFRC is being utilized in systems which includes flooring, housing, precast, bridges, tunneling, heavy-responsibility pavement, and mining. The varieties of metallic fibers are described via way of means of ASTM A820 are, Type I: cold-drawn cord, Type II; reduce sheet, Type III: melt-extracted, Type IV: mill reduce and Type V: changed cold-drawn cord Polypropylene Fiber Reinforced (PFR) Concrete:Polypropylene fiber strengthened concrete is likewise referred to as poly propene or PP. It is a artificial fiber, converted from propylene, and utilized in loads of programs. These fibers are normally utilized in concrete to govern cracking because of plastic shrinkage and drying shrinkage. They additionally lessen the permeability of concrete and consequently lessen the bleeding of water. Polypropylene fiber belongs to the institution of poly olefins and is partly crystalline and non-polar. It has comparable homes as poly ethylene, however it's far tougher and greater warmth resistant. It is a white rugged cloth with excessive chemical resistance. Polypropylene is made from propylene fuel o line with inside the presence of a catalyst which includes titanium chloride. Polypropylene fiber shows accurate warmth-insulating homes and is especially immune to acids, alkalies, and natural solvents. Glass Fiber Reinforced Concrete:Glass fiber strengthened concrete is a cloth which include extraordinarily first-rate fibers of glass. Glass fiber has kind of similar mechanical homes to different fibers which includes polymers and carbon fiber. Although now no longer as inflexible as carbon fiber, it's far tons less expensive and notably much less brittle whilst utilized in composites. Glass fibers are consequently used as a reinforcing agent for lots polymer merchandise; to shape a totally sturdy and comparatively light-weight fiber-strengthened polymer (FRP) composite cloth known as glass-strengthened plastic (GRP), additionally popularly referred to as “fiberglass”. This cloth incorporates very little air or fuel o line, is denser, and is a mile’s poorer thermal insulator than is glass wool. Polyester fibers:Polyester fibers are utilized in fiber-strengthened concrete for commercial and warehouse floors, pavements and overlays and precast merchandise. Polyester micro- and macro-fibers are utilized in concrete to offer advanced resistance to the formation of plastic shrinkage cracks as opposed to welded cord material and to decorate longevity and the capacity to supply structural potential whilst well designed, respectively. Polyester micro- and macro-fibers are utilized in concrete to offer advanced resistance to the formation of plastic shrinkage cracks as opposed to welded cord material and to decorate longevity and the capacity to supply structural potential whilst well designed, respectively. Carbon fibers:Carbon fibers are fibers approximately 5–10 micrometers in diameter and composed in general of carbon atoms. Carbon fibers have numerous benefits such as excessive stiffness, excessive tensile power, low weight, excessive chemical resistance, excessive-temperature tolerance and coffee thermal expansion. Carbon fibers are normally mixed with different substances to shape a composite. When impregnated with a plastic resin and baked it bureaucracy carbon-fiber-strengthened polymer (frequently known as carbon fiber) which has a totally excessive power-to-weight ratio, and is extraordinarily inflexible even though particularly brittle. Carbon fibers also are composited with different substances, which includes graphite, to shape strengthened carbon composites, that have a totally excessive warmth tolerance. Macro artificial fibers:Macro artificial fibers are crafted from a mix of polymers and have been at the beginning advanced to offer an opportunity to metallic fibers in a few programs. Initially, they have been diagnosed as a ability opportunity to metallic fibers in sprayed concrete, however growing studies and improvement confirmed that that they'd a function to play with inside the layout and production of ground-supported slabs and a huge variety of different programs. They are specifically appropriate for presenting nominal reinforcement in competitive environments, which includes marine and coastal systems, as they do now no longer go through the troubles of staining and spalling which could end result from the corrosion of metallic. Besides, due to the fact they may be non-conducting, they had been utilized in tram and mild railway developments. Micro-artificial fibers:Micro-artificial fibers offer advanced resistance to the formation of plastic shrinkage cracks as opposed to welded cord reinforcement, they may be not able to offer any resistance to similarly crack width openings due to drying shrinkage, structural load or different sorts of strain. However, those merchandise need to be frequently laid out in any form of concrete to enhance cracking resistance, spall protection, freeze-thaw sturdiness and enhance the homogeneity of concrete in the course of placement. Natural fibers:The herbal fiber is without delay available from an animal, vegetable, or mineral supply and convertible into nonwoven fabric which includes felt or paper or, after spinning into yarns, into woven cloth. A herbal fiber can be similarly described as an agglomeration of cells wherein the diameter is negligible in evaluation with the duration. Although nature abounds in fibrous substances, in particular cellulosic kinds which includes cotton, wooden, grains, and straw. The use of herbal fibers in making concrete is usually recommended in view that numerous varieties of those fibers are to be had domestically and are plentiful. The concept of the use of such fibers to enhance the power and sturdiness of brittle substances isn't new; for example, straw and horsehair are used to make bricks and plaster. Natural fibers are appropriate for boosting concrete and are without difficulty to be had in growing countries. Cellulose fibers:Cellulose fibers are made with ethers or esters of cellulose, which may be acquired from the bark, wooden or leaves of plants, or different plant-primarily based totally cloth. In addition to cellulose, the fibers may comprise hemi cellulose and lignin, with exclusive possibilities of those additives changing the mechanical homes of the fibers. The predominant programs of cellulose fibers are with inside the fabric industry, as chemical filters, and as fiber-reinforcement composites, because of their comparable homes to engineered fibers, being every other alternative for bio composites and polymer composites. Properties of Fiber Reinforced Concrete:Compressive Strength:The presence of fibers might also additionally regulate the failure mode of cylinders; however the fiber impact can be minor at the development of compressive power values (zero to fifteen percentage). Modulus of Elasticity:Modulus of elasticity of FRC will increase slightly with a boom withinside the fibers content material. It became located that for every 1 percentage boom in fiber content material through quantity there may be a boom of three percentage withinside the modulus of elasticity. Flexure:The flexural power became said [2j to be improved through 2.five instances the usage of four percentage fibers. Toughness:For FRC, sturdiness is set 10 to forty instances that of undeniable concrete. Splitting Tensile Strength:The presence of three percentage fiber through quantity became said to boom the splitting tensile power of mortar approximately 2.5 instances that of the unreinforced one. Fatigue Strength:The addition off bers will increase fatigue power of approximately ninety percentages and 70 percentage of the static power at 2 x 106 cycles for non-opposite and complete reversal of loading, respectively. Impact Resistance:The effect power for fibrous concrete is typically five to ten instances that of undeniable concrete relying at the quantity of fiber Corrosion of Steel Fibers:A lO-12 months’ publicity of steel fibrous mortar to out of doors weathering in an commercial surroundings confirmed no unfavorable impact at the power properties. Corrosion became located to be restricted best to fibers virtually uncovered at the surface. Steel fibrous mortar constantly immerse in seawater for 10 years exhibited a fifteen percentage loss in comparison to forty percentage power lower of undeniable mortar. Flexure:The use of fibers in bolstered concrete flexure contributors will increase ductility, tensile power, second ability, and stiffness. The fibers enhance crack manage and keep publish cracking structural integrity of contributors. Torsion:The use of fiber do away with the unexpected failure feature of undeniable concrete beams. It will increase stiffness, torsion power, ductility, rotational ability, and the range of cracks with much less crack width. Shear:Addition of fibers will increase shear ability of bolstered concrete beams as much as a hundred percentage. Addition of randomly allotted fibers will increase shear-friction power, the primary crack power, and final power. Q4) Explain high performance concrete and pumpable concrete A4)High performance concrete There aren't any unified definitions for High Performance Concretes (HPC) and unique Institutions and professionals in concrete generation define it differently. The American Concrete Institute defines High Performance Concrete as "Concrete that meets unique overall performance and uniformity necessities that can't constantly be received through the usage of traditional substances, regular blending technique and common curing practices." With the necessities, we region on concrete production these days in phrases of sturdiness, velocity of production, energy, lengthy workability, maximum concretes these days qualify as High Performance Concretes (HPC). It need to be remembered that HPC isn't always most effective a characteristic of the concrete, however is a machine composed of the trendy technology of substances (OPC, PFA, Alumino silicates/Micro silica and PCE Admixtures), contemporary blend layout practices, use of the trendy generation to region and end it and powerful curing. Only whilst each step of the procedure above is given due diligence, will the ensuing concrete come to be as excessive overall performance concrete. Based at the revel in of the writer and research worldwide, it's far visible and proved that HPC can most effective be made with the nice substances and practices available. General Experience indicates that the composition of HPC differs significantly from regular concretes. High Performance Concrete (HPC) need to have as a minimum one assets like High energy, High sturdiness, Acid Resistance, Self-compaction, Low permeability to water, Chemicals or different competitive media, in comparison to regular concrete, to qualify as HPC. Material generation has advanced concrete these days into an engineered cloth with numerous new materials. The concrete these days is tailor made for unique packages and it includes numerous unique substances like PFA, GGBSF, Micro silica, Meta kaolin, Colloidal Silica and numerous different Binders, Fillers and Pozzolanic substances. The improvement of specifying the concretes as consistent with its overall performance necessities in preference to the materials and substances in concrete has opened innumerable possibilities for manufacturer and person of concrete to layout concrete as consistent with unique necessities. As constantly, sturdiness will be the top attention as maximum systems can't be effortlessly changed or repaired. Depending upon the correct choice of publicity classes, specialised specs for concrete blend designs could want to evolve. The blend designs are becoming exceptionally complicated due to interplay of numerous substances and require understanding in concrete generation. HPC will quickly turn out to be the norm thinking about its unique residences and occasional price renovation strategies. PUMPABLE CONCRETEProtective concrete is the type of concrete that can be pulled through a construction pipe. It is designed in such a way that its impact on the inner wall of the pipe is not too high and it does not clog as it flows through the pipe. It is very important that you have a clear understanding of what happens to the concrete when piping in any concrete pump study. The protective concrete from the pipe flows in the form of a plug separated from the pipe wall by a soft soft cloth containing cement. The attached water is hydraulic connected with a waterproof inter particle to the plug. Below shows the flow of concrete under pressure. The pressure exerted on the flow resistance should not be greater than the average pressure of the pump to maintain continuous plug movement. However, if the concrete is too high at the w / c ratio, the concrete at a certain pressure of the pump is likely to be forcibly drained from that mixture, creating increased flow resistance and possible clogging. Shows such a situation. In other words, solid concrete is unavoidable and high quality concrete w / c is also unavoidable. It is interesting to note that when concrete is exposed, it is said to be good concrete. Q5) Explain roller compacted concrete and self compacting concrete A5)Roller compacted concrete Roller concrete (RCC) or roll crete concrete is a special compound of concrete with the same ingredients as ordinary concrete but in varying proportions, and depending on the incorporation of part of the fly ash of Portland cement. The incorporation of the fly ash of Portland Cement is an important factor in the construction of the RCC dam because the heat generated by fly ash hydration is much lower than the heat generated by Portland Cement hydration. This in turn lowers the heat load in the dam and reduces the potential for hot cracks to occur. RCC is a mixture of cement / ash of fly, water, sand, composite and common additives, but contains very little water. The resulting mixture will dry out and actually will not fall off. The RCC is positioned in the same way as the paving; the equipment is delivered by dump trucks or conveyors, which are distributed by small tractors or specially designed asphalt pumping stones, and then assembled with vibrating rollers. In the construction of the dam, roller-coated concrete began to develop for the first time with the construction of the Alpe Gera Dam near Sondrio in Northern Italy between 1961 and 1964. The concrete was laid in the same way but not folded. The RCC was adopted in engineering journals in the 1970s as a flexible material suitable for, among other things, the construction of dams. Originally and generally, the RCC was used for back filling, lower foundation and concrete construction, but it is increasingly used in the construction of gravitational dams because low cement content and the use of fly ash produce less heat during curing than conventional concrete laying. Joint roller concrete has many time and cost advantages over conventional concrete dams; this includes high concrete installation costs, low material costs and low costs associated with post-work cooling and formwork. SELF COMPACTING CONCRETESelf-compacting concrete (SCC) is a flowing concrete that doesn't require vibration and, indeed, have to now no longer be vibrated. It makes use of super plasticisers and stabilisers to seriously growth the benefit and price of glide. It achieves compaction into each a part of the mildew or formwork genuinely by using its personal weight with none segregation of the coarse aggregate. The consistence of the concrete is designated and measured as a glide price as opposed to the everyday stoop test. SCC offers:Health and protection benefits (as no vibration is needed). Faster creation times. Increased workability and simplicity of glide round heavy reinforcement. Excellent sturdiness. Advantages of SCC:No vibration is needed in the course of the position into forms. Placement of concrete easier. Reduces the concreting time. Increased sturdiness of structure. High Strength Material used in SCC:The powdered substances that may be delivered are fly ash, silica fume, lime stone powder, glass filler and quartzite filler.Tests for SCC:Following are numerous technique for checking out the houses of sparkling concrete:Slump glide test T50 stoop glide test J ring test V Funnel test V funnel at T5 minute L container test U container test Fill container test GTM display balance test Orimet test

Properties of SCC: Strength: Strength of concrete are of the subsequent types:Compressive strength Tensile strength Flexural strength Shear strength Compressive Strength The dice specimens of concrete of the preferred percentage are solid in metallic or solid iron molds, typically 6-inch dice. The general cylinder specimen of concrete is 6 inch in diameter and 12 inches in peak and solid in a mould commonly fabricated from solid iron; Standard cubes and cylinders are examined at prescribed ages, commonly, 28 days, with extra exams frequently made at 1, three, and seven days. The specimens are examined for crushing electricity below a checking out machine. The dice exams supply an awful lot more values of crushing electricity, typically 20 to 30 % extra than the ones given via way of means of cylinders. Effect of age on concrete strength:Concrete attains electricity with time. Ordinary cement concrete profits above 70 to 75% of its very last electricity inside 28 days and approximately ninety to 95 % withinside the path of 1 year. It is frequently perfect to test the suitability of a concrete lengthy earlier than the effects of the 28-day check are available. When no particular records at the substances utilized in making concrete are available, the 28-day electricity can be assumed to be 1.5 instances of the 7 days’ electricity. Tests have proven that for concrete made with regular Portland cement the ratio of the 28 days to 7 days’ electricity commonly lies among 1.three to 1.7, and the bulk of the effects fall above 1.5. 2. Tensile strengthConcrete could be very susceptible in tension. The tensile electricity of regular concrete levels from approximately 7 to 10 percentage of the compressive electricity. 3. Flexural strengthThe flexural electricity of undeniable concrete is nearly fully established upon the tensile electricity. However, experiments display that the modulus of rupture is substantially more than the electricity in tension. 4. Shear strengthIt is the actual figuring out issue withinside the compressive electricity of brief columns. The common electricity of concrete in direct shear varies from approximately 1/2 of of the compressive electricity for wealthy combinations to approximately 0.8 of the compressive electricity for lean combinations. Workability:The electricity of concrete of a given blend percentage could be very significantly laid low with the diploma of its compaction. It is consequently essential that the consistency of the combination be such that the concrete may be transported, positioned and completed sufficiently effortlessly and with out segregation. A concrete pleasant those situations is stated to be workable. Elastic Properties:Concrete isn't always flawlessly elastic for any variety of loading, an considerable everlasting placing taking location for even low loads. The deformation isn't always proportional to the strain at any degree of loading. The elastic residences of concrete range with the richness of the aggregate and with the depth of the strain. They additionally range with the age of concrete. Durability:Durability is the assets of concrete to face up to the circumstance for which it's been designed, without deterioration over a length of years. Lack of sturdiness may be resulting from outside sellers bobbing up from the surroundings or via way of means of inner sellers in the concrete. Application of SCC:Construction of Bridges, buildings, tunnels. Precast Concrete Members Casting of slab and slender wall Typical Mix:A easy device has been designed for self compacting concrete (SCC) blend layout with 29% of coarse aggregate, substitute of cement with Meta kaolin and sophistication F fly ash, combos of each and managed SCC blend with 0.36 water/cement ratio(via way of means of weight) and 388 liter/m3 of cement paste volume.Q6) Explain significance of concrete and permeability and durability of concrete A6)SIGNIFICANCE Durability is the capacity to remaining a long term without massive deterioration. A long lasting cloth allows the surroundings with the aid of using keeping sources and lowering wastes and the environmental affect of restore and substitute. The manufacturing of substitute constructing substances depletes herbal sources and may produce air and water pollution. Concrete resists weathering action, chemical attack, and abrasion even as retaining its favored engineering houses. Different concretes require extraordinary levels of sturdiness relying at the publicity surroundings and the houses favored. Concrete ingredients, their proportioning, interactions among them, setting and curing practices, and the provider surroundings decide the remaining sturdiness and lifestyles of the concrete. The layout provider lifestyles of maximum homes regularly 30 years, despite the fact that homes regularly remaining 50 to one hundred years or longer. Because in their sturdiness, maximum concrete and masonry homes are demolished because of useful obsolescence in place of deterioration. However, a concrete shell or shape may be repurposed if a constructing use or characteristic adjustments or whilst a constructing indoors is renovated. Concrete, as a structural cloth and because the constructing outside skin, has the capacity to face up to nature’s ordinary deteriorating mechanisms in addition to herbal disasters. Durability of concrete can be described because the capacity of concrete to withstand weathering action, chemical attack, and abrasion even as retaining its favored engineering houses. Different concretes require extraordinary levels of sturdiness relying at the publicity surroundings and houses favored. For example, concrete uncovered to tidal seawater could have extraordinary necessities than an indoor concrete floor. PERMEABILITY AND DURABILITYDefinition: the capacity of a given concrete to allow drinks or gases to by skip through.- ACI Concrete Terminology Permeability is a degree of the quantity of water, air, and different materials which could input the concrete matrix. Concrete consists of pores which could permit those materials to go into or depart. Permeability of concrete may be a number one motive for concrete deterioration because of reinforcing metal corrosion and different deterioration mechanisms. On a macro scale, permeability additionally refers to “porous” slabs used to empty pavements, sidewalks, and parking regions of water, putting off the want for drainage slope, systems, and piping. This technology—every now and then called “no-fines concrete”—is gaining reputation once more with the preference to lessen floor run-off from pavements, sidewalks, and parking regions. Permeability of cement mortar or concrete is of unique importance in systems which might be meant to hold water or which come into touch with water. Besides useful considerations, permeability is likewise in detail associated with the sturdiness of concrete, mainly its resistance, towards revolutionary deterioration below publicity to extreme climate, and leaching because of extended seepage of water, specially whilst it consists of competitive gases or minerals in solution. The willpower of the permeability traits of mortar and concrete, therefore, assumes widespread importance.

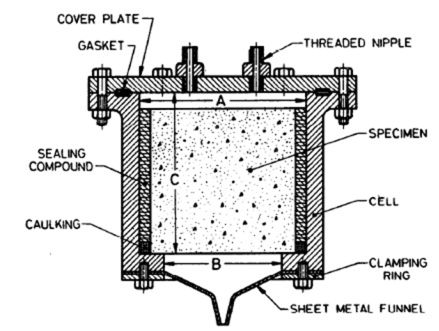

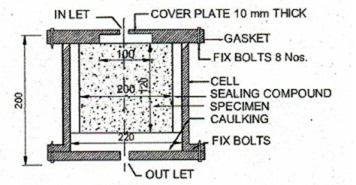

Fig no 1Concrete permeability apparatusThe permeability mobileular shall encompass a steel cylinder for containing the specimen. A rubber or neoprene O-ring or different appropriate gasket, seated in matching grooves will be used among the mobileular and the quilt plate to render the joint water-tight.

Fig no 2Water Reservoir in Permeability ApparatusA appropriate reservoir may also encompass a duration of steel pipe, 50 to a hundred mm in diameter and approximately 500 mm long. The reservoir will be equipped with a graduated facet arm gauge-glass, and the vital fittings and valves for admitting water and compressed air and for draining, bleeding and connection to the permeability mobileular. Procedure:Preparation of Test SpecimenTest specimen of 2 hundred mm diameter and a hundred and twenty mm thich will be used. After 24 hrs of casting of specimen, crucial round place of a hundred mm diameter will be roughened with a twine brush at the facet on which the water stress is to be carried out. The unroughened a part of the facet of the check specimen that's subjected to water stress is to be sealed with coats of cement water paste (W/C = 0.4). Test ProcedureAfter 28 days curing, check specimen is equipped right into a check equipment in which the water stress acts on the specified face and final faces may be observed. At first, a stress of one Bar is carried out for forty eight hours, then three Bar for twenty-four hours and seven Bar for twenty-four hours. After the check, the specimen is break up withinside the center with the aid of using the compression carried out on spherical metal bars mendacity on contrary sides, above and below. The facet after the check specimen uncovered to the water stress ought to face downwards. Observation:The finest water penetration depth, is taken because the common cost of the finest penetration depths on 3 check specimen. Q7) Explain chemical attack and sulphate attack A7)CHEMICAL ATTACKIt depends on the Chemistry and on the Concrete.Indian cement and its ingredients, cement, sand, metal and so on have been damaged beyond all of India's corruption, so the chemical, “Water” (H2O) when combined with air may be sufficient over time. The main causes of chemical attack on concrete include chloride ion infiltration, sulphate attack and carbonation, but technological advances in cementitious coating technology have allowed the use of life-sustaining solutions ” SULPHATE ATTACKCement is composed of two minerals: tri-calcium silicate (C3S), and di-calcium silicate (C2S). In addition to hydration, the main reaction products are calcium silicate gel (C-SH) and calcium hydroxide Ca (OH) 2, labeled as CH in chemistry notation. Moisture is required in this reaction which can cause serious damage to the construction of both the walls and the walls of buildings in buildings. Sulfate attacks occur on the lower slabs. This problem usually affects buildings from the 1950s to the 1960s but can also affect previous buildings where the concrete floor slab is installed. It occurs when the filler material under the slide contains sulphates and this is considered to be a solution with soil moisture entering the concrete that forms the slab on the floor. Attacks can occur from MgSO4 salts, NaSO4 salts, and other salts containing SO3-ions. The interaction of Ca2 + ions with SO4 present in the solution will produce CaSO4 or gypsum. The effect of gypsum on C-S-H gel, which is the main component of reinforced cement, is an irreversible topic. Some substances present in cement, such as tri-calcium aluminate, also interact with sulphate ions. This reaction is well established in the literature. Q8) Explain attack by seawater and acid attack on concrete A8)ATTACK BY SEAWATER Seawater contains sulfate and therefore attacks concrete in the same way as sulfate attack. The deterioration of concrete in seawater is usually not a sign of increase as it is found in concrete exposed to sulphate attacks. Calcium hydroxide and calcium sulphate are highly soluble in seawater, and this will increase leaching action. In the case of reinforced concrete the absorption of salt causes corrosion corrosion. The accumulation of metal corrosion product causes the cracking of the surrounding concrete. So that touch of seawater is much harder on reinforcing concrete than bare concrete. A step to improve the strength of concrete in seawater1) the use of pozzolona or slag cement is beneficial under these circumstances.2) Slag, bat, tin tin, soft limestone, or other porous or weak aggregate will not be used.3) In excess of what may be given to precast members, plastering should be avoided.4) Adequate coverage of about 75mm will be provided.5) Care should be taken to prevent hardening from exposing the salt air during suspension of storage and use. It can be achieved by treating the fortified area by washing the cement or in a proper manner.ACID ATTACK Acid attack is the dissolution and leaching of acid-prone elements, particularly calcium hydroxide, from the cement paste of hardened concrete. This movement outcomes in an boom in capillary porosity, lack of cohesiveness and subsequently lack of power. In said instances, acid assault can be observed with the aid of using crack formation and subsequently disintegration, in particular whilst the shape is subjected at one facet to water pressure. Unlike sulfate assault (see beneathneath), the goods fashioned from acid assault aren't expansive, and leaching will handiest arise in systems which are tremendously permeable. In excessive overall performance concrete structures containing cement pastes with a low content material of calcium hydroxide, acid assault is relative gradual and can contain handiest the finely divided calcium hydroxide crystals included withinside the interstices of the calcium silicate hydrates, C-S-H. The micrographs received from PFM analysis, supplemented with SEM–EDS studies, monitor that handiest the top, floor part of the concrete has been attacked with the aid of using acidic answer. The relaxation of the concrete suggests no shape of degradation. In the attacked zone, there's clean proof of leaching of the cement paste matrix, main to accelerated capillary porosity and lack of brotherly love of the matrix. Locally, there's lack of bonding of the cement paste to aggregate, however at the whole, those elements have now no longer adversely affected the microstructure and nice of the concrete. In this instance, long-time period sturdiness of the concrete isn't always probably to be compromised.

Fig no 3Acid Attack on Concrete blockAcid assault of concrete takes 3 forms. First, hydration merchandise react with the acid to shape dissolved ions, main to lack of strong material—acidolysis. Second, withinside the case of a few acids, insoluble salts shape, a number of which precipitate to purpose growth and cracking. Finally, a few acids supply complexes with calcium, aluminium, iron and silicate ions which produce an awful lot better concentrations of those ions in answer than could in any other case be the case, once more main to dissolution. This can probably arise at pH situations beneathneath which cement could usually be tremendously stable (complexolysis). Depending at the acid present, extra than this sort of deterioration mechanisms can be powerful. Where acidolysis is the main mechanism, an acid answer penetrating the pores of concrete will begin to purpose a number of the elements to dissolve. Calcium is generally the primary cation to be dissolved, considering that portlandite will become soluble beneathneath tremendously excessive pH values. AFm and AFt stages commonly dissolve at barely decrease pH values, even though strong aluminium and iron hydroxides are precipitated, which persist till the answer is tremendously acidic. Exposure to acidic answer additionally reasons lack of calcium—decalcification—of C-S-H gel, leaving tremendously vulnerable silica gel behind. The importance of calcium on this shape of degradation approach that adjusting the composition of the cement matrix of concrete to attain a decrease calcium content material will probably impart extra resistance. Thus, pozzolanic substances can be powerful in improving resistance to this form of acid assault, considering that their aggregate with PC will produce such an adjustment. However, decreased quotes of mass shipping and more desirable power done thru the usage of pozzolanic substances also are probably to be motives for progressed resistance. Q9) Explain chloride attack A9)CHLORIDE ATTACK Chloride Attack Chloride attack is one of the most important factors when working with concrete strength. It mainly causes corrosion corrosion. Statistics have shown that more than 40% of structural failures are due to metal corrosion. Concrete and the penetration layer with a strong alkaline Ca (OH) 2 (pH approximately 13) prevents metal corrosion by forming a thin film to protect the iron oxide on the surface of the metal. This protection is known as inaction. If concrete can penetrate in such a way that the dissolved chloride enters until it hardens and water and oxygen are also present, then corrosion of the metal will occur. This layer can also be lost due to carbonation. Chloride enters the concrete from cement, water, and is sometimes mixed from tips. This can come in increments from nature when the concrete is filled. The Bureau of Indian Standard specified the high chloride content in cement as 0.1%. The amount of chloride needed to start corrosion depends on the pH value of the pore water in the concrete. A pH value below 11.5 corrosion is possible without the presence of chloride. Q10) Explain carbonation of concrete and its determination A10)CARBONATION OF CONCRETE AND ITS DETERMINATIONCarbonation of concrete is associated with corrosion of steel reinforcement and shrinkage. However, it also increases both the compression strength and the strength of the concrete, so not all of its effects on concrete are bad. Carbonation is the result of the decomposition of CO2 in pore fluid in concrete and this reacts with calcium from calcium hydroxide and calcium silicate hydrate to form calcite (CaCO3). Aragonite can form in hot climates. Within a few hours, or a day or two in total, the new concrete will be processed by CO2 in the air. Gradually, the process penetrates deeper into the concrete at a rate equal to the square root of time. After a year or more it is likely to reach a depth of about 1 mm with dense low-penetration concrete made of low water / cement, or up to 5 mm or more of high-density and permitted concrete using high water / cement scale. Carbonation determinationThe affected depth from the concrete surface can be easily indicated by the use of a phenolphthalein indicator solution. This is available from chemical suppliers. Phenolphthalein is a white or pale yellow with a crystal. Use as a solvent dissolve in a suitable solution such as isopropyl alcohol (isopropanol) by 1%. The indicator has not changed color near the upper and lower extremities, suggesting that these regions near the surface be carbonated at a depth of at least 4 mm from the top to the top and 6 mm from the bottom. When the index turns purple - in the middle of the slide - the pH of the pore fluid anchor remains high (above 8.6, about 10). Whether you are pasting the cement here is not completely illuminated, despite the strong purple color; a complete test will require very little testing. The index was not applied to the concrete to the right of this image so the concrete here retains its original color. The depth of carbonation is about the same as the square root of time. For example, if the depth of carbon is 1mm in one-year-old concrete, it will be about 3mm after 9, 5mm after 25 years and 10mm after 100 years.

Sr.no. | Method | Units | Typical mix | |

Minimum | Maximum | |||

1 | Slump cone by Abrams cone | mm | 650 | 800 |

2 | T50slumpflow | sec | 2 | 5 |

3 | J ring | mm | 0 | 10 |

4 | V funnel | sec | 8 | 12 |

5 | VfunnelatT5minute | sec | 0 | 3 |

6 | L box | (h2/h1) | 0.8 | 1.0 |

7 | U box | (h2-h1) mm | 0 | 30 |

8 | Fill box | % | 90 | 100 |

9 | GTM scree nst ability test | % | 0 | 15 |

10 | Orimet | sec | 0 | 5 |

|

|

|

0 matching results found