Unit - 2

Organometallic Compounds-II

Q1) Describe in brief the characteristics of Metal-Alkyl Complexes.

A1)

Metal-Alkyl Complexes:

Because of the weak metal-carbon bonds, metal-alkyl complexes were once assumed to be unstable, making them difficult to produce. Actually, the issue is with their kinetic stability. Metal alkyls typically proceed through low-activation-barrier breakdown processes. Simple alkyls are sigma donors, meaning they can donate one or two electrons to the metal.

Properties

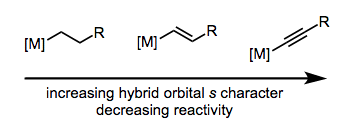

A positive, charged metal and a negative, charged carbon make up the metal carbon bond (M-C). As illustrated in Figure, as metals' electronegativity increases, their reactivity decreases. To clarify, the reactivity of the alkyl ligand is inversely proportional to the electronegativity of the metal centre.

Sp-hybridized ligands are the least nucleophilic in terms of carbon hybridization. The nucleophilic order of the ligands is illustrated in the figure to the right.

Synthesis

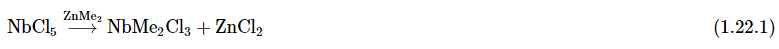

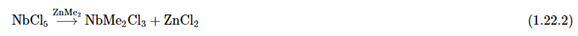

1. Alkyl complexes are commonly attacked by nucleophilic reagents such as R-Li or Pb-(R)4 Stronger nucleophiles can sometimes result in an undesired reduction, hence these nucleophiles vary from strong to weak. Pearson's hard-soft principles describe and elaborate on alkylation interactions. As the alkyl ligand travels from one metal to another, metals with strong leaving groups are more likely to be attacked by nucleophiles.

Nucleophilic attack

2. Electrophilic attack occurs when an anionic metal complex has a strong enough nucleophile to attack alkyl and acyl halides (Figure). The metal must have a readily available lone pair and an open coordination location for this to happen. The electrophile's leaving group receives a negative charge, while the overall charge of the complex increases by one.

Electrophillic attack

3. Another form of synthesis is oxidative addition, which has many processes. M + X-Y -> M-X-Y is an example of oxidative addition in which X-Y is cleaved and a new creation of ligands (-X and -Y) on the metal occurs. The metal's oxidation state is then raised, and the total electron count of the complex is increased by two.

Oxidation Addition

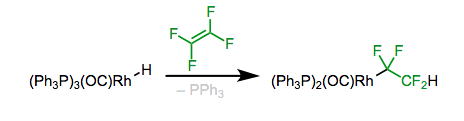

4. Migratory insertion, as shown in Figure, is another way for synthesising alkyl compounds, resulting in an addition across pi bonds. This method can be used to make certain alkyl complexes. Because the perfluoroalkyl compound is stable, insertion of fluoroalkenes is often preferable to removal (take note of the Figure on the right).

.

Q2) Define Important structural features of methyl lithium tetramer.

A2)

Because of the partial negative charge on carbon, methyllithium is both strongly basic and very nucleophilic, making it exceptionally reactive with electron acceptors and proton donors. Both in solution and in the solid state, the compound takes on an oligomere structure. David B. Collum and Brett L. Lucht The simplest organolithium reagent is methyllithium, which has the empirical formula CH 3 Li. We're all aware that high doses of lithium carbonate are used to treat bipolar and manic depression, and that toxicity must be properly monitored with blood testing. Li is purple, C is black, and H is white. We use cookies to help us provide and improve our service, as well as to customise content and advertisements. In both solution and solid state, this s-block organometallic molecule has an oligomeric structure. Final Thoughts The importance of a covalent component in the polar C-Li bond, particularly in the methyllithium tetramer, is highlighted in this study. CtBP231–364 Tetrameric Model The final cryo-EM map of CtBP231–364 revealed extremely distinct secondary structural features (Figure), allowing rigid-body simulations. The following is a list of some of the most common and significant hemoglobin variations ANW-39739. The majority of methyllithium reactions take place below room temperature. CTK5I1135 is a CTK5I1135 is a CT It also produces lithium acetate when it combines with carbon dioxide: MeLi can be used to make transition metal methyl compounds by reacting it with metal halides. This highly reactive molecule is a reagent in organic synthesis and organometallic chemistry, and is always utilized as a solution in ethers. Ar = 3,5tBu 2 C 6 H 3 Ar = 3,5tBu 2 C 6 H 3 Ar = 3,5tBu 2 C 6 H Hemoglobin A is a tetramer made up of two alpha and two beta chains (a 2 b 2). The structure of methyllithium reported a tetramer unit, as did the structure of tetramer units. A number of open structures can also develop from unusual solvation and structural properties, mainly as a result of a lithium's particularly strong polydendate coordination (2-, 3-, or 4-open structures). 1) Butyllithiums are common metalation reagents. The minimum electrostatic energy of a collection of four positive and four negative point charges arranged as two interpenetrating tetrahedra subject only to Coulombic forces is 0.783, which is consistent with the observed Li polydentate to C distance ratio of 0.73 in the structure of methyllithium tetramer. Because lithium chloride does not form a strong combination with methyllithium, it precipitates from diethyl ether. Preparation and reactions with ferrocene... 2021 Elsevier B.V. Or its licensors or contributors Copyright An ab initio computational technique was used to investigate the properties of the methyllithium species Li 4 (CH 3) 3 +, Li 4 (CH 3) 2 +, Li 4 CH 3 +, Li 2 CH 3 +, LiCH 3 +, and Li 2 (CH 3 2). Methyl-lithium has a C-Li distance of 2.31. T-butyllithium, for example, exists as a tetramer with a cubane-like structure. MFCD00008253 is the MDL number. 1.6 M methyllithium sol. The structure of the methyllithium tetramer (CH3Li)4 in the bcc crystal has been theoretically optimized using density functional theory calculations... This highly reactive molecule is a reagent in organic synthesis and organometallic chemistry, and is always utilized as a solution in ethers. Methyllithium-based operations... This reagent is commonly employed for nucleophilic substitutions of epoxides, alkyl halides, and alkyl sulfonates, as well as conjugate additions of methyl anion to unsaturated carbonyl compounds. The role of triethylaluminium in ethene polymerisation (Ziegler - Natta Catalyst). When heated to breakdown, Methyl Methanesulfonate is a stable, colourless, flammable liquid that releases poisonous sulfoxide vapours. Methyl Lithium Tetramer Structure Calculated using a Dimethyl Ether Molecule Solvated and nonsolvated tetramers are the two types of tetramers. In tetrahydrofuran, LDA is a solvated dimer, but in non-polar solvents, it forms temperature-dependent oligomers such as trimers, tetramers, and pentamers. These lithium cluster species are the methyl analogues of the products discovered in experiments when ethyllithium and t-butyllithium are fragmented. Ketones, for example, undergo a two-step reaction to yield tertiary alcohols: Methyllithium converts nonmetal halides to methyl compounds: The Grignard reagents methylmagnesium halides, which are typically similarly efficient and less expensive or easier to synthesise in situ, are more typically used in such reactions. This highly reactive molecule is a reagent in organic synthesis and organometallic chemistry, and is always utilised as a solution in ethers. The larger cluster (tertiary-butylLi)4, on the other hand, is volatile and soluble in alkanes, despite the fact that intercluster interactions are prevented by steric effects.

Q3) State the applications and limitations of Ziegler-Natta Catalyst.

A3)

Applications

The Ziegler-Natta catalyst polymerisation is a useful and adaptable polymerization reaction. This catalyst is employed in the manufacturing of high and low-density polyethylene, among other things.

Thermoplastic polyolefins, polybutylene, crystalline polypropylene, and carbon nanotube nanocomposites are all manufactured.

Limitation of Ziegler-Natta Catalyst

The Ziegler-Natta polymerization method has some drawbacks, as it does not operate with all monomers. Ziegler-Natta polymerisation cannot produce products like poly(vinyl chloride). Another example would be acrylates.

Problem EA13.1: Draw the first intermediate generated during the cationic polymerization start phase of:

a. Ethene

b. Propene

Polyethylene and polypropylene, unlike the other polymers of alkenes we've looked at, are not polymerized via cationic techniques.

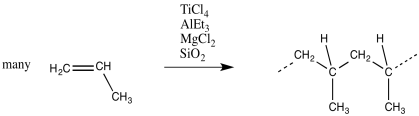

Instead, a method known as "Ziegler-Natta polymerization" is used to enchain these monomers. This technique is named after two chemists, one from Germany and the other from Italy, who are both credited with developing it in the 1950s.

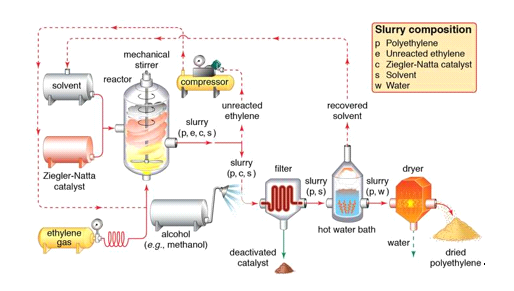

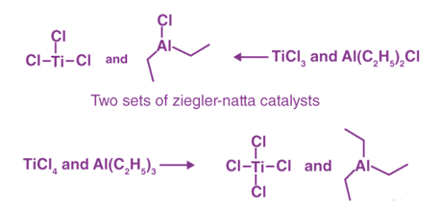

Monomers are treated with a catalyst, such as a combination of titanium chloride (or similar compounds, such as oxovanadium chloride) and triethylaluminum chloride, in Ziegler-Natta polymerization (or trimethylaluminum). Other ingredients, such as magnesium chloride, are frequently added to change the catalyst and improve performance. The mixture generates a heterogeneous catalyst, which is a solid that is insoluble.

Because all of these components react together to create something new, the catalyst is no longer titanium chloride. It's possible that determining exactly what they create is difficult.

Despite the intricate catalyst mixture, we have a basic understanding of the reaction mechanism. This information is derived in part from investigations using model chemicals. Model compounds are less complex than industrial catalysts, yet they share some structural similarities with their more powerful cousins. They share enough similarities to perform polymerization catalysis, though perhaps not as well as the industrial heavyweights.

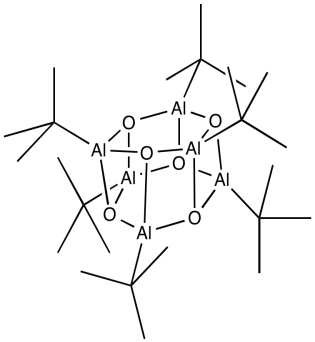

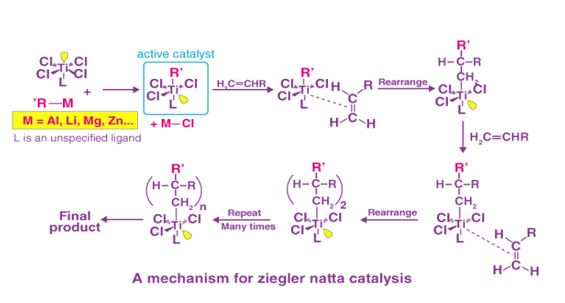

So, what do we believe will happen? It appears that one of the functions of trialkylaluminum is to furnish titanium with an alkyl group. That shouldn't come as a shock. Like ethyllithium or ethylmagnesium bromide, triethylaluminum should be a source of nucleophilic ethyl groups. With halide leaving groups, titanium tetrachloride should be a rather good electrophile. At least one of the chlorides could be substituted with an ethyl ligand.

Ethylation of titanium tetrachloride with triethylaluminum requires a mechanism.

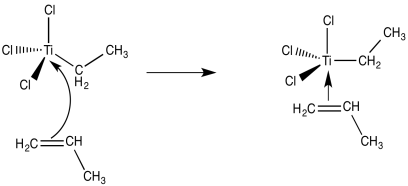

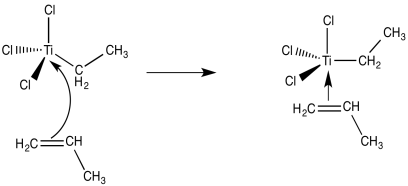

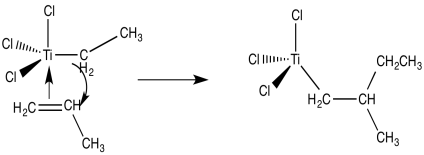

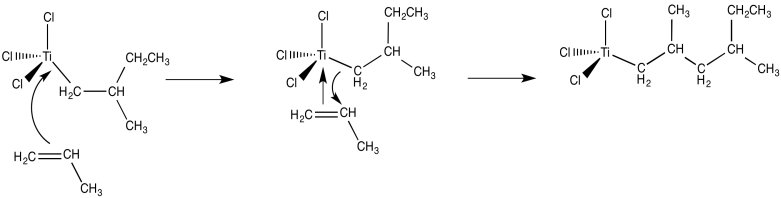

The binding of an alkene ligand to the transition metal could be the next step.

We're now dealing with an organotransition metal complex. Organometallic reaction processes should be considered. A 1,2-insertion of the alkene into the metal-carbon bond, for example, would result in a new metal alkyl.

From there, polymerization of propene can be easily imagined by repeating these basic processes in a sequential order. The propene dimer is formed by bonding an extra alkene followed by the 1,2-insertion of the propene into the metal-carbon bond (with a methyl end group).

- Alkene binding and insertion into metal-carbon bonds are involved in Ziegler-Natta polymerization.

- Let's take a step back and examine the role of the aluminium compound in greater detail. This topic is unrelated to electrophilic addition, although it is relevant to the field of catalysis.

- "Promoters" and "supports" are sometimes used in catalysis to improve catalyst function. They could accomplish it in a variety of ways. They may participate directly in the process, giving additional Lewis acidic or Lewis basic sites, similar to how amino acid residues surrounding an enzyme's active site may aid in catalysis. They may play a more subtle function, altering the catalyst's physical qualities (such as solubility) or even tuning up the catalyst's chemical properties. For instance, the promoter may increase the electron density of the catalyst, making it less electrophilic. That could make the catalyst more stable; it could also make it more selective, reacting more thoughtfully rather than recklessly. It's possible that it extends the catalyst's life.

- Although traditional Ziegler-Natta polymerization uses heterogeneous catalysis, there have been many modifications produced, including model systems for studying the reaction's fundamentals as well as alternative, working homogeneous catalysts. Walter Kaminsky of the University of Hamburg produced an effective version that uses Cp2ZrCl2 as a catalyst and methylalumoxane (MAO) as a promoter. A "zirconocene" is a zirconium species in which the zirconium atom is sandwiched between two cyclopentadienly ligands.

MAO is yet another species with a hazy definition. Trimethylaluminum is treated with a trace of moisture to produce it. You could think that's not such a smart idea if you remember Grignard reagents or alkyllithiums. In fact, using trimethylaluminum with either of the other two metal alkyls is a bad idea. The trimethylaluminum swiftly decomposes into a species known as "methylalumoxane," which is a poorly characterised species.

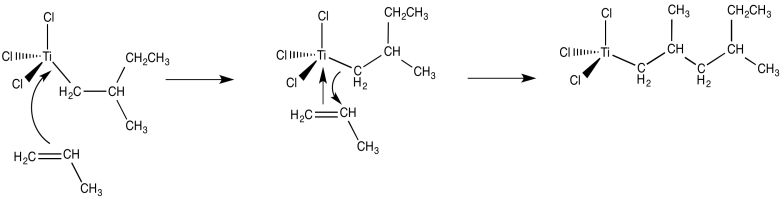

It's possible that our understanding of MAO's structure is a little hazy. Model studies can once again provide some light on the problem. Alkyl aluminium oxide clusters were created through the careful treatment of tri(tbutyl)aluminum with water in Andrew Barron's lab at Rice University. Depending on the reaction circumstances, aluminium oxide clusters of two, three, four, or six aluminium atoms occurred. Below is a drawing of one such example, a hexamer.

Oxide ligands have been used to replace some of the alkyl groups. We can envision what might happen if trimethylaluminum was used. Aluminum atoms create connections with oxygen, which act as a bridge between them. Although it must retain some methyl groups, the structure is most likely oligomeric, generating huge clusters of aluminium oxide.

Q4) Explain the Grignard reagent and Reactions of Grignard reagent.

A4)

Applications

The Ziegler-Natta catalyst polymerisation is a useful and adaptable polymerization reaction. This catalyst is employed in the manufacturing of high and low-density polyethylene, among other things.

Thermoplastic polyolefins, polybutylene, crystalline polypropylene, and carbon nanotube nanocomposites are all manufactured.

Limitation of Ziegler-Natta Catalyst

The Ziegler-Natta polymerization method has some drawbacks, as it does not operate with all monomers. Ziegler-Natta polymerisation cannot produce products like poly(vinyl chloride). Another example would be acrylates.

Problem: Draw the first intermediate generated during the cationic polymerization start phase of:

a. Ethene

b. Propene

Polyethylene and polypropylene, unlike the other polymers of alkenes we've looked at, are not polymerized via cationic techniques.

Instead, a method known as "Ziegler-Natta polymerisation" is used to enchain these monomers. This technique is named after two chemists, one from Germany and the other from Italy, who are both credited with developing it in the 1950s.

Monomers are treated with a catalyst, such as a combination of titanium chloride (or similar compounds, such as oxovanadium chloride) and triethylaluminum chloride, in Ziegler-Natta polymerisation (or trimethylaluminum). Other ingredients, such as magnesium chloride, are frequently added to change the catalyst and improve performance. The mixture generates a heterogeneous catalyst, which is a solid that is insoluble.

Because all of these components react together to create something new, the catalyst is no longer titanium chloride. It's possible that determining exactly what they create is difficult.

Despite the intricate catalyst mixture, we have a basic understanding of the reaction mechanism. This information is derived in part from investigations using model chemicals. Model compounds are less complex than industrial catalysts, yet they share some structural similarities with their more powerful cousins. They share enough similarities to perform polymerization catalysis, though perhaps not as well as the industrial heavyweights.

It appears that one of the functions of trialkylaluminum is to furnish titanium with an alkyl group. That shouldn't come as a shock. Like ethyllithium or ethylmagnesium bromide, triethylaluminum should be a source of nucleophilic ethyl groups. With halide leaving groups, titanium tetrachloride should be a rather good electrophile. At least one of the chlorides could be substituted with an ethyl ligand.

Ethylation of titanium tetrachloride with triethylaluminum requires a mechanism.

The binding of an alkene ligand to the transition metal could be the next step.

We're now dealing with an organotransition metal complex. Organometallic reaction processes should be considered. A 1,2-insertion of the alkene into the metal-carbon bond, for example, would result in a new metal alkyl.

From there, polymerization of propene can be easily imagined by repeating these basic processes in a sequential order. The propene dimer is formed by bonding an extra alkene followed by the 1,2-insertion of the propene into the metal-carbon bond (with a methyl end group).

- Alkene binding and insertion into metal-carbon bonds are involved in Ziegler-Natta polymerization.

- Let's take a step back and examine the role of the aluminium compound in greater detail. This topic is unrelated to electrophilic addition, although it is relevant to the field of catalysis.

- "Promoters" and "supports" are sometimes used in catalysis to improve catalyst function. They could accomplish it in a variety of ways. They may participate directly in the process, giving additional Lewis acidic or Lewis basic sites, similar to how amino acid residues surrounding an enzyme's active site may aid in catalysis. They may play a more subtle function, altering the catalyst's physical qualities (such as solubility) or even tuning up the catalyst's chemical properties. For instance, the promoter may increase the electron density of the catalyst, making it less electrophilic. That could make the catalyst more stable; it could also make it more selective, reacting more thoughtfully rather than recklessly. It's possible that it extends the catalyst's life.

- Although traditional Ziegler-Natta polymerization uses heterogeneous catalysis, there have been many modifications produced, including model systems for studying the reaction's fundamentals as well as alternative, working homogeneous catalysts. Walter Kaminsky of the University of Hamburg produced an effective version that uses Cp2ZrCl2 as a catalyst and methylalumoxane (MAO) as a promoter. A "zirconocene" is a zirconium species in which the zirconium atom is sandwiched between two cyclopentadienly ligands.

MAO is yet another species with a hazy definition. Trimethylaluminum is treated with a trace of moisture to produce it. You could think that's not such a smart idea if you remember Grignard reagents or alkyllithiums. In fact, using trimethylaluminum with either of the other two metal alkyls is a bad idea. The trimethylaluminum swiftly decomposes into a species known as "methylalumoxane," which is a poorly characterised species.

It's possible that our understanding of MAO's structure is a little hazy. Model studies can once again provide some light on the problem. Alkyl aluminium oxide clusters were created through the careful treatment of tri(tbutyl)aluminum with water in Andrew Barron's lab at Rice University. Depending on the reaction circumstances, aluminium oxide clusters of two, three, four, or six aluminium atoms occurred. Below is a drawing of one such example, a hexamer.

Q5) What is Synthesis of Ferrocene. Explain in brief.

A5)

Set up a stir bar in a 100-mL three-neck (14/20) round bottom flask (RBF). On the two side necks, attach septa. To make a powder, grind 4.0 g of KOH in a mortar and pestle. To avoid inhaling powders, do this in the fume hood. Because KOH is hygroscopic, you must work quickly. Pour the KOH into the RBF using a powder funnel. To wash down the residual KOH, pour 12 mL of 1,2-dimethoxyethane down the funnel. Substitute a dropping funnel for the powder funnel. Use a needle to vent the flask after sealing it with a septum and purging it with nitrogen. After about 10 minutes, use a syringe to add 1 mL of cyclopentadiene while stirring. The answer should change colour to pink. Small amounts of the cyclopentadiene anion have oxidised if the solution turns black or green. Wait 5 minutes while stirring, then place a venting needle into the septum to relieve the pressure. Remove the needle after the pressure has been removed.

Pulverize 1.3 g of FeCl2•4H2O and dissolve in 6 mL DMSO in a flask while the solution is swirling. Transfer to the funnel for dropping. To get quantitative transfer, rinse flask with 1mL DMSO. Add the FeCl2•4H2O at a rate of 20 drops per minute while stirring. Allow the reaction to stir for another 30 minutes after the FeCl2•4H2O has been added.

Prepare 20g of ice and 9 mL of 12M HCl in a 250 mL beaker, then transfer a tiny amount to a 25 mL beaker to wash the reaction flask. Stop the reaction, remove the dropping funnel, and pour the reaction mixture into the HCl-ice slurry carefully. Rinse the RBF in the 25 mL beaker with the additional HCl-ice slurry before adding it to the beaker. Stir constantly until the liquid is completely dissolved and the surplus potassium hydroxide has been absorbed. It is critical that the temperature of the mixture remain close to 0 °C during and after this addition. As needed, add more ice to the solution.

With a Hirsch funnel, filter paper, adapter, and filter flask, set up the filtering apparatus. Filter the contents of the beaker and collect the precipitate (ferrocene). Three parts of 10mL water were used to wash the ferrocene. Allow the ferrocene to dry out on a watch glass until the next lab.

Q6) Describe the Purification process of Ferrocene.

A6)

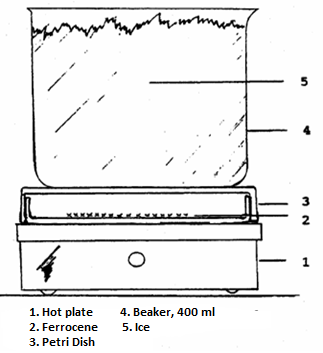

Ferrocene is a diamagnetic, crystalline substance that is exceptionally resistant to air, moisture, and light. In almost all nonpolar or weakly polar solvents, it is moderately to very soluble. Sublimation can be used to purify it.

Weigh the dried crude ferrocene and determine its melting point. [NOTE: All melting points must be taken in parafilm-sealed melting point tubes. Ferrocene sublimes at temperatures below its melting point, therefore it would escape from an open tube.]

As demonstrated in the diagram below, sublimation can be done in a 100 x 15 mm culture dish. Apply ferrocene to the "bottom" of the culture dish and spread it out to a thickness of about 5 mm in the centre. Place the culture dish on a variable temperature hot plate and cover with the bigger half of the culture dish. Raise the temperature gradually until the ferrocene has risen to the top half of the dish. The sublimation will be gradual. Sublimation will be aided by cooling the top culture plate by placing a beaker filled with ice water on top of it. (WARNING: Remove the beaker from the culture dish's top.) Lifting it could cause the upper culture dish to fall or disturb the sublimed ferrocene, resulting in ferrocene loss.) Remove the dish from the heat, set it aside to cool, and then reassemble the sublimed ferrocene. This method can be repeated until all of the ferrocene has been purified. Do not heat to more than 100 degrees Celsius. When there is a layer of ferrocene on the top of the culture dish, students can remove it and replace it with another higher culture dish. Repeat until there is no orange result on the bottom.

Calculate the melting point of each batch of sublimed ferrocene. Place the finished product in a weighted vial and calculate the yield, as well as the melting point. Calculate your real % yield and report it. The melting point should be 171 °C or higher (lit. 173-174 °C).

Q7) Describe Synthesizing Acetylferrocene & Chromatography.

A7)

You'll use phosphoric acid and acetic anhydride to acetylate ferrocene and thin layer chromatography to count the number of products. Scale down every reagent dependent on the ferrocene that will be used in this part if we don't have enough.

Preheat a 10 mL round bottom flask with a stir bar in a 65 °C water bath. 1.0 mmol ferrocene, 0.7 mL acetic anhydride, and 0.2 mL 85 percent phosphoric acid are added to the mixture. You will successfully decompose the ferrocene if you do not add the reactants in this order. Insert a venting needle and close the round bottom with a septum. Warm the solution, stirring constantly, until the ferrocene dissolves, then heat it for 30 minutes. Cool the round bottom thoroughly in an ice bath, then add 0.5 mL of ice water to the liquid while stirring. Add 3 M aqueous sodium hydroxide solution drop by drop until the pH of the solution is neutral (somewhere between 20-30 drops). Fill a filter funnel halfway with the product and rinse the sediments with water. To get the product as dry as possible, press it using filter paper. The crystals are allowed to dry naturally. Take the crude product's yield and melting point.

Q8) Write a short note on Procedure for TLC & Column Chromatography.

A8)

Thin-layer chromatography will be used to determine the distribution of products in your acetylation reaction.

Place a few (5 to 10) drops of methylene chloride, CH2Cl2, in two tiny vials to make solutions of your sublimed ferrocene and dried acetylation product. In one vial, put a little amount of ferrocene (one spatula-tip full) and the acetylation result in the other. After application, the solution should be concentrated enough to leave a dark mark on the TLC plate. If spots on the TLC plate are not visible, add more sample to the solutions and try again. (You can use the same TLC plate as before; simply add the highly concentrated solution directly on top of the first sample.)

The purpose of this part of the experiment is to find the appropriate hexane to ethyl acetate ratio for separating the different ferrocene compounds. The separation of products as a function of solvent polarity is the principle used here.

Begin by separating the products with a pure solvent (hexane or ethyl acetate). After you've gotten those results, choose whole number solvent combination ratios and test them in the same way (i.e., 1:4 hexane to ethyl acetate). TLC plates can be bought at the pharmacy, and micro-capillary tubes will be used as applicators. As illustrated in the illustration, place a piece of filter paper in a tiny jar with a lid and carefully pour in the solvent. Make sure the solvent level is below the point where the TLC plate is visible. On the TLC plate, draw a line to indicate the beginning solvent, then use the capillary to position the TLC plate just above the solvent line. Place the stained TLC plate into the solvent jar with care and cover with a lid. Allow the plate to develop in the solvent until the product spots are 1 cm from the plate's top. If you keep the plate in the solvent for too long, the spots will concentrate at the top and you won't be able to make any useful observations. In your lab notebook, doodle each chromatogram result and make a note of the solvent ratio you used for that plate. Calculate the ratio to front (Rf) value for each spot after obtaining a TLC plate with good separation (no smearing of spots, no spot overlap, etc.).

Q9) Explain the Characteristics of Specific Substitution Reactions.

A9)

Halogenation: | C6H6 | + Cl2 & heat | ——> | C6H5Cl | + HCl |

Nitration: | C6H6 | + HNO3 & heat | ——> | C6H5NO2 | + H2O |

Sulfonation: | C6H6 | + H2SO4 + SO3 | ——> | C6H5SO3H | + H2O |

Alkylation: | C6H6 | + R-Cl & heat | ——> | C6H5-R | + HCl |

Acylation: | C6H6 | + RCOCl & heat | ——> | C6H5COR | + HCl |

The table on the right repeats the conditions usually used for the aromatic substitution reactions mentioned here. These reagents have varying electrophilic reactivity. For example, we discovered that nitrobenzene nitration happens smoothly at 95 oC, yielding meta-dinitrobenzene, whereas nitrobenzene bromination (ferric catalyst) requires a temperature of 140 oC. Also, as previously stated, toluene nitrates around 25 times quicker than benzene, whereas toluene chlorinates approximately 500 times quicker than benzene. We can deduce that the nitration reagent is more reactive and less selective than the halogenation reagents based on this.

Water is produced as a by-product of both sulfonation and nitration. The nitration reaction remains unaffected (notice the presence of sulfuric acid as a dehydrating agent), but sulfonation is reversible and is accelerated by the addition of sulphur trioxide, which transforms the water to sulfuric acid. The reversibility of the sulfonation process can be used to remove this functional group on occasion.

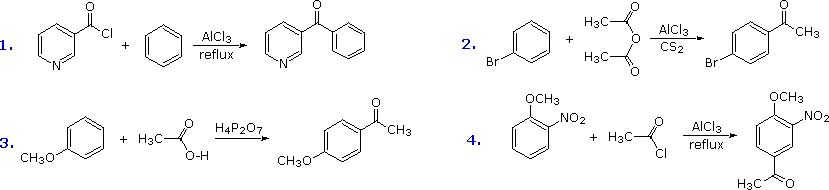

Friedel-Crafts acylation reagents are usually made up of an acyl halide or anhydride and a Lewis acid catalyst like AlCl3. This results in the formation of an acylium cation, R-CO(+), or a similar species. Because such electrophiles aren't particularly reactive, acylation is usually limited to aromatic systems that are at least as reactive as chlorobenzene. Because it is non-reactive and easily removed from the product, carbon disulfide is frequently employed as a solvent. If the substrate is a highly reactive benzene derivative like anisole, the acylating electrophile could come from carboxylic esters or acids. The figure below shows some examples of Friedel-Crafts acylation reactions. The first highlights the possibility of using uncommon acylating chemicals as reactants. The second uses an anhydride acylating reagent, while the third shows how easily anisole reacts, as previously mentioned. The H4P2O7 reagent utilised here is pyrophosphoric acid, a phosphoric acid anhydride. Finally, the fourth example highlights a few key issues. Friedel-Crafts acylation of nitrobenzene does not occur under any circumstances because the nitro group is a strong deactivating substituent. The presence of a second strongly-activating substituent group, on the other hand, allows acylation; the reaction site is preferred by both substituents.

A common characteristic of the halogenation, nitration, sulfonation and acylation

The introduction of a deactivating substituent on the benzene ring is a key feature of these reactions. As a result, we rarely have to be concerned about disubstitution products forming. Friedel-Crafts alkylation, on the other hand, involves the addition of an activating substituent (an alkyl group), allowing for many substitutions. When benzene is alkylated, as in the following synthesis of tert-butylbenzene, a substantial excess of this reactant favours the mono-alkylated product. When the molar ratio of benzene to alkyl halide is less than 1:1, the main result is para-ditert-butylbenzene.

C6H6 (large excess) + (CH3)3C-Cl + AlCl3 ——> C6H5-C(CH3)3 + HCl

Alkyl halides (as mentioned above), alkenes + strong acid, and alcohols + strong acid can all be used to make the carbocation electrophiles needed for alkylation. Because 1o-carbocations are prone to rearrangement, Friedel-Crafts alkylation is rarely used to introduce 1o-alkyl substituents greater than ethyl. Excess benzene, for example, can be converted to isopropylbenzene by reacting it with 1-chloropropane and aluminium chloride (cumene).

——> C6H5-CH(CH3)2 + HCl ——> C6H6 (large excess) + CH3CH2CH2-Cl + AlCl3 ——> C6H5-CH(CH3)2 + HCl

Q10) Write a short note on Substitution reaction of Benzene derivative.

A10)

When substituted benzene compounds go through electrophilic substitution processes, there are two things to keep in mind:

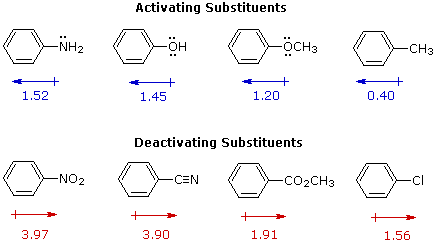

The first is the compound's relative reactivity in comparison to benzene. Experiments have demonstrated that the substituents on a benzene ring have a significant impact on reactivity. A hydroxy or methoxy substituent, for example, boosts the rate of electrophilic substitution by ten thousand times, as seen in the virtual demonstration with anisole (above). A nitro substituent, on the other hand, reduces the ring's reactivity by a factor of a million. The electron donating or electron withdrawing influence of the substituents, as measured by molecular dipole moments, may be associated with the activation or deactivation of the benzene ring toward electrophilic substitution. The benzene ring is activated for electrophilic attack by electron giving substituents (blue dipoles), while electron withdrawing substituents (red dipoles) deactivate the ring (make it less reactive to electrophilic attack).

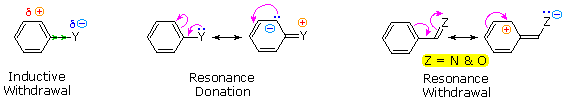

The interaction of two effects can explain the influence of a substituent on the reactivity of a benzene ring:

The first is the substituent's inductive impact. Except for metals and carbon, most elements have a far higher electronegativity than hydrogen. As a result, substituents containing nitrogen, oxygen, or halogen atoms form sigma bonds with the aromatic ring, causing inductive electron removal and ring deactivation (left-hand diagram below).

The second impact occurs when a substituent function is conjugated to an aromatic ring. In contrast to the inductive shift, this conjugative interaction permits electron pair donation or withdrawal to or from the benzene ring. Electrons may flow into the aromatic ring via p-conjugation (resonance) if the atom connected to the ring has one or more non-bonding valence shell electron pairs, as do nitrogen, oxygen, and the halogens. Finally, as seen in the right-hand picture, polar double and triple bonds conjugated to the benzene ring can remove electrons. It's worth noting that none of the donors are shown in the resonance examples. The charge distribution in the benzene ring is largest ortho and para to the substituent in both circumstances.

Q11) Describe A Mechanism for Electrophilic Substitution Reactions of Benzene.

A11)

For these electrophilic substitution reactions, a two-step mechanism has been proposed. In the first, slow or rate-determining, step the electrophile forms a sigma-bond to the benzene ring, generating a positively charged benzenonium intermediate. A proton is removed from this intermediate in the second, quick step, yielding a substituted benzene ring. This mechanism for the bromination reaction is depicted in the four-part diagram below. There's also an animated diagram to look at.

Bromination of Benzene - An Example of Electrophilic Aromatic Substitution

This method for electrophilic aromatic substitution should be viewed in the context of other carbocation intermediate-based methods. Alkyl halide SN1 and E1 reactions, as well as alkene Brnsted acid addition reactions, are examples.

To summarize, when carbocation intermediates are formed one can expect them to react further by one or more of the following modes:

1. The cation can form a substitution or addition product by bonding to a nucleophile.

2. A proton may be transferred from the cation to the base, resulting in a double bond product.

3. The cation may rearrange into a more stable carbocation, after which it will react in mode #1 or #2.

The first two forms of reaction are represented by the SN1 and E1 reactions, respectively. The first mode is used in the second phase of alkene addition reactions, and any of these three processes might result in molecular rearrangement if an initial unstable carbocation is generated. Charge delocalization (resonance) stabilises the carbocation intermediate in electrophilic aromatic substitution (the benzenonium ion), preventing rearrangement. In theory, it could react in either mode 1 or 2, but the energy benefit of recreating an aromatic ring makes mode 2 the only option (ie. Proton loss).

Q12) Describe the structure of Aromatic Compounds.

A12)

Aromatic Compounds: Structure:

Because of their distinct scents, benzene-like compounds were previously referred to as aromatic hydrocarbons. An aromatic compound is now defined as any chemical with a benzene ring or some benzene-like characteristics (but not necessarily a strong aroma). The presence of one or more benzene rings in the structure of the aromatic compounds in this text makes them easy to identify. Table lists several example aromatic compounds and their applications, with the benzene ring denoted as C6H5.

Table: Some Representative Aromatic Compounds | ||

Name | Structure | Typical Uses |

Aniline | C6H5–NH2 | Starting material for the synthesis of dyes, drugs, resins, varnishes, perfumes; solvent; vulcanizing rubber |

Benzoic acid | C6H5–COOH | Tobacco curing; food preservation; starting material for the production of colours and other chemical chemicals |

Bromobenzene | C6H5–Br | Solvent; motor oil additive; starting ingredient for the production of several other aromatic compounds |

Nitrobenzene | C6H5–NO2 | Starting material for aniline production; cellulose nitrate solvent; used in soaps and shoe polish |

Phenol | C6H5–OH | a disinfectant; a raw ingredient for the manufacture of resins, medicines, and other chemical compounds. |

Toluene | C6H5–CH3 | Solvent; gasoline octane booster; precursor to benzoic acid, benzaldehyde, and a variety of other chemical compounds |

Q13) State any 2 rules of Aromaticity.

A13)

1. Four Key Rules for Aromaticity

There are four characteristics that a molecule must satisfy in order to be aromatic.

It's a case of all or nothing. Aromaticity cannot be achieved if any of these requirements are not met.

- It must first be cyclic.

- Second, each of the ring's atoms must be conjugated.

- Third, the molecule must have [4n+2] pi electrons (we'll go over this in detail later).

- The fourth requirement is that the molecule be planar (usually true if conditions 1-3 are met, but there are rare exceptions)

- Let's take a closer look.

2. Condition #1 for Aromaticity: The Molecule Must Be Cyclic

It's rather simple to tell if a molecule is cyclic. Is there a ring on the finger? If you answered yes, proceed to condition #2. If there isn't a ring, don't bother.

Consider the following example: Although it has the same amount of pi bonds (and pi electrons) as benzene, (Z)-1,3,5 hexatriene is not aromatic. There is no ring, and there is no aromaticity.

Q14) Explain the Mechanism of Ziegler–Natta Catalyst.

A14)

The Ziegler-Natta catalyst is used in coordination polymerisations, and it involves complexes produced between a transition metal and a monomer's electrons. Polymerisation is normally accomplished through the insertion of monomers at the expanding chain's end, where the transition metal ions are attached. The entering monomers are coordinated at unoccupied orbital locations at the same time, resulting in the production of long polymer chains. At the active core, the C=C bond is also introduced into the TiC bond. Finally, the chain-growth polymerisation reaches the termination step, where “dead” polymers (the desired result) are created. These processes are similar to anionic polymerisation, which produces linear and stereo-regular polymers.

Q15) Describe the Multicenter bonding.

A15)

When there aren't enough electrons in a molecule to allow at least one electron pair link between neighbouring pairs of atoms, this form of bonding happens.

There are eight neighbouring atoms and only six pairs of electrons available for bonding in the simplest borane, diborane. Eight bonds are required to provide the usual distribution of two-center two-electron (2c-2e) bonding. This could be explained by a resonance structure with two canonical forms. This would lead to the conclusion that one electron pair is dispersed over two B-H bonds, resulting in a bond order of one half. A B-H-B bridge would result as a result of this. The molecule's remaining B-H bonds would be standard 2c-2e bonds. The subject could also be investigated utilising the Molecular Orbital(MO) theory. This method solely considers the bridging system, and the terminal B-H groups are treated independently as localised elctron-pair bonds. As a result, an H-B-H group with comparable sp(3) hybridised orbitals has two ordinary B-H bonds and only one accessible hybridised orbital. If two such groups of H-B-H were brought together, the remaining hydrogens would occupy a bridging posture, and an orbital would develop that would bridge over the hydrogens, with the free single hybridised orbitals in each molecule facing each other. A graphical illustration of this can be found below.

The ' + ' represent the free hybridized orbitals in the molecules.

H + + H

\ + + /

B B

/ + + \

H + + H

The remaining hydrogen's have taken up their bridging position's, with the 1s orbitals of the hydrogens overlapping with two sp(3) orbitals of the hydrogens. This forms two orbitals which extend over each B--H--B unit.

Q16) Explain the Role of triethyl aluminium in polymerization of ethane (Ziegler –Natta Catalyst)

A16)

Any of a class of chemical compounds known for their capacity to polymerize olefins (hydrocarbons with a double carbon–carbon bond) to polymers with large molecular weights and highly ordered (stereoregular) structures is known as a Ziegler-Natta catalyst.

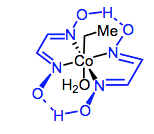

For the polymerization of ethylene at atmospheric pressure, German chemist Karl Ziegler developed these catalysts in the 1950s. Ziegler used a titanium tetrachloride catalyst with an alkyl derivative of aluminium as a catalyst. Based on his insights on the mechanism of the polymerization reaction, Giulio Natta, an Italian scientist, expanded the process to other olefins and produced other versions of the Ziegler catalyst. Many Ziegler-Natta catalysts combine transition metal halides, such as titanium, chromium, vanadium, and zirconium, with nontransition metal organic derivatives, particularly alkyl aluminium compounds.

Q17) What are Stable Alkyl Complexes.

A17)

Stable Alkyl Complexes

By raising to 18 e-'s, one can avoid beta-hydride removal and stabilise desirable species. All of the orbitals of a transition metal-alkyl complex with 18 e-'s are full capacity, and there is no contact between the beta-hydrogen and the transition metal centre. Another option is to use stable alkyl ligands that don't have beta-hydrogens and can't be eliminated. WMe6, Ti(CH2Ph)4, and C2F5Mn(CO)5 [5] are examples of alkyls without beta-hydrogens. The orientation of ligands can also be employed to prevent beta-hydrogen elimination by orienting the alkyl in such a way that steric hindrance inhibits the beta-hydrogen from accessing the metal centre. PdPh2L2, Cr(CMe3)4, and Cr(CHMe3)4 are examples of bulky alkyls in which the beta-hydrogen cannot contact the metal due to the orientation or bulkiness of the ligand. A third strategy is to use alkyls that produce an unstable alkene as a result of the reaction.

The blue ligands "trap" the transition metal center and prevent the coordination site from being.

Metal-alkyl studies are important because they are important in organometallic and catalytic systems and contexts. There was speculation about thermodynamics and kinetic instability of metal-C sigma bonds before metal alkyls were properly examined and evaluated, determining that it was really kinetics instability that made it difficult for organometallic chemists to isolate metal alkyls. Regardless, metal alkyl has a variety of important applications, as detailed in Applications of Metal Carbonyl Anions in the Synthesis of Unusual Organometallic Compounds, and is utilised in the Strem Chemicals company for chemical vapour deposition, atomic layer deposition, and other processes (defined in their website). In essence, it is beneficial to compare and contrast various metal alkyl complexes in order to establish predictions about their properties and behaviour.

Q18) Enlist the Eliminations of Metal Alkyl Complexes.

A18)

Eliminations

Decomposition routes with low activation barriers are often susceptible to most metal alkyls. Beta-hydride elimination is the most prevalent mechanism, followed by reductive elimination, which is the second most common process.

Beta-hydride elimination

The transfer of a hydrogen atom from the ligand to the metal centre of the complex, as seen in Figure, is known as beta-hydride elimination. To avoid this, alkyls must not contain -hydrogens, which result in an unstable alkene because the positioned hydrogen is unable to access the metal. The -carbon must contain a hydrogen, and the metal-carbon and carbon-hydrogen bonds must be in a syn-coplanar orientation to allow for elimination.

- There must be a public coordination site.

- The metal must contain no more than 16 e-'s and be at least d2.

Figure: Beta-hydride Elimination

Reductive Elimination

As demonstrated in Figure, reductive elimination entails removing a molecule from a transition metal complex where the metal has been reduced by two electrons. With groups being deleted in the cis orientation, elimination happens. The elimination process can be aided by an unstable oxidative state. The alkyl ligand interacts with a second type of ligand on the metal, causing the metal to be reduced by two units, resulting in a total electron count decrease of two. When X = H, reductive elimination is often thermodynamically advantageous. When X = halogen, however, reductive elimination is not advantageous.

Q19) Explain the discovery of Ziegler-Natta catalyst.

A19)

In the year 1950, a German chemist named Karl Ziegler demonstrated the use of the catalyst during the polymerisation of ethylene for the first time. A combination of an alkyl derivative of aluminium and titanium tetrachloride served as his catalyst. While the reaction was a success, an Italian chemist named Giulio Natta expanded the process to include more olefins. He produced numerous variants of the catalyst based on his research into the mechanism of polymerisation.

However, the primary mechanism of their catalysts was that it facilitated the synthesis of stereospecific, unbranched polyolefins with high molecular weight. In 1963, Ziegler and Natta were awarded the Nobel Prize for their work.

Q20) State the preparation of of Ziegler-Natta.

A20)

Today's Ziegler-Natta catalysts typically comprise a variety of transition metal halides, such as titanium, vanadium, chromium, and zirconium, as well as organic non-transition metal derivatives, particularly alkyl aluminium compounds.

Transition metal halides belonging to groups IV-VIII are commonly interacted with organometallic compounds belonging to groups I – III in the contemporary periodic table to prepare or acquire Ziegler-Natta catalysts. A blend of titanium tetrachloride (TiCl4) and trimethylaluminum (Al(C2H5)3) is a popular example. The catalysts have shown to be really beneficial.

The Ziegler–Natta catalysts that are used fall into one of two groups, which are characterised by their solubility. The following are the catalysts:

- Catalyst with a heterogeneous support. These are titanium compounds-based catalysts. During polymerisation reactions, they are combined with organoaluminum compounds and cocatalysts.

- Catalysts that are homogeneous. These are based on Hf, Ti, or Zr complexes. Metallocenes are common, although they also contain nitrogen-based and multidentate oxygen-based ligands