Unit 6:

Manufacturing Processes

Questions

Question 1) Explain advantages disadvantages of different kind of casting?

Answer 1)

Sand Casting | ||

Advantages | Disadvantages | Recommended Application |

Least Expensive in small quantities (less than 100) | Dimensional accuracy inferior to other processes, requires larger tolerances | Use when strength/weight ratio permits |

Permanent and Semi-permanent Mold Casting | ||

Less expensive than Investment or Die Castings | Only non-ferrous metals may be cast by this process | Use when process recommended for parts subjected to hydrostatic pressure |

Plaster Cast | ||

Smooth "As Cast" finish (25 RMS) | More costly than Sand or Permanent Mold-Casting | Use when parts require smooth "As Cast" surface finish and closer tolerances than possible with Sand or Permanent Mold Processes |

Investment Cast | ||

Close dimensional tolerance | Costs are higher than Sand, Permanent Mold or Plaster process Castings | Use when Complexity precludes use of Sand or Permanent Mold Castings |

Die Casting | ||

Good dimensional tolerances are possible | Economical only in very large quantities due to high tool cost | Use when quantity of parts justifies the high tooling cost |

Question 2) what is sand casting?

Answer 2)

Sand Casting

Sand casting typically relies on silica-based materials, such as synthetic or naturally-bonded sand. Casting sand generally consists of finely ground, spherical grains that can be tightly packed together into a smooth molding surface. The casting is designed to reduce the potential for tearing, cracking, or other flaws by allowing a moderate degree of flexibility and shrinkage during the cooling phase of the process. The sand can also be strengthened with the addition of clay, which helps the particles bond more closely. Automotive products such as engine blocks are manufactured through sand casting.

Sand casting involves several steps, including patternmaking, molding, melting and pouring, and cleaning. The pattern is the form around which the sand is packed, usually in two parts, the cope and the drag. After the sand is compacted enough to replicate the pattern, the cope is removed and the pattern extracted. Then, any additional inserts called core boxes are installed and the cope is replaced. After the metal has been poured and solidified, the casting is removed, trimmed of the risers and gates that were used in the pouring process, and cleaned of any adhered sand and scale.

Sand casting's main advantages as a casting process include:

- Relatively inexpensive production costs, especially in low-volume runs.

- The ability to fabricate large components.

- A capacity for casting both ferrous and non-ferrous materials.

- A low cost for post-casting tooling.

Despite its benefits, sand casting yields a lower degree of accuracy than do alternate methods and it can be difficult to sand cast components with a predetermined size and weight specifications. Furthermore, this process has a tendency to yield products with a comparatively rough surface finish.

Question 3)Explain investment casting?

Answer 3)

Investment Casting

Investment, or lost-wax, casting uses a disposable wax pattern for each cast part. The wax is injected directly into a mold, removed, then coated with refractory material and a binding agent, usually in several stages to build up a thick shell. Multiple patterns are assembled onto common sprues. Once the shells have hardened the patterns are inverted and heated in ovens to remove the wax. Molten metal is then poured into the remaining shells where it hardens into the shape of the wax patterns. The refractory shell is broken away to reveal the completed casting. Investment casting is often used to manufacture parts for the automotive, power generation, and aerospace industries, such as turbine blades. Some of the central advantages and disadvantages of investment casting include:

- A high degree of accuracy and precise dimensional results.

- The ability to create thin-walled parts with complex geometries.

- The capacity for casting both ferrous and non-ferrous materials.

- Relatively high-quality surface finish and detail in final components.

Although it is highly precise, investment casting is usually more expensive than other comparable casting techniques and is typically only cost-efficient when sand or plaster castings cannot be used. However, the expense can sometimes be compensated for with reduced machining and tooling costs due to investment castings’ quality surface results.

Question 4) what is plaster casting?

Answer 4)

Plaster Casting

Plaster casting is similar to the sand casting process, using a mixture of gypsum, strengthening compound, and water in place of the sand. The plaster pattern is typically coated with an anti-adhesive compound to prevent it from becoming stuck against the mold, and the plaster is capable of filling in any gaps around the mold. Once the plaster material has been used to cast the part, it usually cracks or forms defects, requiring it to be replaced with fresh material. The advantages offered by plaster casting include:

- A very smooth surface finish.

- The ability to cast complex shapes with thin walls.

- The capacity for forming large parts with less expense than other processes, such as investment casting.

- A higher degree of dimensional accuracy than that of sand casting.

This process tends to be more expensive than most sand casting operations and may require frequent replacements of the plaster molding material. It is usually more effective and cost-efficient when the quality of the surface finish is an important requirement. Its application is generally limited to casting aluminium and copper-based alloys.

Question 5) what is die casting?

Answer 5)

Die Casting (Metal Casting Process)

Die casting is a method of molding materials under high pressure and usually involves non-ferrous metals and alloys, such as zinc, tin, copper, and aluminium. The reusable mold is coated with a lubricant to help regulate the die’s temperature and to assist with component ejection. Molten metal is then injected into the die under high pressure, which remains continuous until the workpiece solidifies. This pressurized insertion is rapid, preventing any segment of the material from hardening before being cast. After the process is completed, the component is taken out of the die and any scrap material is removed. A few of the major advantages provided by die casting include:

- Close size and shape tolerances.

- High component dimensional consistency and uniform design.

- A reduced need for post-casting machining.

Despite its advantages, die casting as a metal casting process has relatively high tool costs, making it more cost-efficient in high-volume product runs. It can also be difficult to ensure the mechanical properties of a die-cast component, meaning these products usually do not function as structural parts. As the molds are typically two-piece, die casting is limited to products that can be removed from the mold without destroying the mold, as is done in other casting processes.

Question 6) what is centrifugal casting?

Answer 6)

Centrifugal Casting

Centrifugal casting is used to produce long, cylindrical parts such as cast iron pipe by relying on the g-forces developed in a spinning mold. Molten metal introduced into the mold is flung against the interior surface of the mold, producing a casting that can be free of voids. Originally invented as the de Levied process using water-cooled molds, the method is applied to symmetrical parts such as soil pipe and large gun barrels and has the advantage of producing parts using a minimal number of risers. For asymmetric parts that cannot be spun around their own axes, a variant of centrifugal casting, called pressure casting, arranges several parts around a common sprue and spins the molds around this axis. A similar idea is applied to the casting of very large gear rings, etc. Depending on the material being cast, metal or sand molds may be used.

Question 7) what is permanent mold casting?

Answer 7)

Permanent Mold Casting

Permanent mold casting shares similarities with die casting and centrifugal casting, notably the use of reusable molds. These can be made of steel, graphite, etc. and are generally used to cast materials such as lead, zinc, aluminium and magnesium alloys, certain bronzes, and cast iron. It is a low-pressure process with pouring usually done by hand using multiple molds on a turntable. As the molds rotate through the various stations they are successively coated, closed, filled, opened, and emptied. One such method is known as slush casting, where the mold is filled but emptied before the metal fully hardens. Molten metal is dumped from the casting to produce a hollow, cast shell. A similar idea is used in the molding of hollow chocolate products such as Easter bunnies. The use of metal molds induces faster heat transfer through the mold, allowing the shell to harden while the core remains liquid.

Question 8) what are the factors that needs to considered in casting?

Answer 8)

There are numerous factors that need to be considered to ensure proper size, shape and integrity of the final component. Some of these factors include:

- Type of material: each metal and casting material retains specific characteristics (hardness, melting point, density, etc.) that will affect the casting process.

- Cooling rate: This factor depends largely on the type of material from which you craft the mold. Proper cooling is necessary to minimize gas porosity and other negative properties that can result from a fast cooling rate.

- Shrinkage: As castings cool, they shrink. To ensure proper component size and integrity, you can utilize risers to feed additional molten metal into the cavity. An oversized mold may also be useful in some applications.

Question 9) explains casting applications?

Answer 9) Today, castings are used in virtually all walks of life. The following is a partial list of applications, with transport sector and heavy equipment taking up over 50% of castings produced:

- Transport: automobile, aerospace, railways and shipping

- Heavy equipment: construction, farming and mining

- Machine tools: machining, casting, plastics moulding, forging, extrusion and forming

- Plant machinery: chemical, petroleum, paper, sugar, textile, steel and thermal plants

- Defense: vehicles, artillery, munitions, storage and supporting equipment

- Electrical machines: motors, generators, pumps and compressors

- Municipal castings: pipes, joints, valves and fittings

- Household: appliances, kitchen and gardening equipment, furniture and fittings

- Art objects: sculptures, idols, furniture, lamp stands and decorative items.

Question 10) explain types of metal removal process?

Answer 10) Types of material removal processes

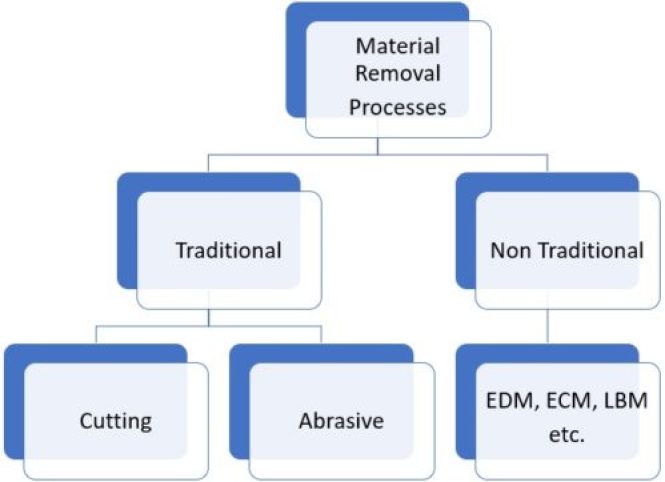

Material removal processes are mainly divided into two types traditional and non-traditional.

Traditional machining processes are the processes which are used from the ancient times till today. They are used for almost all general kind of product manufacturing. Examples of these processes are turning, drilling, lapping etc.

Non-traditional machining processes are the processes which are not in general use and are only used for very high-quality engineering works. Examples of non-traditional material removal processes are Electro Chemical Machining (ECM), Electric Discharge Machining (EDM) etc.

With the help of below diagram you can further understand the types of material removal processes in a better way.

Unit 6:

Manufacturing Processes

Questions

Question 1) Explain advantages disadvantages of different kind of casting?

Answer 1)

Sand Casting | ||

Advantages | Disadvantages | Recommended Application |

Least Expensive in small quantities (less than 100) | Dimensional accuracy inferior to other processes, requires larger tolerances | Use when strength/weight ratio permits |

Permanent and Semi-permanent Mold Casting | ||

Less expensive than Investment or Die Castings | Only non-ferrous metals may be cast by this process | Use when process recommended for parts subjected to hydrostatic pressure |

Plaster Cast | ||

Smooth "As Cast" finish (25 RMS) | More costly than Sand or Permanent Mold-Casting | Use when parts require smooth "As Cast" surface finish and closer tolerances than possible with Sand or Permanent Mold Processes |

Investment Cast | ||

Close dimensional tolerance | Costs are higher than Sand, Permanent Mold or Plaster process Castings | Use when Complexity precludes use of Sand or Permanent Mold Castings |

Die Casting | ||

Good dimensional tolerances are possible | Economical only in very large quantities due to high tool cost | Use when quantity of parts justifies the high tooling cost |

Question 2) what is sand casting?

Answer 2)

Sand Casting

Sand casting typically relies on silica-based materials, such as synthetic or naturally-bonded sand. Casting sand generally consists of finely ground, spherical grains that can be tightly packed together into a smooth molding surface. The casting is designed to reduce the potential for tearing, cracking, or other flaws by allowing a moderate degree of flexibility and shrinkage during the cooling phase of the process. The sand can also be strengthened with the addition of clay, which helps the particles bond more closely. Automotive products such as engine blocks are manufactured through sand casting.

Sand casting involves several steps, including patternmaking, molding, melting and pouring, and cleaning. The pattern is the form around which the sand is packed, usually in two parts, the cope and the drag. After the sand is compacted enough to replicate the pattern, the cope is removed and the pattern extracted. Then, any additional inserts called core boxes are installed and the cope is replaced. After the metal has been poured and solidified, the casting is removed, trimmed of the risers and gates that were used in the pouring process, and cleaned of any adhered sand and scale.

Sand casting's main advantages as a casting process include:

- Relatively inexpensive production costs, especially in low-volume runs.

- The ability to fabricate large components.

- A capacity for casting both ferrous and non-ferrous materials.

- A low cost for post-casting tooling.

Despite its benefits, sand casting yields a lower degree of accuracy than do alternate methods and it can be difficult to sand cast components with a predetermined size and weight specifications. Furthermore, this process has a tendency to yield products with a comparatively rough surface finish.

Question 3)Explain investment casting?

Answer 3)

Investment Casting

Investment, or lost-wax, casting uses a disposable wax pattern for each cast part. The wax is injected directly into a mold, removed, then coated with refractory material and a binding agent, usually in several stages to build up a thick shell. Multiple patterns are assembled onto common sprues. Once the shells have hardened the patterns are inverted and heated in ovens to remove the wax. Molten metal is then poured into the remaining shells where it hardens into the shape of the wax patterns. The refractory shell is broken away to reveal the completed casting. Investment casting is often used to manufacture parts for the automotive, power generation, and aerospace industries, such as turbine blades. Some of the central advantages and disadvantages of investment casting include:

- A high degree of accuracy and precise dimensional results.

- The ability to create thin-walled parts with complex geometries.

- The capacity for casting both ferrous and non-ferrous materials.

- Relatively high-quality surface finish and detail in final components.

Although it is highly precise, investment casting is usually more expensive than other comparable casting techniques and is typically only cost-efficient when sand or plaster castings cannot be used. However, the expense can sometimes be compensated for with reduced machining and tooling costs due to investment castings’ quality surface results.

Question 4) what is plaster casting?

Answer 4)

Plaster Casting

Plaster casting is similar to the sand casting process, using a mixture of gypsum, strengthening compound, and water in place of the sand. The plaster pattern is typically coated with an anti-adhesive compound to prevent it from becoming stuck against the mold, and the plaster is capable of filling in any gaps around the mold. Once the plaster material has been used to cast the part, it usually cracks or forms defects, requiring it to be replaced with fresh material. The advantages offered by plaster casting include:

- A very smooth surface finish.

- The ability to cast complex shapes with thin walls.

- The capacity for forming large parts with less expense than other processes, such as investment casting.

- A higher degree of dimensional accuracy than that of sand casting.

This process tends to be more expensive than most sand casting operations and may require frequent replacements of the plaster molding material. It is usually more effective and cost-efficient when the quality of the surface finish is an important requirement. Its application is generally limited to casting aluminium and copper-based alloys.

Question 5) what is die casting?

Answer 5)

Die Casting (Metal Casting Process)

Die casting is a method of molding materials under high pressure and usually involves non-ferrous metals and alloys, such as zinc, tin, copper, and aluminium. The reusable mold is coated with a lubricant to help regulate the die’s temperature and to assist with component ejection. Molten metal is then injected into the die under high pressure, which remains continuous until the workpiece solidifies. This pressurized insertion is rapid, preventing any segment of the material from hardening before being cast. After the process is completed, the component is taken out of the die and any scrap material is removed. A few of the major advantages provided by die casting include:

- Close size and shape tolerances.

- High component dimensional consistency and uniform design.

- A reduced need for post-casting machining.

Despite its advantages, die casting as a metal casting process has relatively high tool costs, making it more cost-efficient in high-volume product runs. It can also be difficult to ensure the mechanical properties of a die-cast component, meaning these products usually do not function as structural parts. As the molds are typically two-piece, die casting is limited to products that can be removed from the mold without destroying the mold, as is done in other casting processes.

Question 6) what is centrifugal casting?

Answer 6)

Centrifugal Casting

Centrifugal casting is used to produce long, cylindrical parts such as cast iron pipe by relying on the g-forces developed in a spinning mold. Molten metal introduced into the mold is flung against the interior surface of the mold, producing a casting that can be free of voids. Originally invented as the de Levied process using water-cooled molds, the method is applied to symmetrical parts such as soil pipe and large gun barrels and has the advantage of producing parts using a minimal number of risers. For asymmetric parts that cannot be spun around their own axes, a variant of centrifugal casting, called pressure casting, arranges several parts around a common sprue and spins the molds around this axis. A similar idea is applied to the casting of very large gear rings, etc. Depending on the material being cast, metal or sand molds may be used.

Question 7) what is permanent mold casting?

Answer 7)

Permanent Mold Casting

Permanent mold casting shares similarities with die casting and centrifugal casting, notably the use of reusable molds. These can be made of steel, graphite, etc. and are generally used to cast materials such as lead, zinc, aluminium and magnesium alloys, certain bronzes, and cast iron. It is a low-pressure process with pouring usually done by hand using multiple molds on a turntable. As the molds rotate through the various stations they are successively coated, closed, filled, opened, and emptied. One such method is known as slush casting, where the mold is filled but emptied before the metal fully hardens. Molten metal is dumped from the casting to produce a hollow, cast shell. A similar idea is used in the molding of hollow chocolate products such as Easter bunnies. The use of metal molds induces faster heat transfer through the mold, allowing the shell to harden while the core remains liquid.

Question 8) what are the factors that needs to considered in casting?

Answer 8)

There are numerous factors that need to be considered to ensure proper size, shape and integrity of the final component. Some of these factors include:

- Type of material: each metal and casting material retains specific characteristics (hardness, melting point, density, etc.) that will affect the casting process.

- Cooling rate: This factor depends largely on the type of material from which you craft the mold. Proper cooling is necessary to minimize gas porosity and other negative properties that can result from a fast cooling rate.

- Shrinkage: As castings cool, they shrink. To ensure proper component size and integrity, you can utilize risers to feed additional molten metal into the cavity. An oversized mold may also be useful in some applications.

Question 9) explains casting applications?

Answer 9) Today, castings are used in virtually all walks of life. The following is a partial list of applications, with transport sector and heavy equipment taking up over 50% of castings produced:

- Transport: automobile, aerospace, railways and shipping

- Heavy equipment: construction, farming and mining

- Machine tools: machining, casting, plastics moulding, forging, extrusion and forming

- Plant machinery: chemical, petroleum, paper, sugar, textile, steel and thermal plants

- Defense: vehicles, artillery, munitions, storage and supporting equipment

- Electrical machines: motors, generators, pumps and compressors

- Municipal castings: pipes, joints, valves and fittings

- Household: appliances, kitchen and gardening equipment, furniture and fittings

- Art objects: sculptures, idols, furniture, lamp stands and decorative items.

Question 10) explain types of metal removal process?

Answer 10) Types of material removal processes

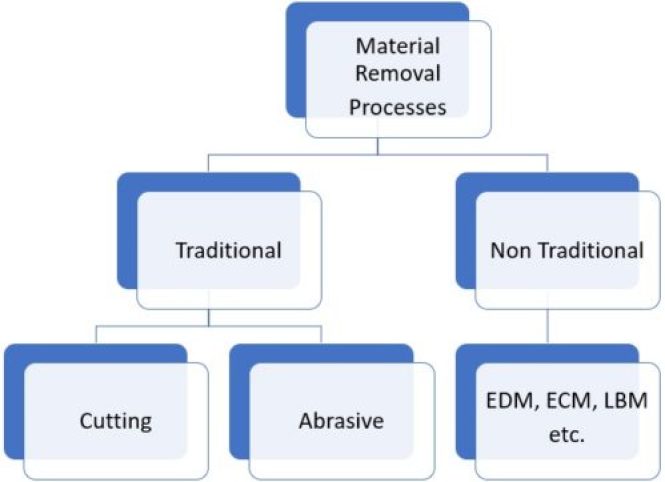

Material removal processes are mainly divided into two types traditional and non-traditional.

Traditional machining processes are the processes which are used from the ancient times till today. They are used for almost all general kind of product manufacturing. Examples of these processes are turning, drilling, lapping etc.

Non-traditional machining processes are the processes which are not in general use and are only used for very high-quality engineering works. Examples of non-traditional material removal processes are Electro Chemical Machining (ECM), Electric Discharge Machining (EDM) etc.

With the help of below diagram you can further understand the types of material removal processes in a better way.